Toilet cistern repair - malfunctions and their elimination. The most common breakdowns of the toilet cistern and how to fix them The toilet cistern does not work what to do

A functioning bathroom is what is required for a comfortable stay in a house or apartment.

It is extremely frustrating when the toilet breaks. If the water is constantly leaking, it is also expensive. Payment for water is by meter.

It is not always possible to replace a product.

In the case of a mechanical control system, the toilet cistern can be repaired independently. Before troubleshooting, you should decide on the type of drain and identify the cause of the breakdown.

Kinds

drain cisterns

The devices differ in several design details.

Drain mechanisms

- Lever. It is installed in separate products, where the tank can be located both above and below. Water is drained into the toilet bowl when the lever is actuated.

- Pneumatic. Water is drained after pressing the button of the pneumatic chamber.

- stock. The rod rises, the mechanism frees the passage for the liquid. The stem is always displayed on the tank cover.

- Button. The drain mechanism works by pressing a button, which is located on the tank lid. Models with two flush buttons are available. When one button is pressed, half of the liquid descends, when another button is pressed, the entire drive is drained.

The reservoir is filled with liquid until right level, after the water supply is automatically stopped.

valves

The type of valve depends on how the water is supplied to the tank.

Systems without a float are lower and side.

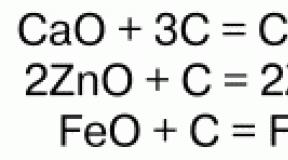

Such structures are equipped with a special camera. The system works according to the law of Archimedes. The tank is filled with water and the location of the chamber is changed, which stops the flow of liquid.

The side valve with a float is manufactured in two versions - diaphragm and piston. In each option, filling the tank stops when a certain amount of water is collected.

The drain mechanism may consist of interchangeable parts or be a single set.

Connection type

- Side. The tank has two openings on each side. A flexible hose is brought to one of the walls, a plug is placed on the second hole. The disadvantages of such an eyeliner are excessive noise when collecting water and the lack of aesthetics.

- Bottom type of eyeliner. The hose for a set of liquid is mounted in the bottom of the tank. Filling is almost silent.

One model can be produced with two types of connection. Three mechanisms that are present in each tank.

- shut-off or drain mechanism. Regulates drain, controls overflow.

- Bulk valve. The valve for filling the tank can be located both on the side and below. The float is always on top.

- Drain device and overflow.

The main breakdowns of the toilet tank are always associated with these three devices.

For your information. Mechanical damage to the tank itself (cracks or chips) cannot be repaired. The product will need to be replaced.

Drain tank malfunctions

Water from the tank flows to the floor

If dampness or a puddle of clean water appears behind the toilet bowl, this indicates that the gasket installed between the tank and the toilet bowl has become unusable and must be replaced.

To make a replacement, you will first need to purchase an o-ring. Then follow the instructions to fix the problem.

- Shut off the water supply to the toilet.

- Drain water from tank

- Disconnect the water supply hose

- Release the tank from the lid

- Dismantle the drain tank

- Replace gasket

- Reassemble in reverse order.

Waterproof silicone can be used to increase sealing.

No water is delivered to the tank

This error has several causes.

As soon as the water began to flow freely, we set the valve, the valve with the lever and the float to its original position. Sometimes cleaning the valve fails, in which case it should be replaced.

Water constantly leaks into the bowl

- The reason is the incorrect operation of the float. It does not stop the flow of liquid, and it constantly flows through the overflow.

- Lever changed position to inoperable

- Broken water supply valve

If the design of the tank of the Soviet era, you should start to identify the malfunction from the float. Perhaps it burst, water flowed into it and it can no longer rise and stop the water supply. If this is the reason, the part must be replaced.

In modern toilets, a drain column is installed, there is no float in them. This part is not repairable, just replaced with a new one.

Water may leak due to a broken inlet valve.

- Check the lever next to the valve for mechanical damage.

- We release the tank, we look at how water is collected

- Move the lever. He closes the valve. If there is a bend, straighten the lever.

- The lever does not move. A jam has occurred. We are replacing the node.

A failure of the inlet valve itself implies its replacement. The part is dismantled, a similar one is bought in the store and installed in the system.

Broken internal fittings

Sometimes there are several faults at the same time. The entire drain system should be replaced.

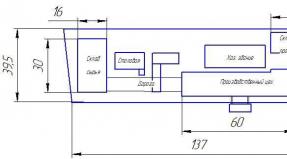

Replacing the drain mechanism with a lower set of water.

- Close the tap to supply water to the tank, free it from the liquid.

- We remove the cover.

- Unscrew the flexible hose

- Turn the top of the column and remove

- We dismantle the tank by first unscrewing the retaining bolts

- Dismantle the inlet valve and drain button

- We take out the old mechanism

- Installing new fittings.

- We put the tank in its original position.

Loud noise when filling water

This fact is not a defect. Noisy tanks with a top supply.

Models are available where you can adjust the diameter of the hole. It won't completely eliminate noise, but it will reduce its level.

In cases where it is not possible to make adjustments, there is a modification option.

A rubber tube with an inlet diameter up to 30 cm long is taken.

The tube is put on the inlet, fixed, the end is lowered to the bottom of the tank.

This eliminates the fall of water from a height, filling starts from the bottom, respectively, the noise disappears.

Sticky button or two buttons

The toilet model with two flush buttons is in demand. In such a product, sticking of buttons sometimes occurs. To make repairs, you need to remove the cover.

