Finishing materials on the pipe in the house. The decoration of the chimney on the second floor or in the adjacent room. Positive Insulated Chimney Factors

The article will talk about how and than isolate the chimney pipe. A few practical ways are presented.

The dehum pipe isolation is required to avoid leakage, as well as overheating cases. Simply put, it allows you to increase the life of the structure. Experts recommend to carry out complex work, which includes hydro and fire isolation.

Bath chimney

When performing the insulation of the chimney in the Ban of the priority should be the safety of people. The main threat indoors comes from open fire. Therefore, it must be protected, after making the overlap resistant to high temperatures.

Baths are mainly made of wood flammable material. Very common misconception is the view that the ceiling by metal sheets will be sufficient. But in reality such protection is not enough. After all, the upholstery will still heat up, which can lead to ignition. The popular solution to the problem is the insulation of the chimney pipe with red bricks. But this is not suitable for every bath design.

Now there are two good options for the isolation of the chimney:

- Folgoisol. The bath with such insulation will not lose heat, everything is working all like the thermos. It warms it pretty quickly, while maintaining the temperature.

- Heat insole. Material is used to wind the chimney.

The popular solution is the use of sandwich pipes that demonstrate high degree security. The design of the insulation consists of several sections, easily united with each other. This option is suitable including for a sauna with a metal stove.

It is important to accommodately approach the brickwork in the bath. From its quality directly depends the duration of the operation of the structure. You can not save on materials or works. After all, the need for repair in the future will be associated with much greater costs.

Metal chimney winding

"How to wind the chimney pipe metallic in the bath?" - A popular question among dacities. After all, there are many materials used for this cottage. The absence of combustible substances in the coating is the primary nuance that needs to be taken into account. It is preferable to use high-quality material with all the necessary properties. It should also be completely safe for use.

The most common materials:

- Glass gaming;

- Fibrous building materials;

- Mineral wool.

Warming of metallic chimney

The insulation of the chimney of the metal chimney is a separate topic for discussion. After all, it contains a number of nuances, which will be mentioned below. This is a very difficult task, so it is recommended to perform it during the construction of a bath. With the finished building it is harder to work, because it may be necessary to restructure the roof.

A good solution will be the use of sandwich pipes. This design is easy to make, in addition, experts will be reduced. However, the material itself does not apply to budget. But the service life and quality fully justify its cost. Sandwich pipes are additionally insulated with mineral wool.

Than to isolate the chimney pipe, each decides itself. It is important to remember what insulation allows you to protect the chimney from the negative impact of combustion products, as well as moisture. If you do not worry about insulation in time, then the risk of battery destruction arises. After all, the reinforced acid condensate slowly destroys building materials. It represents the greatest threat in the spring when the pipe begins to lean (more detailed: "").

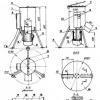

Manufacture of Korobov

About how to insulate the chimney iron pipe was previously said. Now you can go to the next step. Many it seems that the manufacture of a chimney box is too complicated. In fact, it is not. It is enough to approach work responsibly, with knowledge of the case.

Required tools:

- Drill;

- Scissors for metal;

- Compass;

- Metal sheets;

- Saws.

Stages of work:

- Preparation of the hole. At the edges it is necessary to fix the bars that will act as a support for the case.

- Two blanks are cut from the metal sheet. They are attached to the P-shape. Then the finished parts are screwed to the ceiling using self-tapping screws.

- Two blanks are made again, but they are already fixed on the standing sheets with a small intercession. It turns out a one-piece framed in the ceiling.

- Now there is a bottom for a box of metal sheet. In the center of the workpiece should be a hole for the chimney, there will be a circular.

- The box is placed four fasteners in two centimeters. They are cut and rejected perpendicular to the bottom.

- The walls are attached to the bottom. Now the chimney is inserted into the box, it is additionally fixed by clamps. Void is filled with insulating layer.

Installation of chimney

Installing the chimney - not so simple task as it may seem at first glance. There are many nuances that should be taken into account. If you put the chimney is not well enough, it can lead to a damage of property, and still creating discomfort of people inside and harming their health.

Stages of work:

- The preparatory stage where the project project is selected, materials are purchased, the form of construction is determined. There are straight chimneys, as well as structures with various bends.

