Noise vibration is the main protection measure. Noise and vibration. Basic protection measures. The main activities to combat noise are

on the subject: "Life safety"

on this topic:" Industrial vibration and industrial noise. Their influence on a person

Perm-2007

Industrial vibration

Vibration is understood as the reciprocating motion of a rigid body. This phenomenon is widespread in the operation of various mechanisms and machines. Sources of vibration: bulk conveyors, rock drills, electric motors, etc.

Basic vibration parameters: frequency (Hz), vibration amplitude (m), vibration period (s), vibration velocity (m / s), vibration acceleration (m / s²).

Depending on the nature of the worker's contact with vibrating equipment, local and general vibration are distinguished. Local vibration is transmitted mainly through the limbs of the arms and legs. There is also a mixed vibration that affects both the limbs and the entire human body. Local vibration occurs mainly when working with vibrating hand tools or bench-top equipment. General vibration is predominant in transport vehicles, heavy machinery manufacturing plants, elevators, etc., where floors, walls or equipment foundations vibrate.

The impact of vibration on the human body. The human body is considered as a combination of masses with elastic elements that have natural frequencies, which for the shoulder girdle, hips and head relative to the supporting surface ("standing" position) are 4-6 Hz, the head relative to the shoulders ("sitting" position) - 25-30 Hz. For most internal organs natural frequencies are in the range of 6-9 Hz. General vibration with a frequency of less than 0.7 Hz, defined as rolling, although unpleasant, does not lead to vibration sickness. The consequence of this vibration is motion sickness, caused by disruption of the normal activity of the vestibular apparatus due to resonance phenomena.

Systematic exposure to general vibrations leads to vibration disease, which is characterized by disorders physiological functions organism associated with damage to the central nervous system... These disorders cause headaches, dizziness, sleep disturbances, decreased performance, deterioration in well-being, cardiac disorders.

Local vibration of low intensity can have a beneficial effect on the human body, restore trophic changes, improve the functional state of the central nervous system, accelerate wound healing, etc.

With an increase in the intensity of vibrations and the duration of their impact, changes occur, leading in some cases to the development of occupational pathology- vibration disease.

Vibration levels.

General vibration is normalized taking into account the properties of the source of its occurrence and is divided into vibration:

· Transport, which arises as a result of the movement of cars on the ground and roads;

· Transport and technological, which occurs during the operation of machines performing a technological operation in a stationary position, as well as when moving around a specially prepared part of a production facility, an industrial site or at wholesale depots;

· Technological, which arises during the operation of stationary machines or is transferred to workplaces that do not have sources of vibration (for example, from the operation of refrigeration, filling and packaging machines).

· High demands are made in the regulation of technological vibrations in rooms for mental labor (management. Control room, accounting, etc.). The hygienic vibration standards are established for a working day lasting 8 hours.

The effect of vibration on the human body

Methods for Reducing Human Exposure to Vibration

To reduce the impact of vibrating machines and equipment on the human body, the following measures and means are applied:

· Replacement of tools or equipment with vibrating working bodies for non-vibrating ones in processes, where possible (for example, replacing electromechanical cash registers with electronic ones);

· The use of vibration isolation of vibrating machines relative to the base (for example, the use of springs, rubber gaskets, springs, shock absorbers);

· The use of automation in technological processes where vibrating machines operate (for example, control according to a given program);

· Use of remote control in technological processes (for example, the use of telecommunications to control a vibotransporter from an adjacent room);

· Use of hand tools with vibration-proof handles, special shoes and gloves.

· Besides technical means and methods to reduce the impact of vibration on a person, it is necessary to carry out hygienic and treatment-and-prophylactic measures. In accordance with the regulation on the working regime of workers in vibration-hazardous professions, the total time of contact with vibrating machines, the vibration of which complies with sanitary standards, should not exceed 2/3 of the working day.

Persons at least 18 years of age are allowed to work with vibrating machines and equipment. Those who have received the appropriate qualifications, passed the technical minimum for safety rules and passed a medical examination.

To increase the protective properties of the body, working capacity and labor activity, industrial gymnastics complexes, vitamin prophylaxis should be used (2 times a year a complex of vitamins C, a nicotinic acid), special meals. It is also advisable to carry out in the middle or at the end of the working day 5 - 10-minute hydro-procedures, combining baths at a water temperature of 38 ° С

There are sources of noise in various sectors of the economy - these are mechanical equipment, human flows, urban transport.

Noise is a collection of aperiodic sounds of varying intensity and frequency (rustling, rattling, creaking, squealing, etc.). From a physiological point of view, noise is any sound that is perceived unfavorably. Prolonged exposure to noise can cause such occupational disease like "noise sickness".

In physical essence, noise is a wave-like motion of particles of an elastic medium (gas, liquid or solid) and therefore is characterized by the amplitude of the vibration (m), frequency (Hz), propagation velocity (m / s) and wavelength (m). The loudness of the noise is determined by the subjective perception of the human hearing aid. The threshold of auditory perception also depends on the frequency range. Thus, the ear is less sensitive to low-frequency sounds.