First, the nuts holding the buttons are unscrewed, after which you can open the tank. Pressing the buttons at the same time sometimes helps them fall into place.

If the manipulation did not work, you should check the button shaft. Sometimes she gets dirty. After cleaning the shaft, repeat the check. If there is no result, a new part must be installed.

The node is dismantled, purchased exactly the same and installed.

Results

In the event of a malfunction, it is far from always necessary to buy a new product; it is often very easy to repair it yourself.

Anton Tsugunov

Reading time: 4 minutes

Plumbing equipment is subject to intensive operational loads and often fails. When the toilet cistern constantly flows, it brings great losses due to water overruns. It is not advisable to call the masters due to the failure of the device, since the repair mostly consists in setting up the tank mechanism. But in order to understand how to fix a toilet, you first need to know how it works. Let's figure out how to independently repair the toilet flush tank with a button.

Toilet device

The composition of the toilet includes the following elements:

- A toilet bowl connected to a sewer pipe with an airtight cuff.

- Drain tank with fittings that ensure its filling with water and draining.

A water supply hose is connected to the tank. Depending on the design, it is connected from the side or from below. The bowl and tank are usually connected to each other with bolts and a seal.

Hardware components:

- pull-rod trigger with drain button;

- a shut-off device (inlet valve) connected to the float;

- rubber seals.

The principle of operation of the toilet with a button

The toilet cistern with a button is a water seal filled with a portion of water that is fed into the bowl when the shutter is opened. Flushing is controlled by a button that must be pressed. This opens the valve, and the water under its own weight flows down, washing the bowl. After the tank is released, the shut-off valve at the inlet opens, the container is filled with the next portion to a certain level, regulated by a float. Access to the mechanism is provided by opening the top cover of the tank.

Preparation for repair

Before you fix the toilet cistern, it must be opened. It can only be accessed from above by removing the cover. In many modifications, it is attached with a ring around the button. This ring must be pressed and turned counterclockwise. After a long period of use, the ring may not turn. Then a few drops of oil are applied to the attachment site. After the ring turns, it is unscrewed, and then the button is released from the plastic clothespins and the cover is removed.

Do-it-yourself ways to repair the tank mechanism

Through the upper hole in the tank, the entire mechanism of the drain valve is visible. It may have the following faults:

- The tank is constantly leaking.

- There is no water pressure at the inlet.

- Uncontrolled drain mechanism.

The causes of these malfunctions can be different, and the way in which the toilet cistern will be repaired depends on them.

- The plug (pear) does not fit snugly against the drain hole. To avoid this, you should purchase high quality plumbing. The possibility of repair can be checked by pressing the stem with a little force. If at the same time the water does not flow, the cork can be slightly weighted with an additional load or the rod can be leveled. You also need to periodically clean the seal from rust and salts, due to which the tightness is broken, and the liquid constantly flows into the bowl.

- The regulator does not shut off the water supply. At the same time, the tank will never overflow, thanks to the presence of an overflow tube. The serviceability of each element of the device is checked: float, inlet valve, fasteners, rod. The failed part is replaced or the float mount is simply tightened.

- Leak from the tank into the room. It may have a crack or the tightness of the gaskets is broken. Particular attention should be paid to the quality of the connection between the current tank and the bowl. It needs to be tightened, and if this does not help, the rubber gasket changes. Another cause of leakage may be the wear of the cuff in the joint between the bowl drain and the sewer pipe. The seal is changed to a new one, having cleaned the connection of contaminants and treating the surfaces with a sealant.

- Weak pressure through the intake valve. This usually happens if it becomes clogged. You can prevent this by cleaning or installing a filter in front of it.

Inlet valve replacement

Before repairing the toilet, turn off the water supply tap. It connects to the pipeline from the riser. After that, the flexible hose is unscrewed from the intake mechanism. It can be easily removed by loosening the fastener. Instead, a new or refurbished one is installed. Assembly is carried out in reverse order. A plastic thread does not require sealing, and a fluoroplastic tape is wound onto a brass thread.

Bleed valve replacement

The main reason is the wear of the sealing ring under the valve. To replace it, you need to remove the hardware and install a new gasket. After the assembly is carried out in the reverse order.

The water release button should always be used carefully and pressed without sudden force.

Adjusting the water level in the tank

The water level can be easily adjusted by hand. To do this, the float is set in a certain position.

The optimal level is considered to be when the water supply to the container has stopped, and a few centimeters remain to its upper edge.

The method of adjustment depends on the design of the valve. The simplest is bending a metal bar. If the float moves along a horizontal plastic guide, it is fixed with the help of fastening elements in a certain position. With a vertical layout, it is moved with an adjusting screw.

When choosing the fill level, do not forget about the overflow pipe. Its upper edge should be a couple of centimeters above the water level in the filled container. If it is located lower, water will constantly flow through the overflow into the bowl.

Tank Troubleshooting

The tank may leak water due to a crack that has appeared in it. The same applies to the bowl. In this case, the question of how to repair a cistern or bowl is not worth it: the entire toilet is usually changed. A small crack in upper parts ceramic products can be sealed. So that it does not spread further, and the seepage of water does not increase, it is drilled at the ends and processed along the entire length with sandpaper. The work is done neatly.

The surface is degreased, and the gap is filled with epoxy. After hardening, the seam is polished.

Built-in cistern repair (with installation)

It is more difficult to get to the mechanism of a tank installed behind a false wall. First of all, you should purchase a device with high reliability, which rarely requires repair. There should be inspection hatches in the wall through which you can get to the tank and replace the gaskets if the tightness is broken. Do-it-yourself drain fittings cannot be repaired due to the complexity of the design.