- Now you can start assembling the chimney. Places of pipe connections, knees and tees should be copped with clamps.

- Conduct chimney through a roof using a special tool. For a start, the level of the roof slope is determined, based on the data obtained, the right place is selected. It cuts out a hole for the workpiece. From above, everything is insulated with a roof cutting, and from the inside - a coated sheet. See also: "".

- A special apron is fixed on the nozzle. The pipe is lengthened to the desired dimensions, its top is partially isolated with a special lid in the form of an umbrella. It will prevent atmospheric sediments into the chimney.

Fastening chimney

The workpiece must be removed to the roof through the attic. All the slots, especially the emptiness between the roof and the nozzle, are filled with waterproofing. When the blank is derived, it is necessary to remember the safety technique.

To fix the chimney pipe apply knee. It is designed to regulate the location of the vertical design. To give all reliability, the pipe is additionally attached to the wall, use suitable brackets. Usually they enter the finished set. Also, they can be made by hand, it is best to use metal corners as the basis for them.

As soon as the insulating structure stood in place and securely fixed, it is necessary to close the chimney pipe with an umbrella. It is designed to protect the design from atmospheric precipitation, poplar fluff and fallen leaves. It is also necessary to think in advance than to smell the chimney pipe, in order to exclude the flow.

Replacing a brick tube on a metal

If the brick chimney is not enough, it can be further lengthened with a metal pipe. The task is time-consuming, but quite implemented. It is important to approach it with full responsibility.

To begin with a flat steel platform with a nozzle. Moreover, its diameter should be the same as the diameter of the metal pipe, which is planned to be used. The platform needs to securely secure. It is fixed with the help of dowels and screws. Additional reliability will add sealing.

Order of work:

- On brickwork, you need to mark the points on which the mount will be installed. They cannot be put on a masonry seam. It is advisable to place them closer to the center of the brick, and not on its edge.

- In the marked places they drill holes for the placement of dowels. At the same points, holes on the flat platform are done, self-tapping screws will go there.

- A refractory sealant is applied to the brick base, then the steel platform is placed there. Self-tapping screws in a dowel. It is important to monitor the density of adjacent and uniformity.

- Now it remains to wait for a complete drying of the sealant and move directly to the elongation of the chimney with a metal pipe.

Important Mounting Nuances:

- If the length of the pipe segment above the roof exceeds 1.5 m, it is recommended to equip it with special stretch marks that strengthen designs (read also: "").

- You can not put the nozzle, the length of which from the stove to the headband is more than 5 m.

- The installation of special glows allows you to get rid of condensate.

- The flue of the chimney above the roof should be longer than 1.5 m.

- It is impossible to strange the nozzle when installing the chimney.

- The designs of flammable materials are not far from farming should not be heated to a temperature of 50 o C.

- Chimney can not be placed near the wiring.

The decision about how to isolate the chimney pipe metallic should be taken on the basis of the budget, as well as the needs of the construction. It is important to approach the task as responsibly, producing work in full compliance with all the rules and nuances. Then the isolation of the chimney will serve a long period without complaints.

The priority of autonomous heating of a private house is increasingly obvious. In addition to essential savings, it is a possibility independent choice Alternative methods of heating. Among the sufficient number of available options are still popular furnace heating. Despite certain difficulties of installation, this is the best way to create a favorable microclimate in the house.

Any autonomous heating, with the exception of electricity, implies the need to remove the combustion products through the chimney. Today there are enough materials with which it can be organized. In the event that this is a refractory brick, it is more expedient to protect it from the negative impact of aggressive environmental factors by cladding.

During the construction of the house, the question often arises: how to solve the chimney of a professional flooring?

The chimney cladding is a kind of shield that prevents condensate, as a result of the interaction of the difference in ambient temperatures and the chimney pipe.

The decoration of the chimney is the beginning of roofing finishing works, because otherwise you can damage the finished roofing coating, or stain it. Visually, both the chimney itself and the roof covering, should be a harmonious tandem, so it is more expedient to select identical materials for their plating.

Depending on what materials it is assumed to carry out finishing work, several options for the trim are envisaged. Each of them has a number of positive characteristics, however, everyone has some minuses.