The impact of noise on the human body causes negative changes primarily in the organs of hearing, nervous and cardiovascular systems... The severity of these changes depends on the parameters of noise, length of service under conditions of exposure to noise, duration of exposure to noise during the working day, and individual sensitivity of the organism. The effect of noise on the human body is aggravated by the forced position of the body, increased attention, neuro-emotional stress, and an unfavorable microclimate.

The effect of noise on the human body. To date, numerous data have been accumulated that allow one to judge the nature and characteristics of the influence of the noise factor on the auditory function. The course of functional changes can have various stages. Short-term decrease in hearing acuity under the influence of noise with quick recovery functions after the termination of the factor is considered as a manifestation of the adaptive protective-adaptive response of the auditory organ.

Adaptation to noise is considered to be a temporary decrease in hearing by no more than 10-15 dB with its restoration within 3 minutes after the cessation of the noise. Prolonged exposure to intense noise can lead to over-irritation of the cells of the sound analyzer and its fatigue, and then to a permanent decrease in hearing acuity.

It has been established that the exhausting and damaging hearing effect of noise is proportional to its height (frequency). The most pronounced and early changes are observed at a frequency of 4000 Hz and a frequency range close to it. In this case, impulse noise (at the same equivalent power) acts more unfavorably than continuous noise. The peculiarities of its impact significantly depend on the excess of the pulse level above the level that determines the noise background at the workplace.

The development of occupational hearing loss depends on the total time of exposure to noise during the working day and the presence of pauses, as well as the total length of service. Initial stages occupational injuries are observed in workers with an experience of 5 years, pronounced (hearing impairment at all frequencies, impaired perception of whispering and colloquial speech) - over 10 years.

In addition to the effect of noise on the organs of hearing, its harmful effect on many organs and systems of the body has been established, primarily on the central nervous system, functional changes in which occur earlier than a violation of auditory sensitivity is diagnosed. The defeat of the nervous system under the influence of noise is accompanied by irritability, weakening of memory, apathy, depressed mood. Changes in skin sensitivity and other disorders, in particular, the speed of mental reactions slows down, sleep disorders occur, etc. For knowledge workers, there is a decrease in the pace of work, its quality and productivity.

Noise(sound) - elastic vibrations in the frequency range of human hearing, propagating in the form of a wave in gaseous media.

Sound is a wave motion of an elastic medium (for example, air, water, etc.), which is perceived by a human hearing aid. The main characteristics of sound in accordance with GOST 12.1.003-83 SSBT “Noise. General requirements safety "and SanPiN 2.2.4 / 2.1.8.10-32-2002" Noise at workplaces, in residential and public buildings and in residential areas. "

Industrial noise- a set of sounds of varying intensity and frequency, randomly changing over time and causing unpleasant sensations in workers.

Constant noise- noise, the sound level of which during an 8-hour workday or work shift changes in time by no more than 5 dBA when measured on the standardized time characteristic of the measuring device "slowly".

Intermittent noise- noise, the sound level of which during an 8-hour work day or work shift changes in time by more than 5 dBA when measured on the standardized time characteristic of the measuring device "slowly". Intermittent noise is divided into oscillating, intermittent and impulsive.

Fluctuating noise- noise, the sound level of which changes continuously over time.

Intermittent noise- noise, the sound level of which changes stepwise with time (by 5 dBA or more), while the sound levels measured on the standardized time characteristics "impulse" and "slow" differ by less than 7 dBA.

Impulse noise- noise, consisting of one or more sound signals, for which the sound levels measured on the standardized time characteristics "impulse" and "slow" differ by 7 dB A or more.

Broadband noise has a continuous spectrum of more than one octave, tonal(discrete) contains in the spectrum pronounced discrete tones (frequencies, the sound level at which is significantly higher than the sound level at other frequencies). The noise of a jet plane is broadband noise, the noise of a circular saw is tonal (there is a pronounced frequency in the noise spectrum with a dominant sound level).

Mechanical noise arise due to the presence of inertial disturbing forces in the mechanisms, collision of parts, friction, etc. Aerodynamic noise arise as a result of gas movement, gas (air) flows around various bodies. Aerodynamic noise occurs during the operation of fans, blowers, compressors, gas turbines, steam and gas emissions into the atmosphere, etc. Hydraulic noise arise as a result of stationary and non-stationary processes in liquids.

Electromagnetic noise occur in electrical machines and equipment that use electromagnetic energy.

Sound range noise in manufacturing leads to decreased attention and increased errors in work performance. As a result, labor productivity decreases and the quality of the work performed deteriorates. Noise slows down a person's reaction to signals coming from technical objects and in-shop transport, which contributes to the occurrence of industrial accidents.

Sounds that exceed the pain threshold can cause pain and damage in the hearing aid (perforation or even rupture of the eardrum). The area on the frequency scale that lies between the two curves is called the area of auditory perception.