A coarse filter is installed in front of the hidden tank, which traps solid particles, which in most cases cause leakage.

How to choose the right plumbing?

When choosing a toilet, pay attention to the following.

- Way of fastening: monoblocks, compact and separate toilet bowls. The choice is made taking into account the size of the room, the design and the complexity of maintaining the tank.

- Accessories. Most of the parts with low strength and reliability are made of plastic.

- The presence of positive reviews, a well-known manufacturer, the availability of a guarantee and a certificate.

Any leak in a plumbing fixture or in-house communications is a problem associated with financial losses, so it must be addressed immediately. If the toilet is leaking after flushing or the sound of a babbling stream is periodically heard from the toilet, it's time to check the condition of the tank. Do you agree?

We will tell you about the most common breakdowns that occur with plumbing equipment that is mandatory for equipped housing. Here you will learn how you can deal with them on your own. Taking into account our advice, you can eliminate such situations and competently repair an important device for life.

The flush function involves a long or short-term flow of water into the toilet bowl in order to cleanse it of waste products. The process begins with pressing the button built into the tank, and ends arbitrarily or by a second press.

Instead of a button, there may be a lever or a handle on a chain, like retro models, but such options are extremely rare.

By pressing the button we control . It is associated with a locking mechanism, which, after draining, opens the way for a new portion of water to enter from the cold water system. Thus, flushing occurs only at the request of the user.

If water flows into the toilet after flushing or, even worse, constantly flows in a thin stream, it's time to check the cistern fittings - one of the parts is out of order.

There are two ways to solve the problem: on your own, trying to figure out the structure of the trigger mechanism, or with the help of qualified plumbers

But first you need to determine that the leak is really present.

Signs of improper drain operation are the following factors:

- constant or intermittent characteristic sound of murmuring water;

- rusty and limestone stains at the point of water outlet;

- constantly wet inner wall of the toilet, close to the tank, even if the toilet has not been used for a long time;

- an unusually long and weak flushing process - a volley discharge is considered the norm;

- the appearance of condensate on the pipes and tank, which never happened.

The last sign is associated with constant movement cold water through a pipe, while under normal conditions, water is used periodically and before the moment of descent it has time to heat up to room temperature.

If you notice a rusty track or yellowish, hard-to-wash spots in the water outlet area, you should not stop at one cleaning - you must definitely revise the tank

Sometimes the cause of leaks lies in the dirt that has accumulated at the bottom of the water tank. In this case, it is enough to apply a thorough cleaning of the internal surfaces of the tank. To do this, they drain and shut off the water, carefully remove the fittings and use a brush and cleaning products to remove the sediment accumulated on the bottom and walls.

If operational cleaning does not help, you will have to get acquainted with the design of the drain mechanism.

We disassemble the tank device

There are several common reinforcement designs that can be called typical. Among them is an outdated type of drain device with a rubber pear, assembled according to the simplest scheme and suitable for tanks with a side connection.

This is a rare occurrence, uncharacteristic of modern models. Let us turn to the actual type of fittings, consisting of two modules: drain and float.

The float on a thick metal wire was improved and turned into a more complex structure, blocking the water supply not from the side, as before, but from below, although side models are occasionally found. The position of the float from them is adjustable, so you can dose the portion of the discharged water.

Reinforcement scheme. The drain is triggered by the movement of a button that is connected to the trigger mechanism. When the water leaves the tank, the inlet valve opens until the desired volume is reached

Due to the similarity of valve models, it is easy to replace the entire structure or change individual parts: is it a drain float mechanism, a drain lever.

To understand how each element is arranged separately, you can disassemble the model installed in the tank. Of course, before that, you need to take safety measures: shut off the water supply to the riser or the water supply and empty the tank.

All parts are unscrewed manually or with a set of keys. There are almost no metal parts, instead of them only plastic elements have long been used. They are quite durable, do not deform when interacting with hard water, do not rust, and are well cleaned with household chemicals.

In addition to fixed parts that are attached with bolts and rubber or plastic seals, there are parts that can be adjusted - the so-called sliders. They can be recognized by small divisions and notches.

The sizes and colors of parts from different manufacturers may vary, but the principle of operation is exactly the same. Therefore, if the seal is worn out and a trickle of water constantly leaks from the tank into the toilet bowl, it is not difficult to find a replacement.

To be sure, you can measure the diameter of the ring or simply present the old gasket to the seller.

Common Problems and Solutions

There are several reasons for a leak. Drainage problems can be caused by the failure of the drain column, clogged with dirt in the fittings, wear of rubber seals. Let's dwell on common cases of leaks and choose better ways problem solution.

Water is constantly flowing

One of the obvious signs indicating the need for urgent repairs is a thin trickle of water. If filters are not installed at the outlet of the main from the riser, over time the “channel” of the stream becomes covered with a sediment of rust and mineral deposits. If water is constantly flowing in the toilet - what should be done in such a situation?

Initially, the cause of the leak should be identified. It is clear that the point is not in the toilet bowl and not in installation errors - the roots of the trouble must be sought inside the tank. To begin with, we look under the cover and try to determine the breakdown visually. If this does not work, we dismantle in the following order.

Image gallery

The statistics are merciless: every Russian family has encountered breakdowns of the toilet cistern at least once. At the same time, in most cases, you can repair or eliminate the leak with your own hands in a couple of minutes.

This article will help you understand the device of this most important element in the house.