Ready factory design for chimney

Clinker brick and tile

The method is quite common when the clinker tile or brick is used in the finish. A sufficient degree of strength, resistance to weather conditions and the temperature difference is its main advantages. In addition, this facing coating is not afraid of dirt, which is important from aesthetic point of view. Minus one: the need to use full clinker brick, planted on a special clinker solution, determine the high cost of work. Therefore, this method in most cases is not available to a wide circle of consumers.

Finished Factory Manufacturing Designs

You can sneak in advance prepared material. As a rule, this is a factory version of the pipe that has a steel channel. Through brick, reinforced grid, the plaster is finalizing the chimneys to the perfect state.

Plaster

Speaking about the chimney, which assumes the budget option of the trim, it is worth remembering the old proven method of the stucco of the pummer. Despite the fact that this method is considered the most budget, it is no less durable and reliable.

As alternatives can be considered ways with the use of cement-fibrous plates, slate, etc.

The sheet of profiled flooring is the priority of facing material

The market for finishing and facing materials is quite diverse. The main criteria that justify the selection of this or other options are reliability, strength, durability. However, the price of the material and the ease of its installation is equally important.

Schematic image of the chimney exit

Professional flooring most of all complies with all the above requirements, due to its high technical characteristics:

- Resistance to temperature regimens,

- Duration of the operational period

- Lightness and efficiency of installation,

- Ease of service

- Small specific gravity

- Low cost.

The professional flooring is equally well organized a facing coating of the roof and lining of the chimney pipe. In addition, it looks quite impressive, adding the structure of respectability, solidity, emphasizing the style.

Profile has a fairly wide color palette, which allows you to implement any designer solution.

Varieties of professional flooring suitable for chimney cladding

A wide range of profiled sheets significantly expands the boundaries of affordable cladding solutions. Among the produced species distinguish:

How to get around the chimney of professional flooring

- Combined type sheets used in the organization of various designs of the enclosing and finishing nature,

- Profile of reference type, characterized by increased strength,

- Aluminum profiled sheets characterized by the duration of operational period and increased moisture resistance,

- Painted sheets of profiled flooring,

- Galvanized

- Roofing

- Facing.

Each of the types can be used as a finishing material, and therefore the priority of choice determines the issue price.

Subtleties of chimney cladding

Facing the chimney tube by professional flooring is the optimal version of the finishing events. However, before proceeding with its purchase, you need to know about some nuances of its storage and intricacies of working with it.

By purchasing professional flooring, it is necessary to take care of compliance with the storage conditions. Dry, well-ventilated premises as possible for these purposes. The material is attached strictly horizontal position On a flat surface. Forced open-air storage must necessarily cover a dense waterproof film.

It was originally necessary to make a metal frame. It is he who is the basis for which the skin will be directly attached. The attachment mechanism provides for the nesting of one corner of the sheet to another. Mounting strength is achieved through the use of screws. Aesthetic attractiveness to the joints give special corners used for finishing.

External perfection of the design, its strength, durability will depend on how high-quality installation. It is fundamentally important to carry out the maximum smooth location of the sheets of the lower row. The leaf geometry errors that occur are easily corrected by fair components during the installation process.

Considering the negative ratio of profiled sheets to a high temperature regime, thoughts on the use of a grinder in conducting the stages of the trim, it is necessary to immediately discard. The perfect tools are electric jigsaw and circulating saw with a special blade.

Discontinuous compliance with the requirements ensures that the execution of work is correct. As a result, the chimney will not only be satisfied, it will deserve a lot of incentive reviews.

Part of the pipes that rises above the roofing surface is constantly exposed to external loads, so they need to protect. To prevent a decrease in the functionality of roofing pie, the roof sealing should be made high quality. Also, the appearance of pipes, which must comply with the architectural appearance of the household.

On each roof of a private house you can see several types of pipes - flue and ventilation. The trim of the roof pipe assumes the fulfillment of mandatory sealing at the points of contact of the roofing coating with vertical surfaces, protection of channels from atmospheric precipitation and chimney thermal insulation. In addition, it matters aesthetic design of places for roofing.