Noise with a sound pressure level of up to 30 ... 45 dB is familiar to a person and does not bother him. An increase in the sound level to 40 ... 70 dB creates an additional load on the nervous system, causes a deterioration in well-being and, with prolonged exposure, can cause neuroses.

Prolonged exposure to noise levels above 80 dB can lead to hearing impairment - occupational hearing loss. Under the action of noise above 130 dB, rupture of the eardrums, contusion is possible, and at sound levels above 160 dB, death is likely.

Maximum permissible noise level- a level that, with daily (except weekends) work, but not more than 40 hours per week during the entire working experience, should not cause diseases or deviations in the state of health detected modern methods research, in the process of work or in remote periods of life of the present and subsequent generations.

Subjective sensations of a person from exposure to noise depend not only on the level of sound pressure, but also on frequency. Low frequency sounds are perceived to be less loud compared to higher frequency sounds of the same intensity.

Volume level(unit background)- the difference in loudness levels of two sounds of a given frequency, for which sounds of equal loudness with a frequency of 1000 Hz differ in intensity (or sound pressure level) by 1 dB.

At frequencies below 1000 Hz, the loudness levels are lower than the sound pressure levels, and, conversely, at higher frequencies

the volume levels are higher than the sound pressure levels. Consequently, the concept of "loudness level" is a purely physiological characteristic of sound.

Measurements of noise levels in a production environment are made with sound level meters.

Frequency spectrum constant noise is the frequency dependence of the rms sound pressure.

In production conditions, various machines, apparatus and mechanisms are dynamically unbalanced units. The consequence of their work is noise and vibration, the systematic effect of which inevitably leads to a negative effect on the human body and to a decrease in his labor productivity.

Some information about noise

Sound is a specific sensation caused by the action of sound waves on the organs of hearing.

The human hearing aid perceives sound vibrations with a frequency of 16 to 20,000 Hz. Sounds with a frequency below 16 Hz (infrasounds) and with a frequency above 20,000 Hz (ultrasounds) are not audible to humans.

Noise is a complex sound consisting of a combination of sounds of different frequency and intensity.

Sound intensity is the amount of energy carried by a sound wave in 1 second through an area of 1 cm 2 perpendicular to the movement of the wave. The human ear is not sensitive to intensity, but to sound pressure, the magnitude of which is related to intensity. The maximum and minimum sound pressures and intensities perceived by humans as sound are called thresholds. The minimum values are hearing threshold- correspond to barely perceptible sounds; maximum - pain threshold, - when the sound is not felt as a sound, but only causes pain. In practice, it is customary to use not the absolute values of sound pressures and intensities, but their levels. Sound pressure and intensity levels are measured in decibels (dB).

The human auditory perception limit is 140 dB; an intensity level of 150 dB is unbearable for humans; 180 dB causes metal fatigue; 190 dB pulls out rivets from steel structures.

In addition, according to the change in time, the noises are divided into stable and intermittent... Howling and intermittent noises have an especially adverse effect on a person.

GOST 12.1.003–88 establishes the classification of noise, acceptable levels noise in the workplace, general requirements for the noise characteristics of machines, mechanisms, vehicles and other equipment and for noise protection.

Effect of noise on the human body

Long-term systematic exposure to noise on the human body leads to the following consequences of noise sickness:

labor productivity decreases. The number of errors in calculation work increases by 50%;

memory, attention, visual acuity and sensitivity to warning signals are weakened;

hearing sensitivity decreases;

violated blood pressure and the rhythm of cardiac activity.

The main activities to combat noise are:

Correct organization of work and rest (arrangement of short breaks in work).

Correct layout and location of workshops. Areas with noisy production should be located on the leeward side and at a sufficient distance to reduce the noise level.

High-quality manufacturing of machine and machine parts.

Replacement of metallic colliding parts with non-metallic ones.

Since sound absorption is based on the phenomenon of resonance and the greatest effect occurs when the frequencies of the incident sound wave and the natural vibrations of the sound-absorbing panel coincide, it is advisable to use it where low-frequency (up to 300 Hz) noises prevail.

The use of soundproofing barriers. The soundproofing ability of obstacles increases with an increase in their weight and frequency of sound waves.

The use of noise mufflers.

The use of personal protective equipment (tampons, ear muffs, headsets, etc.).

Some facts about vibration

Vibration is physically characterized by frequency, amplitude, speed, and acceleration.

The threshold sensation of vibration occurs in a person when the acceleration of vibration reaches 1% of the normal acceleration of gravity (approximately 0.1 m / s 2), and an unpleasant, painful sensation occurs when the acceleration reaches 4 ... 5% of the normal acceleration of gravity (approximately 0 , 4 ... 0.5 m / s 2).

The problem of rationing of industrial vibrations is solved in two directions: engineering and technical and sanitary and hygienic.

The vibration frequency is of great hygienic importance. The amplitude of the maximum permissible vibrations should decrease sharply with increasing frequency. GOST 12.1.012–90 and SN 2.2.4 / 2.18.566–98 “Vibration. General Safety Requirements ”establishes the classification and hygienic standards of vibration, requirements for vibration characteristics of production equipment, including vehicles, requirements for vibration protection and vibration control methods.