Content:

- Drain tank device;

- How to adjust the water level in the toilet tank;

- Major breakdowns and their repair;

- Constantly flowing water - correct the situation;

- Stop valve repair;

- Leak at the junction of the tank with the toilet.

The toilet bowl is a plumbing device that not a single city apartment (and most country houses) can do without.

It is used constantly, and therefore any malfunction, and even more so a breakdown, causes serious inconvenience. In most cases, you can set up and repair the toilet tank without the help of a specialist.

You just need to understand how it works, what the individual elements in the drain tank are responsible for - and then it immediately becomes clear what is the cause of possible problems.

Drain tank device

Roughly speaking, the toilet bowl consists of two parts - a bowl with a sewer hole and a tank for draining water.

It is in the cistern that the entire toilet mechanism is located, all the elements that drive it. By pressing a button or operating a lever, we make a simple mechanical system inside the tank work.

As a result, water enters the bowl, and all waste is washed down the drain.

Toilets come in different sizes and types of drains.

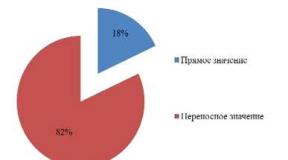

In some models, when you press a lever or button, the tank is completely emptied, splashing all the water down. In other tanks, there are two buttons: depending on the needs, you can drain more or less water. There are low-lying cisterns that are attached directly to the toilet, others are hung on the wall and connected to the bowl with a flush pipe, and others are mounted in the wall (this saves space in the restroom).

The drain system can also vary: some toilets supply water in a constant direction, in others, when draining, the water changes its direction.

The second option is considered more convenient and hygienic, although there is more noise from such a device.

Nevertheless, the internal arrangement of tanks of any type is approximately the same. And, having understood the principles of operation of one, if necessary, you can inspect and repair any other toilet tank.

The internal device of the drain tank consists of several elements:

- flush button;

- filling valve with float;

- drain fittings for the toilet bowl.

When you press the button in the drain tank, the valve opens, and the water is emptied into the bowl, flushing the contents of the toilet.

At the same time, the liquid level in the tank becomes lower - and the float reacts to this, falling down along with the water. Reacting to the "indications" of the float, the filling system is activated - and the water is again poured into the tank to the desired level.

The toilet cistern leaks quite often, this is mainly due to poor-quality fittings (insides), cracked seals and other minor troubles.

Water level in the tank: how to adjust?

One of the most frequent malfunctions in the work of the drain tank - this is a constant flow of water into the toilet.

This means that the water level is too high - the system has to constantly release excess liquid.

It also happens the other way around: the drain is inconvenient to use, because there is too little water in the tank all the time.

As a rule, the problem lies in the float - perhaps it is simply skewed.

In this case, the problem is solved quickly and easily - the float needs to be corrected.

The float in the drain tank is, as a rule, of two varieties: on a brass lever and on a plastic lever with a special screw. To adjust the float on the brass lever, you just need to carefully raise and lower it several times until it becomes clear in which position the mechanism will work optimally.

Raising the float raises the water level, lowering it lowers it.

As for the plastic lever, here the level is adjusted by turning the screw (or with a plastic ratchet, with which the lever is set to the correct position).

Repair of a drain tank: main breakdowns and their elimination

However, the malfunction of the drain system does not always depend on the position of the float.

Sometimes you have to understand the problem in more detail - but you can still carry out the simplest repair of the internal mechanism of the tank with your own hands.

There are the most common problems in the drain system:

- the tank leaks at the junction with the toilet bowl (does not hold water and is constantly filled);

- water is constantly flowing into the toilet from the tank.

As a rule, the causes of the problem are the following:

- float failure;

- breakage of the shut-off valve;

- poor sealing of pipes.

The toilet tank is leaking: what to do?

If water oozes into the toilet bowl from the tank all the time, first you need to make sure that the problem cannot be solved by simply adjusting the float.

If you tried to move and adjust the lever, it still does not hold water on the tank, then you need to inspect the float itself: it is likely that a hole has formed in it or a special membrane has become unusable.

The easiest thing to do when you find a hole in a float is to simply cover it up with a plastic "patch" or wrap the float in a bag.

Water will stop getting inside, and the problem will be exhausted for some time. However, at the first opportunity, it is better to replace the float - such a handicraft repair is unlikely to last long.

How to change the float?

- first of all, it is necessary to shut off the water entering the toilet tank, and then completely empty the tank;

- after that, the pipe is removed through which water entered the tank, and the damaged float is removed, and a new one is put in its place;

- the float is set in the desired position, after which you can put the pipe in place, start the water supply again and make sure that the problem is solved.

Stop valve repair

There are two ways to fix the breakdown of the locking device (toilet fittings) in the tank: replace only the membrane inside the mechanism or change the valve completely.

To change the membrane from the tank, it is also necessary to remove all the water from the tank, disassemble the shut-off valve, remove the protective cap and pull out the membrane itself.

Theoretically, it can be simply washed. However, experts recommend replacement, since the membrane is generally the “weak point” of the drain system, and others will surely follow the first malfunction.

If the shut-off valve needs to be replaced in its entirety, then the water supply to the toilet tank is also shut off to begin with.

After that, the liquid remaining in it is poured out of the tank, the lever is first disconnected from the mechanism, and then the valve itself is unscrewed from the water pipe, fixed with fixing nuts.

In its place, a new fitting for the tank is mounted, after which the water is turned on, the toilet tank is refilled and the float is set in the correct position.