Where to position the pipe on the roof

According to professionals, a place in which the pipe goes to the roof should be located as high as possible. An ideal solution is a horse, because it is the highest point on the roof. Here the thrust will be maximum, and the installation of waterproofing is easier.

Chimneys can have a very intricate form. An example is the roof of the chamber of the chamber located on the Loire. It is a real masterpiece, since it has a large number of incredibly beautiful chimneys.

The form of pipes affects aerodynamic characteristics. The caps installed on their headpoint slightly lower the thrust force. Any protrusions available on the pipes of pipes that are in their upper part prevent the creation normal level Ventilation.

Perfect form The pipes are considered to be a design, tapering up, while it should be installed not too large and low cap. To preserve the force of thrust on the headside of the pipes there should be no great extension.

Often there is a need to derive over the roof of a single ventilation pipe. For example, ventilation coming from the sewer riser should be placed separately. It is necessary to prevent overlap with air flows from residential premises as a result of the occurrence of reverse thrust.

In this case, the best solution will be used instead of brickwork of ventilation plastic or metal outlets, which have many types of new roofing systems.

These outputs:

- look aesthetic;

- differ tightness and reliability,

- regulated in height;

- well protect against precipitation.

Sealing brick chimneys

After the guilt of the brick chimney is performed, first of all, the output of the vertical pipes to the surface of the roof should be made hermetic. This is the initial and main stage of finishing chimney on the roof.

More recently, according to state standardsIt should be done above the roof expansion of brickwork. It was required in order to bring roofing material to it in order to seal the joint. To ensure insulation, the compound under the ledge was laid metal. As a result, the vaccine cut of the pipe was severe and looked unattractive.

Currently, after the emergence of the latest isolation technologies and materials, it is no longer required to expand the masonry. Brick tube can be straight, without protrusion. Everything without exception waterproofing films, regardless of the roof design, you need to wrap on brickwork. At the same time, bitumen materials are not allowed for chimneys, you should use non-combustible elastic ribbons.

When the chimney trim on the roof is performed, the protective apron is needed around it. This element is made of galvanized metal having a polymer coating. If necessary, under the apron, the sealing tape is placed - this flexible product is sold in a set with roofs, it happens a different color solution.

They produce such tapes based on aluminum foil, they have a self-adhesive bitumen-polymer layer, sometimes consisting of lead plates. In the manufacture of aprons for smoking structures, exclusively non-combustible materials are involved.

The most reliable solution is considered to be a combination of a metal apron and a sealing flexible tape. If in the process of masonry the grooves was not performed in advance, then it is desirable to cut through the stroke in it to start a metal into the recess. But this is not necessary.

The decoration of the chimney pipe on the roof provides that the apron in its lower and side part must be located above the roof coating, and the top must be

under the coating. The place of adjoining the element to the masonry should be processed by transparent silicone sealants. Also, do not forget about the applied of these compositions in the seam.

Circus pipes above the roof

Perform it in certain cases:

- The masonry was laid out of poor-quality materials and there is a concern that the brick may not withstand atmospheric loads.

- With a sufficient height of the pipe, there is no required thrust. In this case, before we see the chimney, you need to lay a layer of thermal insulation. For smoking structures, a non-combustible material is used, which is basalt wool.

- When only plastic ducts that have light weight can be derived to the roof, then there is no need for brickwork. Instead, a durable framework is built, communications are carried out inside it, and outside after laying insulation make firing.

Materials for firing stoves

Features of the execution of such work are as follows:

- Before putting the chimney pipe, you need to build a frame designed for fastening materials and installation of the heat insulator. For ventilation pipes, a wooden bar cross section 4x4, 5x5 centimeters treated with antiseptics, or metal, and for chimneys, use a metal profile, which usually use when working with plasterboard. Apply dowels from metal, and not from plastic.

- It is convenient to use a galvanized profile for GLC. The fact is that the insulation is well falling into the intervals existing between profiles.

- The most inexpensive and neat material when choosing, than to close the chimney pipe on the roof, can be called a galvanized metal sheet coated with a polymer.

- Metal lining of the chimney structure is a cheap and neat solution. For attachment in this case, screws with a hex head and a rubber gasket are used.

- Even siding can be used for firmware, but only ventilation pipes, since it is a combustible material.