However, in practice, the most dangerous may be vibrations with frequencies close to the frequencies of natural vibrations of individual organs of the human body (6 ... 9 Hz).

The effect of vibration on the human body

Vibration, in addition to a destructive effect on machines and mechanisms (statistics show that about 80% of breakdowns and accidents in mechanical engineering are the result of unacceptable vibrations), has a harmful effect on human health. Under the influence of vibration, the following occurs:

oppression of the peripheral nervous system;

weakening of memory;

drop in muscle strength and weight;

increased energy consumption of the body;

changes in the nervous and osteoarticular systems;

increased blood pressure;

spasms of the blood vessels of the heart;

gangrene of the limbs.

Vibration disease belongs to a group of diseases, the effective treatment of which is possible only in the early stages, and the restoration of the impaired functions occurs very slowly, and under some conditions irreversible processes occur, leading to disability.

Thus, the complete elimination or reduction of noise and vibration levels is one of the indispensable conditions for improving working conditions and improving the technical culture of production.

Basic measures to combat vibration:

Correct organization of work and rest:

- short breaks in work (10 ... 15 minutes every 1 ... 1.5 hours of work);

- active hand gymnastics, warm water baths for the limbs, etc.

Vibration isolation - the use of spring, rubber and other shock absorbers or elastic pads.

The following are used as shock absorbers:

slabs of mineral wool and natural cork. It is recommended to use at frequencies not less than 20 Hz;

rubber shock absorbers (at frequencies of at least 12 Hz). Rubber has high elastic qualities, but these qualities are lost over time - rubber is aging. In addition, it is necessary to take into account a small change in the volume of rubber, therefore, if you install the unit on a thick piece of sheet rubber, then such an installation will differ little from a rigid one. Rubber gaskets must be shaped to allow free stretching of the rubber to the sides;

metal-rubber shock absorbers - represent a combination of steel springs with rubber. Applied at frequencies of at least 6 Hz;

spring dampers are used at any vibration frequency.

Application of dynamic vibration dampers. An additional oscillatory system is installed with a frequency equal to the frequency of the disturbing force. This system causes equal but antiphase oscillations.

Balancing, balancing.

Rigid connection of the unit to the foundation of a large mass. The vibration amplitude of the base of the foundation should not exceed 0.1 ... 0.2 mm, and for particularly critical installations - 0.005 mm.

The use of personal protective equipment. As personal protective equipment, gloves with a pad on the palmar surface and shoes with thick soft soles are used (GOST 12.4.002–84 "Personal protective equipment for hands from vibration"; GOST 12.4.024–86 "Special vibration-resistant footwear").

To effectively protect workers from noise and vibration, it is necessary to introduce complex measures of an engineering, technological, organizational and medical nature. This should include the reduction of noise and vibration at the source of their formation, isolation of noise and vibration sources using sound and vibration protection and sound and vibration absorption, the introduction of architectural and planning solutions with the rational placement of technological equipment, machines and mechanisms, the use of personal protective equipment. preventive health measures.

Reducing noise and vibration at their sources is the main and most rational method of protecting workers. This should be taken into account at the design stage, as well as during the operation of technological equipment.

As a rule, to reduce noise, the source is enclosed in an insulated room or the noise level generated by its own sources (technological equipment) is reduced.

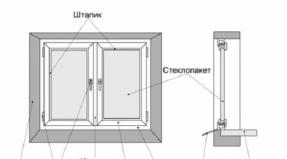

To reduce the noise coming into the insulated room, they improve the sound insulation of ceilings, walls, doors and windows. For example, under the action of low- and medium-frequency noise, the sound insulation of windows can be improved by installing air gaps (up to 100-150 mm thick) between the sashes.

To reduce noise in a room with its own sources, work places are designed to be isolated from the noisiest equipment. For this purpose, the equipment is placed in boxes, provides for the installation of sound-insulating casings above it, and screens, baffles and sound-absorbing partitions are placed on the path of propagation of sound waves. Separate low-noise rooms from rooms with intense sources of noise. For example, it is not allowed to locate laboratories and design offices in the immediate vicinity of gas turbine plants.

Sound insulation in industrial buildings. Sound insulation is understood as the creation of special building devices - barriers - walls, partitions, casings, ceilings, etc., preventing the propagation of noise. Most often, concrete, brick and ceramic blocks are used for the manufacture of soundproof structures.

To protect the maintenance personnel from noise, observation and remote control cabins are arranged. Cabin structures must provide the required sound insulation. They are made of lightweight materials, well sealed, and from the inside they are treated with sound-absorbing materials (Figure 11.3).