The cistern is leaking at the junction with the toilet

If water oozes from the place where the tank connects to the toilet bowl, then most likely it is a poor seal.

As a rule, in this case, it is enough to tighten the bolts more tightly, with which the tank is attached to the toilet, or change the rubber gaskets - they may have dried out.

It happens that the gasket in the place where the tank is attached to the toilet comes across with a manufacturing defect. This is not very good news - however, you can simply smear it with a sealing compound, and the leak will be eliminated.

Condensation on the toilet bowl causes many problems - but you can get rid of it only by properly organizing the movement of air in the toilet, i.e.

check ventilation holes.

Summing up, we can say that the toilet tank is a simple device that works according to the simplest laws of mechanics. All malfunctions that occur in its operation are eliminated quickly and easily, and it is not even always necessary to buy new parts.

Thus, having understood the operation of your cistern, you can no longer waste money and time on plumbers, solving all problems on your own.

How a drain tank with a button works: principle of operation and device

Since the time of Ancient Rome, the presence of plumbing devices in the house was considered a sign of civilization. A special place was occupied by the sewerage system and the "latrine", which today successfully replaces the toilet with a convenient toilet bowl. We are so accustomed to comfort that the slightest change in the operation of the toilet bowl and its tank leads to confusion and excitement.

Therefore, when choosing a model for our home, we give it to the most reliable designs, which include toilet bowls with push-button flush cisterns.

Toilet cistern device with a button: design features

The cistern device with a button of all models has common features.

They differ only in the material of manufacture, price, quality and features of the working parts. The tanks operate according to the same principle, the differences are only in the mechanism, which can be:

- one-button;

- two-button;

- with a dual device.

The most modern model is a two-button system that saves water when flushing.

Pressing one button - a full flush, in which all the water contained in it flows out of the tank. Pressing two buttons - draining only part of the volume of water.

Models may also differ in flush features. In some, when descending into the toilet, the water comes directly from the cistern, moving in one direction.

In others, the flow of water is divided, flushing is carried out from different sides. Such tanks are considered the most efficient, as they cover the largest flush area, but are also noisier.

So that when buying this device, you need to have an idea of \u200b\u200bhow the toilet bowl flush tank with a button works, and know what its device consists of.

The mechanism of operation of any models is quite simple and consists in collecting a certain amount of water from the water supply and lowering it into the sewer through the toilet.

The principle of operation of a toilet flush tank with a button is a water seal system, which consists of a float, levers and seals.

Pressing the button on the lid activates the water release mechanism, which is the main purpose of this plumbing fixture.

The principle of operation of the drain mechanism

By pressing the button located on the lid, we force the tank system to start working.

The device of the toilet cistern with a button, the diagram of which is shown on picture below, is directly related to the filling of the container. Before starting work, the tank is in standby mode.

The tank already has the required volume of water, which is limited by the level of the float. Water in the tank is kept from flowing out by a special pear, which is made of elastic and durable rubber.

Do-it-yourself toilet cistern repair with a button

Pressing the button puts pressure on the lever-pull, which pushes the pear, thereby opening the drain.

When we release the button, the pear gradually begins to return to its place.

When assembling the internal filling of the sanitary device, this feature of the functioning of the pear should be taken into account. Its sharp return to its original position gives a short-term and incomplete drain. With proper assembly and adjustment, the process of lowering the pear is slow, it is completely hollow inside.

With the filling of the tank with water, the lifting force of this pear decreases, and at the end it takes its original position, sticking to the saddle.

Flush tank mechanism with button

The drain tank functions due to the operation of two systems: collecting water and draining it.

The first is called the inlet, and the mechanism of its action is quite simple. It lets water into the tank at the moment when there is no liquid in it. Filling goes up to a certain level, which is set by the reinforcement correction.

Armature may have different kind, but its principle of operation is the same - float. By adjusting the level of the float, you can adjust the degree of filling of the tank.

Outlet fittings, the purpose of which is to drain water, help to keep control over the drain process.

Its design during operation can take several positions. In some models, the outlet valve can operate in two modes: economy and standard.

In addition, the outlet valve mechanism has an emergency drain function, which can be used in case of emergency.

If some components of the outlet stop working in the desired mode, then you have to change the entire armature.

Problems in the operation of toilets mainly arise due to failures in the intake and exhaust systems. Therefore, in order to troubleshoot, you need to find out which of the systems has stopped working, either by replacing individual components or using a complete set.

The most common breakdowns

- Water enters the tank very slowly.

The problem is caused by a clogged membrane, the fix is to clean the inlet of debris and dirt. But for this it is necessary to carefully dismantle the reinforcement, and then also carefully return it to its original position.

- There is too much liquid in the tank, up to the overflow.

The reason lies in the incorrect setting of the float level. The solution to the problem is to adjust the float armature to such an extent that the float drops.

- The float arms are broken. The reason is the wear of the mechanism, such a malfunction cannot be repaired, so the solution is to replace the fittings.

Drain tanks with a button are the most common and easy-to-use plumbing fixtures. Knowing the device and the principle of operation of drain tanks will allow you to choose the most convenient and reliable models for your home.

How to fix a leaky toilet with a button on the cistern

If a broken tank lets water through, this causes not only inconvenience in the operation of the structure.

An additional cost item will be a large amount of leaking water. In more serious cases, such problems lead to a flood in the apartment.

Plumbing device

Before you fix a toilet that flows with a button, you need to deal with the entire device.

The design of a conventional household toilet bowl consists of a bowl and a flush tank. The last device can be attached to the toilet step, mounted separately on the wall or walled in on a special frame.