- If a flexible tile is laid on the roof, it can also be lining the trim. First make a frame, after which an OSP or CSP is used, and only then glue the tile. But for chimneys, this option is not suitable.

Specialists are united: decoration of the chimney on the roof of a professional flooring is the most optimal option.

Facing chimney pipes and special caps

One of the trimming methods is facing. This uses natural or artificial stone for this, but this option is not practical. It is explained by the fact that often the facing is broken from a poor-quality brick, while along with the upper layer of ceramics, which spoils the roof. If the brick is high quality and beautiful, it makes no sense to close it.

When the sheath is heavy, it should be fixed not only with the help of adhesive composition, but also by hardware. For this purpose, metal brackets or dowel are involved - nails directly through the stone tiles.

To protect the ventilation channels from atmospheric troubles on pipe shells, protective caps are installed. They reduce the force of thrust, so their size should not be too large. At the same time, the distance from the top of the pipe to the lower point of the cap is needed at least 15 centimeters. The form of this product and the material of its manufacture can be the most different.

To protect the communications from birds from entering them in the holes of the pipes, it is advisable to place the grille or grid.

Chimney finish - how to enjoy

When performing finishing work, it is necessary to adhere to fire standards. Gases emerging from chimney structures have very high temperatures. Mandatory for all types of chimneys is to ensure sufficient thrust.

One of the main requirements imposed on the chimney finish is the use of exclusively non-combustible materials. Therefore, such a decision, how to sew a pipe on the roof of metal profile, is considered the best. When the chimney is installed next to Ventkanals, it must be displayed above the total cap.

Today, stainless steel chimneys that have internal thermal insulation were widely distributed. They are allowed to bring to the roof without brickwork, using a metal apron.

Methods for finishing channels overlooking the roof are diverse and largely depend on the preferences of homeowners. You can take a pipe with a straightener, clinker brick, cement-fibrous plates, lime-cement plaster, artificial or natural stone, ready-made two-circuit design. The last option is convenient and has an attractive view.

The correct operation of the heating device is possible only in the presence of a system of burning products. But it involves the arrangement of the pipe passing through overlaps and roof.

Moreover, the adjoining of the channel to the roof should be sealed, not to have cracks, and to maintain the style of the building it is necessarily facing the most suitable material.

The process of performing all these works or decoration of the chimney must comply with the rules of fire safety, since the gases passing on it heat the structural elements to the temperature capable of becoming the cause of the fire.

- Assembling system

- Facing chimney

- Stages of work when finishing with shale

- Fucker smoke

- Facing wild stone

What needs to be performed during the installation of a chimney pipe, that the equipment worked effectively and was safe for others?

Chimney seal on the roof requires compliance with the following conditions:

The flue of the chimney can be performed on the skate or rope of the roof, and each of the ways have its own characteristics.

The first option may lead to the need to partially change the system of rafters, and the second is to become a pocket for snow. But these shortcomings are easily solved by adding an element under the skate bar, which will avoid leaks.

After performing the passage of the pipe through the roof, it is processed to its sealing. The building materials market offers a wide range of nodes that can be used in various conditions.

Of the traditional options, this is a salary of metal strips corresponding to the sizes of the pipe.

For the roof of the tiles or corrugated plates of the fastening of the elements, they are satisfied with the fold, and on the slope structures with a slope of more than 30 °. Behind the chimney are a special timber. It serves as protection against rainwater.

Waterproofing of the chimney to the roof beavenpheses the arrangement of a protective apron. It can be made of flexible tape or metal covered with a polymer composition.

The elastic apron is installed along the perimeter of the pipe in two layers, the bottom under the roofing coating, and the upper mounting on top and covering it with metal profiles.

Isolation from steel sheets is located on an isolated roof flooring rubberoid. Its individual elements are attached to the perimeter of the channel, starting with Niza. Pages are filled with silicone or polymer sealant.

Facing chimney and materials for her

The finishing works of the exhaust gases removal system are performed before laying the roof, which avoids its damage or contamination. Facing options exists enough to make right choice. Usually, the finish on the roof of the chimney pipe depends on the material from which the structure itself is performed.