A simple and inexpensive way to reduce noise from the noisiest units is to install soundproof enclosures above them. The use of housings makes it possible to reduce noise in the workplace to almost any required value. The casings can be removable or collapsible, have viewing windows, openings for entering communications (Fig, 11.4). Sound insulation is improved by applying a layer of sound-absorbing material to the inner surface of the casing walls. Soundproof enclosures are best placed on the floor on

Rice. 11.3. Soundproof cabins:

1 - ventilation muffler; 2 - exhaust fan; 3 - sheet of steel or aluminum alloy; 4 - plexiglass; 5 - rubber gasket; b - a shell made of a perforated air floor; 7 - sound absorbing material [†]

A

Rice. 11.4. Sound absorbing casing:

rubber gaskets, avoiding contact of the casing elements with the unit.

Sound absorption in industrial premises. To reduce noise in industrial premises, along with sound insulation, sound absorption methods are used. When sound waves hit sound-absorbing materials and structures, a significant part of the sound energy is absorbed and converted into other types of energy, mainly heat. Ultra-thin basalt fiber, fiberglass, mineral wool, porous vinyl chloride, acoustic plaster and felt are used as sound-absorbing materials. Sound-absorbing structures include sound-absorbing linings, piece absorbers, chamber silencers. It is advisable to make sound-absorbing facings and install piece absorbers only if there are a large number of high-efficiency noise sources in industrial premises.

Piece sound absorbers are volumetric structures made in the form of prisms, cubes, balls and other figures and suspended indoors. They are made from perforated sheets of metal, foil, plastics and plywood, and from the inside they are pasted over with a cloth or filled with sound-absorbing material. The greatest acoustic efficiency of piece absorbers is achieved when they are placed in the immediate vicinity of a noise source or in places where sound energy is concentrated (Fig. 1] 5).

Sound absorbing facings reduce noise by 6-8 dB in total in the reflected sound area, making the noise less annoying. For their manufacture, mineral wool silane plates are used. In rooms with a large area, honeycomb ceiling structures are arranged. The honeycomb material is silane plates and gypsum.

Acoustic screens are used to protect working people from direct exposure to noise. They are made

solid solid metal or plastic sheets or shields. The side facing the noise source is treated with a 50 - 60 mm thick layer of sound absorber. The linear dimensions of the screen should be 2 - 3 times larger than the dimensions of the noise source. Thanks to the installation of acoustic screens, noise in workplaces is reduced at medium frequencies by up to 10 dB, at high frequencies by up to 15 dB. With sound-absorbing linings, the acoustic performance of the screens increases.

Reducing the noise of ventilation and gas-dynamic installations is achieved mainly by soundproofing the source or by using mufflers that are installed on air ducts, suction ducts, exhaust and air bypass lines.

Vibration protection methods. The main methods for reducing vibration are vibration isolation, vibration absorption and vibration damping.

To create vibration isolation, shaking equipment is installed on vibration isolators, which attenuate the vibration of the machine relative to the supporting structure. As vibration isolators, gaskets made of elastic materials, spring, rubber-metal and other shock absorbers are used. Elastic gaskets (rubber and cork) are used to eliminate high-frequency vibrations. The disadvantage of rubber vibration isolators is their fragility - they serve no more than 15 years.

Steel vibration isolators effectively reduce low-frequency vibration, they are more durable and more reliable than rubber ones.

With the help of vibration absorption, they reduce vibrations that propagate along the thin-walled metal structures of machines and air ducts. For this, vibration-absorbing (vibration-damping) coatings made of materials with high internal friction are applied to the surface of thin-walled structures, which makes it possible to increase the loss of vibrational energy in the system due to its transition to thermal energy. Vibration-absorbing coatings are made of rubber, plastic, asbokarpsh or felt impregnated with bitumen. The thickness of the vibration-absorbing coating should be 2 - 3 times greater than the thickness of the structure to be coated.

With the help of vibration damping, mechanical vibrations of structures are weakened. This is done by introducing additional stiffness elements into the oscillatory system. It is also possible to introduce an additional oscillatory system that attenuates the oscillation frequency of the main system. In domestic practice, low-frequency vibration dampers are used for this purpose. To measure noise and vibration, sound level meters (VShM-201), noise and vibration meters (VShV-003-M2) and sound level meters-vibrometers (SHVD 001 and ShVI) are used.

Noises and vibrations, as well as electromagnetic fields and radiation, ionizing radiation and the effects of radionuclides, refer to the energy pollution of the technosphere. Both noise and vibration have an adverse effect on the human body and general well-being, but it is manifested differently... Noises mainly affect the hearing organs, causing hearing loss, and can also cause pathological changes in the cardiovascular system with prolonged exposure, weaken the response and attention of a person.

Noise- This is a combination of sounds of different frequency and intensity that adversely affects a person, randomly changing in time.

Vibrations- these are mechanical vibrations of elastic bodies or vibrational movements of mechanical systems, transmitted to the human body or its individual parts.

Vibration mainly affects the internal organs of a person, causing vibration sickness. The main parameters of sound vibrations are sound pressure, sound intensity, frequency, sound waveform. The smallest value of sound pressure perceived by a person at a frequency of 1 kHz is 2 · 10 -5 Pa, called the threshold value.

The smallest value at which pain occurs is 20 Pa (120 dB in level). For most people, the pain threshold is 140 dB.