The drain tank works according to this principle:

- when the drain button is pressed, the shut-off valve rises;

- water receives a free flow into the cavity of the toilet bowl;

- through evenly distributed holes under the rim of the bowl, the water flow washes the entire cavity along the perimeter;

- when all the water has left the tank, another valve opens, letting in pressure from the cold water supply pipe to the apartment;

- The level of collected water in the tank is regulated by a float.

Under the lid of the tank there is an armature of the entire device: a float to control the level of collected water, seals and levers for supplying and cutting off the water flow.

A shut-off valve is responsible for supplying water.

It is attached to the way of connecting the hose for supplying water to the tank. The system of its work includes a float and a membrane.

Tanks with economical water consumption suggest the presence of two buttons in their device - for small and large drains. The mechanism of operation does not differ from standard tanks.

Preparing plumbing for repairs

At the first stage, the tap with the water supply to the tank is turned off.

Depending on the built-in taps, it is possible to deprive the entire apartment of water or block the flow only to the tank. If the water constipation mechanism is damaged, then there is a risk of organizing a flood in the apartment.

At the second stage, open the lid of the tank. Here you need to carefully consider the existing latches. If the structure is broken by force, then it will be difficult to find a similar cover (in plumbing stores they sell fully assembled kits, not individual components).

Before you start repairing a toilet bowl device that flows with a flush button, you need to prepare the necessary tools:

open-end wrenches of several sizes;

- screwdriver;

- pliers;

- tape with an adhesive backing for insulation.

Elimination of a permanent leak

Any model of the tank is equipped with a system that collects water and a trigger.

If the tank is not filled to the right level, water constantly flows into the bowl or even overflows over the top, then the problem lies in the systems for accumulating or draining water.

A possible problem lies in the pear, which does not fit snugly enough to the drain hole. In this case, a small load is hung on the pear.

Water does not enter the tank

This problem occurs when debris enters the narrow part of the valve device.

First you need to drain all the water from the tank. Completely remove the valve with lever and float.

Toilet cistern repair - malfunctions and their elimination

Then you can see the clogged hole. Through this passage, water is drawn into the reservoir. Garbage can be cleaned with a thin wire or a sewing needle.

On the inlet fitting, the valve is slightly unscrewed and the inside is washed with a stream of water. If, after removing the blockage, the water flows without obstacles, then you can screw the latch back and assemble the entire mechanism.

Troubleshooting a push-button cistern

The tank button is responsible for lowering the water into the bowl itself. After the draining process is completed, the float remains at the bottom of the device.

The stop valve also comes into this position, opening the hole for water to enter. As the water collects in the tank, the float rises.

Under this action, the lever begins to move.

Rising to the desired level, the lever and the float device take a certain position. In this case, the shut-off valve tightly covers the outlet of the nozzle and the water stops collecting.

If the toilet bowl with the drain button on the lid is leaking, then you need to do the following:

- Locate the retaining ring located around the drain button.

- Press the button all the way in and unscrew the plastic stopper.

- Remove the cover and start repairing.

The locking devices of the buttons are made of plastic.

Excessive mechanical impact on this element can lead to device failure.

Water can flow in a continuous stream and constantly flows from the installed tank to the toilet step with a button. In this case, you need to check the position of the float. To do this, open the tank lid and align the floating element.

Otherwise, water may constantly leak into the bowl due to an open hole in the drain pipe.

You can check the version by clicking on the pear. In the event of a jet stop, the cause has been clarified. They solve the problem by weighting the pear - by hanging an additional load.

In the event of a failure of the rubber bulb in the shut-off valve device, the tightness of the entire tank structure is violated.

The solution to the problem is to replace the damaged element. To do this, the float is brought to the upper position and fixed in this state. Unscrew the connecting nut from the container and remove the mechanism. Remove the worn pear from the valve and install a new one.

A new pear should be chosen as softly as possible.

In this case, the dimensions of the products must match.

Check the fixing bolts for the pear.

If they have become unusable, then you should purchase new ones and install them:

- water is completely removed from the tank;

- between the valve near the float and the liner there is a union nut that must be unscrewed and removed;

- the ear-shaped latches of the tank to the toilet shelf are unscrewed;

- slightly tilting the tank back, carefully remove the rubber connecting layer between the container and the installed toilet bowl;

- remove damaged bolts;

- the faience area under the pear is well cleaned of the formed plaque and dirt; the shelf and top of the tank are also washed out;

- if an old pear is installed back, then silicone must be applied to its surface for a tighter connection with the hole;

- all elements of the tank are installed in their place, and fixed with bolts;

- the connecting cuff is installed in its place;

- water is run into the tank several times in a row to fully check the result of the work.

If only one fixing bolt has become unusable, then you still need to buy both.

These elements must be the same in structure and length.

Overflow problem

If a water leak through the overflow hole is detected in the tank, and restoring the position of the lever does not help, then check the condition of the fixing pins. An unusable element can be replaced with a piece of copper wire. The thickness of the broken and new elements must match.

If the hole where the pin was placed is no longer round, then the valve will have to be changed.

It is important to purchase a completely identical new item.

Toilet flush column: varieties, tank equipment, types of mechanisms, installation instructions, malfunctions

It is impossible now to imagine any apartment or house without a bathroom. Soviet toilet models most often had metal components, they served for a long time and efficiently. In modern models, most parts are made of plastic. The drain column for the toilet bowl is an integral part of it.

Despite the simplicity of the device, it fails quite often.