It can be:

- Clinker tile or brick

- Plaster

- Cement-fibrous plates

Consider the features of each material. Clinker brick - durable, resistant temperature drops, impact of atmospheric precipitation. Only a full-length brick is used as a facing material, which is performed on a special solution. To fill the seams use compositions for grouting.

We look at the video, what material to lodge the chimney:

Clinker tiles - light, thin, has excellent aesthetic properties. It is used when lining high chimneys.

Plaster is a simple and cheapest way to finish, but with a limited service life. The screed is made of cement mortar sometimes with the addition of lime. But such a cladding from above should have a decorative layer, for example, from silicone paint.

Little-format plates are one of the most durable and resistant to the effects of aggressive media. They have an attractive appearance and non-combustible.

Trummage pipe shale: stages of work

Wedding to the width is not only for the best preservation of the design of the chimney, but also as a decorative finish, therefore it is customary to perform from the materials that are most suitable under roofing. One of the most durable, durable, and also very aesthetic is a tree.

Its color depends on the field and may be:

- Purple

- Green

- Graphite

It can be in the form of tiles or panels. The shale fastening is possible with the help of copper nails with a wide hat with a diameter of 2.5 mm and a length of 40 mm.

When performing work, it should be borne in mind that when temperatures are deformed materials. Therefore, nails are not nailed to the end, there is a small gap between the hat and tile.

The installation of the tile is performed on the crate, the bars are fixed in the corners of the chimney, and with its width, more than 60 cm will need another additional bar.

The decoration of the chimney on the roof is performed in several stages:

- Extreme guides are exhibited according to their level stretching the rope (from above, below and in the midst - at a height of more than 2 m), and then intermediate bars are exhibited.

- If necessary, a smoke canal is warmed.

- Plywood sheets are laid on the guides

- Tile laying is made (its installation is performed in such a way that one can go to another in the range of 1.2, and the angle was not less than 22 °

There are several ways to lay a slate - from the standard rectangular, to a fish resembling fish. They are chosen taking into account the roofing pattern.

Fucker smoke

The easiest and cheap facing method is considered to cover the surface of the flue channel cement composition. But such a cladding has a non-primary look and is also short-lived. Therefore, on top of it, it is recommended to apply marble or Venetian plaster.

The first is performed on a pre-primed surface. To do this, the bucket is diluted with a dry mixture in the proportions specified on the package. Note that it is usually sold white, and a color is added to obtain a colored coating.

The diluted composition is applied with a thin layer and is left to dry, and then heated with a steel brush. Next, the second layer is applied - if necessary, the specialists are still recommended to be limited to one. The last stroke is the surface treatment with a grinding machine and grout with an iron spatula.

Venetian plaster Unlike marble is considered expensive pleasure, but it looks amazing. Especially if you do everything yourself, you can save a certain amount of money.

It is also for sale in bags, it has a white color and for applying is divorced with water with the addition of a flaker. Applied with a spatula or celma. But to obtain high-quality coverage from Venetian plaster requires the use of forced drying technology with a construction hairdryer. The cracks that have appeared are processed by paint or varnish and, after drying, polished with a grinding machine.

Wild stone as a facing material

Another embodiment of the chimney can be the use of natural materials. A wild stone has proven itself in this role. It is placed on cement using a plaster mesh fixed on the surface for clutch stiffness. The seams are close to cement with the addition of a kolator.

And the last stage of work related to the arrangement of the exhaust gas removal system is the chimney finish inside the house. It can be made of various materials whose choice depends on the indoor interior of the room.

The importance of chimney decoration

In this article, we considered the assembly, insulation and facing of the combustion products. Each of these stages is mandatory for the effective operation of heating equipment, but can be performed using various materials. Which one is the best - to solve only you. After all, it depends on constructive features chimney and from the architectural style of the whole building.

Roofing pipe

According to professionals, the pin with the roof is best to perform through the horse, since in this place, perhaps, it is easier to arrange a node of the roofing coating knot to the pipe, and this can be avoided by the formation of snow pockets and, therefore, reduce the likelihood of leaks to a minimum. .

However, in this case, the need for creating rafter system Roofs without a device of the railway beam or the execution of the beam break at the point of passage of the chimney pipe with the installation in the opening places of additional supports.