The most unfavorable for a person is noise lying in the region of average audible frequencies in the range of 1000 - 4000 Hz. The adverse effects of noise depend on the acoustic level (sound pressure level or sound intensity), frequency range, and uniformity of exposure during working hours.

Sound pressure Is the difference between the instantaneous pressure value at a given point of the medium when sound waves pass through it and atmospheric pressure in the absence of sound waves.

The sound pressure level can be determined using the formula:

where is the root-mean-square value of the sound pressure at the point of measurement, Pa;

- zero (threshold) value, Pa.

Noise fluctuations have the property of accumulation in the body (cumulativeness).

The harmfulness of noise as a factor in the working environment leads to the need to limit its level. To prevent and reduce the harmful effects of noise, hygiene standards must be observed.

These standards are based on the limitations of the sound pressure level within the octave bands of the entire noise spectrum, taking into account the nature of the noise and the characteristics of work.

The frequency range from 16 Hz to 20 kHz is called audible. Frequency range below 16 Hz - infrasonic, above 20 kHz - ultrasonic.

Despite the fact that both infrasounds and ultrasounds are not audible, their levels are also normalized, because have an adverse effect on humans.

Sources of noise in an urban environment are vehicles and industrial equipment, infrasound - impact technological equipment, rail transport and pneumatic tools, ultrasound - rocket engines and wind-blown water surfaces and construction sites.

The main parameters of vibration are: frequency and amplitude of vibration that cause vibrations of the human body when vibration propagates through the tissues of the body, vibration velocity and vibration acceleration.

Vibration is general and local. General subdivided into transport, technological, transport and technological. Sanitary standards establish the maximum permissible vibration values.

Personal protective equipment is headphones, earplugs, etc.

The most effective are means that reduce noise and vibration levels at the source itself, but this is not always achievable.

Noise and its effect on the body. It was found that the human hearing organ perceives the difference in sound pressure change in the form of a multiplicity of this change, therefore, to measure the noise intensity, a logarithmic scale in decibels is used relative to the hearing threshold (minimum sound pressure perceived by the hearing organ) of a person with normal hearing. This value, equal to 2 · 10 -5 Newton per 1 m 2, is taken as 1 decibel (dB).

With an increase in the sound intensity, the pressure created in the sound wave by eardrum at a certain level, it can cause pain. This sound intensity is called the pain threshold and is within 130 dB.

In production conditions, as a rule, there are noises of varying intensity and spectrum, which are created as a result of the operation of various mechanisms, units and other devices. They are formed due to rapid rotational movements, sliding (friction), single or repeated shocks, vibration of tools and individual machine parts, turbulence of strong air or gas streams, etc. Noise has different frequencies in its composition, and yet each noise can be characterized the predominance of certain frequencies. It is conventionally accepted to divide the entire spectrum of noise into:

Low-frequency - with an oscillation frequency of up to 350 Hz,

Medium frequency - from 350 to 800 Hz

And high-frequency - over 800 Hz.

Low-frequency noise includes noises of low-speed non-impact units, noises penetrating through sound-insulating barriers (walls, ceilings, casings), etc .; medium-frequency noise includes the noise of most machines, units, machine tools and other moving devices of non-impact action; high-frequency ones include hissing, whistling, ringing noises characteristic of machines and units operating at high speeds, shock action that create strong flows of air or gases, etc.

Occupational noise of varying intensity and spectrum (frequency), long-term exposure to workers, can eventually lead to a decrease in hearing acuity in the latter, and sometimes to the development of occupational deafness. This adverse effect of noise is associated with prolonged and excessive irritation of the nerve endings. auditory nerve in inner ear, as a result of which overwork occurs in them, and then partial destruction. Studies have found that the higher the frequency composition of the noises, the more intense and longer they are, the faster and stronger they have an adverse effect on the hearing organ.

In addition to local action- on the organ of hearing, noise also has a general effect on the body of workers. Noise is an external stimulus that is perceived and analyzed by the cerebral cortex, as a result of which, with intense and long-acting noise, an overstrain of the central nervous system occurs, spreading not only to specific auditory centers, but also to other parts of the brain. As a result, the coordinating activity of the central nervous system is disrupted, which, in turn, leads to a disorder of the functions of internal organs and systems. For example, workers who have been exposed to intense noise for a long time, especially high-frequency noise, complain of headaches, dizziness, tinnitus, and medical examinations reveal peptic ulcer, hypertension, gastritis and other chronic diseases.

The effect of vibration on the body. The perception of vibration depends on the frequency of vibrations, their strength and range - amplitude. Vibration frequency, like sound frequency, is measured in hertz, energy - in kilogram meters, and vibration amplitude - in millimeters. In recent years, it has been established that vibration, like noise, acts on the human body energetically, therefore, it began to be characterized by a spectrum in terms of vibrational speed, measured in centimeters per second or. like noise, in decibels; the threshold value of vibration is conventionally taken as a speed of 5 · 10 -6 cm / sec. Vibration is perceived (felt) only when it comes into direct contact with a vibrating body or through other solid bodies in contact with it. When in contact with a source of vibrations that generates (emitting) sounds of the lowest frequencies (bass), along with the sound, shock is also perceived, that is, vibration.