If you study at least a little the device of the drain tank, then it will not be particularly difficult to install or repair it yourself.

Varieties of drain columns

The range of this equipment in plumbing stores is quite large.

To purchase a quality model that will serve you for a long time, you need to understand well and know how they differ from each other.

The very first thing that immediately catches your eye is the material from which the tanks are made, they are:

- Cast iron.

- Plastic.

- Faience.

Plastic drain column

Cast iron models are very reliable, but they cannot boast of their attractiveness.

Plastic speakers are very easy to install, but they also fail quickly. Most of all, faience cisterns are represented, they combine several qualities at once: reliability, ease of installation, a wide choice of shapes and even colors.

One drain column for the toilet is different from the other and the release valve. There are two of them:

If the trigger device is located at the top on the tank, then a special button is also provided.

Those columns that are attached at a certain height have a lateral location of the trigger. Everyone, probably, saw the attached rope or chain.

The trigger mechanism for both types is: mechanical and manual.

If the mechanism is manual, then you can always adjust the amount of water used.

Drain tank kit

Despite the wide variety of drain columns, there is no fundamental difference in the device, each must have:

- The valve responsible for the supply of water.

- Drain design.

- Overflow.

Drain column kit

The main function of the filling valve is to dose water into the column.

In most designs, the water level indicator is a float. In older models, this mechanism was made of brass, quite often they are made from it even now.

Technology does not stand still, so now the designs are different, but the general mechanism of work has not changed.

By the name itself, the purpose of the drain mechanism becomes clear. It can be implemented in different ways, whether it's pressing a button or pulling a string. Recently, tanks have become widespread, which have an economical drain, when, after pressing, not all the water is poured out, but only half of it.

An overflow must be mandatory to insure against accidental overflow of the tank. Usually it is combined with a drain mechanism.

Flush mechanism types

The drain mechanism of the tank can be of several varieties:

- Bell.

- Corrugation.

- Pear.

The first variety is considered the oldest and can currently be found in tanks that are mounted high and made of cast iron.

A chain or rope is attached to such tanks, we pull it and thereby raise the bell with a lever, which is represented by a cork with a gasket.

Draining

Through the drain, water passes into the pipe.

Then the bell is lowered, a discharged space is created, which sucks out the remaining water. Interestingly, such designs are very reliable, from time to time it is only necessary to change the gasket, and this can be done with your own hands.

A drain mechanism in the form of a corrugation can be found much less frequently.

The reason is that it has little strength, so it becomes unusable very quickly.

The last variety in the form of a pear was previously often located on the wall, but now such drain mechanisms have migrated along with the cisterns to the toilet itself. The mechanism of operation of such a device is quite clear: a rubber pear clogs the drain hole by itself until you move it from its place by pulling the rope.

Modern models have a radically changed mechanism in the form of a pear, but the principle of operation has practically remained the same.

Installation and appearance also changed significantly.

Drain column installation process

If we consider this process, then the installation of the tank consists of several stages:

Tank mounting methods

It turns out that the drain column can be installed in different ways. Installation instructions differ depending on the location of the tank.

The first option provides for the location of the tank almost under the ceiling.

It will connect to the toilet through a long pipe. Such designs are currently not very common, but they provide the maximum water pressure when draining.

The second way we see most often.

It is used in almost every apartment. In this case, the tank is on the toilet itself. The convenience of this location lies in the fact that everything is within direct reach. If necessary, you can easily dismantle or replace worn parts.

In the third option, the tank is built into the wall itself. This design has a significant drawback - if the tank breaks down, then you will have to practically disassemble the wall.

But there are no minuses without pluses, this will be especially noticeable if such a tank is in a combined bathroom. Due to the built-in, free space is freed up.

Drain tank breakage

If you open the cover of the drain column, you will be able to see everything that is the main thing in this whole structure.

When a breakdown occurs, it is this valve that fails.

A common problem that almost everyone encounters after a while of operation of the drain column is the flow of water into the tank without interruption. This can happen for several reasons:

- The float arm is a little warped. It will be enough to put the lever in horizontal position and everything will be back to normal.

- Float damaged.

There is nothing left but to change the float.

- The valve has failed. If repair is not possible, then you need to buy and install a new one.

Sometimes it happens that water constantly flows into the tank.

It can be concluded that the siphon membrane is damaged, and then it must be replaced in order to eliminate this problem.

If the levers become unusable, then it is almost impossible to repair them on your own, since most often they are made of plastic.

You just have to buy a new kit and install it.

If water leaks through the valve, then two reasons can cause such a nuisance:

- It is necessary to replace the rubber membrane, which has become unusable. It is necessary to remove the part on which the gasket is located, to do this, turn it counterclockwise.

- If a lot of debris accumulates under the valve, then this will also cause shortcomings in the work.

During the repair work, it is necessary to turn off the water so that it does not interfere with the repair of the breakdown.

After all repair procedures are completed, you need to make sure that the overflow device is installed correctly.

Toilet cistern button: principle of operation, replacement, repair

In tanks with a side-mounted shut-off valve, for convenience, it is possible to mount it on both sides. There are two holes in the tank: one is free, and the locking mechanism is inserted into the other. If it becomes unusable, then the water will begin to flow directly onto the floor.

Drain columns with top water supply are distinguished by strong noise during the process of filling the tank.

But this problem can also be overcome. To do this, you can put a piece of rubber tube on the branch pipe of the shut-off valve so that it reaches the very bottom. If there is a little time, desire, skills, then it is possible to ensure the efficient and uninterrupted functioning of the bathroom on your own.