Another nuance is that for round-section pipes, manufacturers, as a rule, do not produce components, with which it would be possible to pass the pipe through the roof.

Therefore, we are talking only about smoking pipes of rectangular and square sections.

Another successful method of the relative roof pipe is located near the skate, on the skate, which will also avoid the formation of the snow bag and from a technical point of view will be relatively simply feasible.

Pipe height over the roof

The height of the pipe over the roof depending on its placement

The pipe through the roof is not to be installed, where there are endands - the joint of two rocks forming the inner corner.

It is very difficult to achieve high-quality adjacent coating to the pipe here, with an additional load on the smoke pipe (including from the point of view of its sealing) will create an aqueous stream collected from the adjacent rods, and in winter it will form an extensive snow pocket

Hermeterement Pipe on the roof

As a rule, the sealing process between the body of the pipe and the roofing plane is implemented using the finished sets purchased together with the roofing material. Moreover, one set is used for chimneys of the square section, and for round pipes - completely different.

Sealing roofing and pipes are implemented using a special detail - apron, spherical or rectangular shape. Such an apron is put on top of the pipe so that its edges go beyond the border of the box in which the chimney was mounted. And on the roofing material of the apron, it is simply superimposed, and the pipe is attached to the self-tapping screw. The junction between the pipe and the apron close up with heat-resistant sealant.

Sealing chimney pipes of round-section can be implemented using an apron-cap, dressed over the pipe. The conical ledge of the cap, while cut under the desired diameter.

The process of sealing the top of the pipe, in a simplified form, is as follows:

- At the very beginning, the remnants of the roofing material covering the box are removed.

- Next, the edge of the roof is glued with a layer of elastic waterproofing.

- On top of the waterproofing layer, the apron is mounted, the lower edge of which is placed on the roof, and the upper one is on the pipe.

- The contact points of the apron and the roof are fixed on a screw with wide "hats" of a rounded shape (roofing option).

- The apron is fixed to the elastic sealant. After that, the junction of the pipe apron is pressed by a clamp.

Types of chimney pipes

Chimney pipes on the material from which they are erected are divided into brick, metal, asbetic, pipes - sandwiches and modular.

At the installation site, chimneys are:

- Wall - when the pipe is located in the capital wall of the building, internal or outer; on bent when the pipe is installed directly on the furnace;

- Suspended - the chimney pipe is attached to the outer wall of the building;

- Indigenous - When the chimney has a view of a detached design next to the stove

Support pipes and requirements for them

In order for the chimney to reliably allocate the flue gases, provided traction and was fireproof, it must comply with certain requirements.

Height of the chimney. It is believed that the higher the pipe, the better the thrust. On the one hand, this statement is correct, but has certain limitations. Passing through the pipe, the gases are cooled, and the higher the pipe is the stronger. And this in turn leads to a decrease in thrust, smoking and appearance on the inner walls of the condensate pipe. It accumulates and flows into the oven.

Cross-section of the chimney. In addition to the height of the chimney, there is another important parameter - the size of the section. It must fit the power of the furnace: what it is more, the more lumen in the pipe. Reducing the section leads to the fact that the flue gases do not have time to be removed from the furnace and it begins to smoke. If the lumen is overestimated, the flue gases begin to move slowly and cooled. It also leads to a decrease in the thrust and the appearance of condensate.

Heat production of chimney. The same result also leads the increased heat transfer of the pipe. Only here for another reason: not by reducing the speed of smoke movement, and because of its rapid cooling.

Heat resistance of the chimney. When choosing a pipe, it is not a latter role to thermostroopy. Despite the fact that the temperature of the exhaust gases is usually below 300 degrees, the inner surfaces of the pipe must withstand higher temperatures - up to 500 degrees long and up to 1000 degrees during 30 minutes. The last requirement is associated with the possibility of ignition in chimney of soot, the combustion of which passes at high temperature. Outside, the pipe should not be heated above 90 degrees, and in places of adjoining to marked structures - above 65 degrees.