Depending on which parts of the human body are subject to mechanical vibrations, local and general vibrations are distinguished. With local vibration, only that part of the body that is in direct contact with the vibrating surface, most often the hands, is subjected to shock (when working with hand-held vibrating tools or when holding a vibrating object, machine part, etc.). Sometimes local vibration is transmitted to parts of the body that are articulated with the directly vibrated joints. However, the amplitude of vibrations of these parts of the body is usually lower, since as the vibrations are transmitted through the tissues, and so. softer, they gradually fade. General vibration spreads to the whole body and occurs, as a rule, from the vibration of the surface on which the worker is located (floor, seat, vibration platform, etc.).

Vibrations transmitted from a vibrating surface to the human body irritate numerous nerve endings in the walls. blood vessels, muscle and other tissues. The response impulses lead to disturbances in the usual functional state some internal organs and systems, and primarily peripheral nerves and blood vessels, causing their contraction. The nerve endings themselves, especially the skin ones, also undergo changes - they become less susceptible to irritation. All this manifests itself in the form of unreasonable pain in the hands, especially at night, numbness, a feeling of "creeping", sudden whitening of the fingers, a decrease in all types of skin sensitivity (pain, temperature, tactile). This whole complex of symptoms characteristic of vibration exposure is called vibration disease. Patients with vibration sickness usually complain of muscle weakness and fatigue. In addition to this, in women from exposure to vibration, violations of the functional state of the genital area often appear.

The development of vibration disease, etc. other unfavorable phenomena depends mainly on the spectral composition of vibration: the higher the vibration frequency and the greater the amplitude and speed of vibrations, the greater the danger of vibration in relation to the timing and severity of vibration disease.

Cooling of the body, mainly of those parts that are subject to vibration, muscle tension, especially static, noise, and others, contribute to the development of vibration disease.

Measures to combat noise and vibration. First of all, it is necessary to pay attention to the technological process and equipment, if possible, replace operations accompanied by noise or vibration with others. In some cases, it is possible to replace the forging of metal by stamping, riveting and embossing - by pressing or electric welding, emery cleaning of metal - by fire, sawing with circular saws - by cutting with special scissors, etc. It is necessary to ensure that such a replacement does not create any additional harm which can have a more adverse effect on workers than noise and vibration.

Elimination or reduction of noise and vibration from rotating or moving components and assemblies is achieved, first of all, by precise fitting of all parts and debugging of their work (reduction to a minimum of tolerances between connecting parts, elimination of distortions, balancing, timely lubrication, etc.). Springs or damping material (rubber, felt, cork, soft plastics, etc.) should be placed under rotating or vibrating machines or individual units (between colliding parts).

It is not recommended to place rotating machine parts (wheels, gears, shafts, etc.) on one side of the machine: this complicates balancing and leads to vibration. Vibrating large surfaces that create noise (rattling), such as casings, covers, covers, walls of boilers and tanks when riveting or stripping them, etc., should be more tightly connected to fixed parts (bases), laid on shock-absorbing pads or covered with a similar material on top.

To prevent turbulence of air or gas flows that create high-frequency noises, it is necessary to carefully mount gas and air communications and devices, especially those under high pressure, avoiding roughness of internal surfaces, protruding parts, sharp turns, leaks, etc. To release compressed air or gas should be used not simple taps, but special valves.

An important role in the fight against noise and vibration is played by architectural and construction and planning solutions in the design and construction of industrial buildings. First of all, it is necessary to remove the most noisy and vibrating equipment outside the production premises where the workers are located; if this equipment requires constant or frequent periodic monitoring, soundproof booths or rooms for service personnel are equipped at the site of its placement.

Rooms with noisy and vibrating equipment should be isolated as much as possible from other work areas. Similarly, it is advisable to isolate rooms or areas with noise of different intensity and spectrum. Walls and ceilings in noisy rooms are covered with sound-absorbing materials, acoustic plaster, soft draperies, perforated panels with slag wool lining, etc.

Powerful machines and other rotary or impact equipment are installed on the ground floor on a special foundation completely separated from the main building foundation, floor and supporting structures. Such equipment of lower power is installed on the supporting structures of the building with gaskets made of shock-absorbing materials or on consoles attached to the main walls. Equipment that generates noise is covered or enclosed in insulated cabins with sound-absorbing covers. Gas or air communications are also soundproofed through which noise can propagate (from compressors, pneumatic drives, fans, etc.).

As personal protective equipment when working in noisy rooms, various anti-noise (anti-phonics) are used. They are made either in the form of inserts made of soft sound-absorbing materials inserted into the external auditory canal, or in the form of headphones that are worn on the auricle.