For the normal functioning of any toilet connected to a centralized system or, it is important to ensure the high-quality and uninterrupted operation of the cistern. It can be said without exaggeration that the quality of flushing food and biological waste, the degree of contamination of the inner surface of the toilet bowl, the functioning of the self-cleaning ability of the sewer, as well as the working volume, and the average daily level of consumption of water used, mainly depend on the correct setting and adjustment of this device.

Features of the drain system of the toilet bowl

The vast majority of modern toilets are equipped with floor standing toilet bowls of the compact system, in which the flush tank is installed on a special ceramic platform, which is an integral part of the toilet body.

This arrangement allows you to minimize the overall dimensions of the device, moreover, provides sufficient pressure for drain water, and, if necessary, makes it possible to carry out routine repairs of the toilet bowl with a button with your own hands, without resorting to professional plumbers for help.

The internal device of the drain tank

Currently, a wide range of plumbing fixtures is presented on the building materials market, the price of which largely depends on the manufacturer, the material of manufacture, the complexity of the internal fittings and the functional features of a particular device.

In order to independently repair a toilet tank with a button, you should be aware that, despite the apparent resemblance, all such devices can have different shut-off and drain valves, which in turn can be of several types.

- Top water supply with a side inlet pipe is most often used in low-cost models. This scheme allows you to quickly install and connect with your own hands, but it differs increased level noise generated by the pressure of the water.

- In the case of a bottom water supply, the device of the toilet bowl with a button is made in such a way that the inlet pipe and the float shut-off valve are located at the bottom. Installation and maintenance of such devices is a little more complicated, however, they have a more aesthetic appearance, and they also differ low level noise when filling with water.

According to the principle of draining water, all devices are divided into two types: single-mode and dual-mode.

- Drain fittings of single-mode type provide for the descent of the entire volume of water with a single press of the drain button. It has a simpler design than a two-mode system, but in some cases leads to excessive and inappropriate consumption of cold water.

- The release button of a dual-mode mechanism, as a rule, is divided into two unequal parts, which can move independently of each other in the case. When you click on the larger part, the entire volume of water is drained, and when you click on the smaller part, only half of the total volume of drain water enters the toilet bowl. The internal structure of a toilet bowl with a dual-mode type button is more complex, however, thanks to this design, significant savings in tap water are achieved.

Note! Some models of dual-mode fittings may have one common button, and portioned dosing of water can be adjusted by the duration or intensity of pressing it during flushing.

Repair of shut-off and control valves

The most common toilet flush failures can be a malfunctioning shutoff valve, or a malfunctioning drain valve.

In any case, to perform repairs, you need to know how to remove the toilet cistern lid with a button so as not to damage its body and break the fragile plastic parts of the internal fittings.

- First of all, it is necessary to close the stopcock, which is located between the supply pipeline and the reinforced flexible hose.

- Before opening the toilet cistern lid with a button, you need to unscrew the outer chrome rim by hand along the thread, which is located at the junction of the button to the cistern lid, pull it out, after which you can easily remove the top cover.

- The first thing you need to pay attention to the float. It must be absolutely tight, and not have visible damage and distortions, as well as traces of friction on the inner surface or parts of internal fittings. If any, it should be replaced.

- Next, you need to check the operation of the articulated lever, with which the float is attached to the shut-off valve. It should have a smooth vertical free play, without jamming and failures.

- To check the operation of the shut-off valve, you need to drain all the water from the tank, and then open the tap of the supply pipeline. When the float is lowered, water should flow freely into the tank, and when the float rises to the maximum level, the shut-off valve should completely block its flow.

- If water does not enter, the internal clearance of the shut-off valve should be cleaned, and if it does not overlap, the rubber seal must be replaced, or the position of the float articulated lever should be adjusted.

If significant faults are found, the easiest way is to buy and install a new set of valves. Such components are consumables, therefore they are sold at any hardware store and, as a rule, have a low cost.

Advice! To reduce the noise level when filling with water, a rubber or plastic tube must be installed and fixed on the outlet of the shut-off valve, the lower end of which should end at the very bottom of the drain tank.

Repair of the water drain system

In case of malfunction of the drain mechanism, before repairing the toilet bowl with a button, as in the first case, it is necessary to shut off the supply of tap water and dismantle the top cover.

- After removing the cover, the first step is to check the integrity of the plastic rod that connects the button to the shut-off valve of the drain mechanism. If any breakage or damage is found, it should be replaced.

- Next, you need to check the integrity of the rubber diaphragm of the drain siphon. Its destruction leads to a constant flow of water into the toilet. To replace it, there are special repair kits, however, in inexpensive models of tanks, it is better to immediately install a new siphon.

- The inner sleeve of the siphon rarely wears out, however, in case of breakage, a spare part can also be found in the repair kit, or a new siphon can be installed completely assembled immediately.

- Another reason for the incorrect operation of the drain can be the ingress of small debris, particles of rust, or fragments of internal fittings between the siphon bushings, connecting rods, levers, or other parts of the drain mechanism.

To eliminate such problems, it is enough to disassemble and rinse thoroughly with water, and then correctly assemble and reinstall all the parts of the internal shut-off valves.

Advice! For those who are interested in how to disassemble a toilet bowl with a double button, we can recommend the same method: first unscrew the round decorative rim around the button by hand, pry it off with anything sharp, and then remove the lid without any effort.

Conclusion

To get a visual representation of the internal structure of plumbing fixtures, you can watch the video in this article, or study similar materials on this topic on our website.