When working in conditions of general vibration, a special vibration-damping (shock-absorbing) platform is placed under the worker's feet. When exposed to local vibration (more often on the hands), handles and others vibrate; vibrating parts of machines and tools (for example, a pneumatic hammer) in contact with the worker's body are covered with rubber. or other soft material. Gloves also play a vibration-damping role. Vibration control measures are provided not only when working directly with vibrating tools, machines or other equipment, but also when in contact with parts and tools that are subject to vibration from the main source.

It is necessary to organize the work process in such a way that operations accompanied by noise or vibration alternate with other work without these factors. If it is impossible to organize such an alternation, it is necessary to provide for periodic short breaks in work with the shutdown of noisy or vibrating equipment or the removal of workers to another room. Avoid significant physical activity, especially static stress, as well as cooling of the hands and the whole body; during breaks, be sure to do physical exercises (physical training pauses).

When hiring a job associated with possible exposure to noise or vibration, mandatory preliminary medical examinations are carried out, and in the process of work - periodic medical examinations once a year.

Ultrasound and its effect on the body, preventive measures. In industrial conditions, to obtain ultrasound, installations are used, consisting of high-frequency alternating current generators and a magnetic transducer.

Ultrasound is capable of propagating in all media: in gaseous, including air, liquid and solid. When ultrasound is used for industrial purposes, the vibrations created by its source are most often transmitted through a liquid medium (when cleaning, degreasing, etc.) or through a solid medium (when drilling, cutting, grinding, etc.). However, in both cases, some part of the energy generated. a source of ultrasound, passes into the air, in which ultrasonic vibrations also occur.

Ultrasound is evaluated according to its two main parameters:

Oscillation frequency

And the sound pressure level.

Oscillation frequency, like noise and vibration, is measured in hertz or kilohertz (1 kHz equals 1000 Hz). The intensity of ultrasound propagated in air and gas, as well as noise, is measured in decibels.

The intensity of ultrasound propagated through a liquid or solid medium is usually expressed in units of the power emitted by a magnetostrictive transducer per unit of irradiated surface - watts per square centimeter (W / cm 2).

Ultrasonic vibrations directly at the source of their formation propagate directionally, but already at a short distance from the source (25 - 50 cm), these vibrations transform into concentric waves, filling the entire working room with ultrasound and high-frequency noise.

When working on ultrasonic installations of significant capacities, workers complain of headaches, which, as a rule, disappear at the end of the work; unpleasant noise and squeaking in the ears (sometimes up to painful sensations), which are saved even after the end of work; rapid fatigue, sleep disturbance (more often daytime sleepiness), sometimes weakening of vision and a feeling of pressure on eyeball, poor appetite, dry mouth and stiffness of the tongue, abdominal pain, etc. When examining these workers, they reveal some physiological changes during work, expressed in a slight increase in body temperature (by 0.5 - 1.0 o C) and skin (by 1.0 - 3.0 o C), a decrease in the pulse rate (by 5 - 10 beats per minute), a decrease in blood pressure - hypotension (the maximum pressure is up to 85 - 80 mm Hg, and the minimum is up to 55 - 50 mm Hg), somewhat slowed down reflexes, etc. clinical manifestations: emaciation (weight loss up to 5-8 kg), persistent appetite disorder (aversion to food up to nausea or insatiable hunger), impaired thermoregulation, dullness of the skin sensitivity of the hands, decreased hearing and vision, dysfunction of the endocrine glands, etc. All these manifestations should be regarded as a result of the combined action of ultrasound and the accompanying high-frequency noise. At the same time, contact irradiation with ultrasound causes faster and more pronounced changes in the body of workers than exposure through the air. With an increase in the experience of working with ultrasound, the phenomena of its adverse effects on the body also increase. Individuals with work experience in these conditions up to 2 - 3 years usually rarely reveal any pathological changes even with intense doses of ultrasound exposure. In addition, the degree of adverse effects of ultrasound depends on its intensity and duration of exposure, both one-time and total per work shift.

Prevention of the adverse effect of ultrasound and the accompanying noise on the body of workers should first of all be reduced to a minimum of the intensity of ultrasonic radiation and the duration of action. Therefore, when choosing an ultrasound source for a particular technological operation, one should not use powers that exceed those required for their implementation; they need to be turned on only for the period of time that is required to perform this operation.

Ultrasound installations and their individual units (high-frequency current generators, magnetostrictive converters, baths) should be soundproofed as much as possible by enclosing them in shelters, isolation in separate cabins or rooms, covering with soundproof material, etc. If complete sound insulation is impossible, partial insulation is used, and also sound absorbing screens and coverings.

The most common personal protective equipment when working with ultrasound are ear muffs and gloves. It is advisable to have the latter two-layer: rubber on the outside, and cotton or woolen on the inside, they absorb vibrations better and are waterproof.

If the initial signs of an adverse effect of ultrasound on the body of workers are identified, it is necessary to temporarily stop working in contact with ultrasound (another vacation, transfer to another job), which leads to the rapid disappearance of the symptoms of exposure.

All newcomers to work with ultrasound are subject to mandatory preliminary medical examination, and in the future - periodic medical examinations at least once a year.