The mechanical strength of the chimney. Chimneys need to be made from materials providing high mechanical strength. For example, in a fire, the pipe must maintain the structural rigidity within 90 minutes. The inner surface of the pipe must have chemical resistance. Since flue gases and condensate have properties with increased chemical activity and can destroy the pipe from the inside. And from the part of the pipe that is towers on the roof of the house, frost resistance is also required.

Brick pipes

Properly folded from high-quality ceramic bricks, pipes usually meet all the requirements listed above and differ in capital capacity and durability. The disadvantages of such pipes include the complexity of their construction and high weight.

But the ubiquitous construction of closed fireplaces in country houses led to some changes to the requirements for brick pipes. The fact is that the flue gases emerging from the fireplace insert have a temperature of 400 degrees (in traditional brick furnaces - 250 degrees). Therefore, the smoke tube is recommended to build from a special ceramic brick, horizontal seams should be a thickness of no more than 5 mm, and the pipe walls - 250 mm (at 120 mm, the pipe is heated to 150 degrees, which is unacceptable). Following these requirements significantly increases the cost of the pipe and its weight.

Asbo cement pipes

IN coloring constructionWhen building small houses, baths and summer cuisines have long been applied asbetic pipes. They are cheap, lighter brick and quickly mounted. However, sometimes with severe heating, they crack, which can lead to a fire. Usually outside surface Such pipes are very heated.

Steel tubes

Steel pipes are usually used for bourgeokes, bath furnaces, gas boilers. The main disadvantage of these pipes is during a short time they go beyond. Smoke in them, as in asbetic pipes, is quickly cooled and causes abundant separation of condensate. And the high temperature of the surface of the metal pipe makes it fire hazard. From the point of view of modern requirements, single-layer steel pipes are unacceptable. They must be concluded in an additional non-aggravated shell (steel).

Modern types of pipes

Mostly modern chimneys are collected from finished elements or sections made in factory conditions. The object's task is reduced only to the connection of these sections. Such pipes are well insulated, fireproof, acid resistant and adapted to remove smoke low temperature.

The so-called sandwiches are the greatest distribution, consisting of three layers: internal, made of stainless steel, medium - insulation, and outer casing of galvanized iron or stainless steel. The pipe is collected from sections about a meter. At the same time, the sections are of different diameters, which makes it easy to choose the pipe needed for the furnace.

The advantages of sandwiches are simplicity of installation and low weight. They do not require a separate foundation, which reduces the cost of installing the pipe. But, as far as I know, the price of the elements of the sandwich themselves is great enough and in general such a pipe will cost more than the same brick equal in height. In addition, when heated and cooled, the individual elements of the sandwich can be moved relative to each other, which leads to the loss of tightness of the entire system and the emergence of fire hazardous situations. The shelf life of such pipes is about 10 years.

The modular pipes collected from the finished factory elements are increasingly popular in oven construction. These are multilayer structures consisting of a refractory inner core (stainless steel or chamotte tubes), basalt insulation and a solid concrete solid. Such chimneys have increased refractory, chemical resistance and rigidity. The outdoor temperature of the pipe with an intensive firebox is only 40-60 degrees, which allows you to apply any materials when finishing pipes. Such pipes may adjust the combustible designs.

Chimneys are easy to assemble both inside the house and outside. The cost of modular pipes is comparable to the cost of steel three-layer chimney. Lifetime - up to 30 years. Weighs the trafficphone meter of such a pipe of about 120 kg (the brick meter is 2-3 times heavier).

Chimney pipe cladding: materials characteristics

The chimney is finished to lay the material for the roof, which avoids possible damage or contamination of the coating and significantly facilitates the work.

There are many variants of chimney cladding and choose it depending on the type of material used in the performance of the chimney.

A rather practical solution is considered to use clinker tiles or bricks. They are not visible to dirt, they are well harmonized with any kind of coating for the roof.

Clinker brick is distinguished by its strength and resistance to sudden temperature drops and the aggressive influence of the atmosphere. When cladding uses an exceptionally complete brick. It is placed on a special masonry solution, and the seams are filled with special compositions for grouting.

Clinker tiles compared to brick easier and thinner, however, it looks no worse than it.

Clinker tiles are more suitable for lining of very high chimneys.

Chimney can also be separated by plaster. This is a comparatively chimney finish of the stucco, the most easy and affordable method of finishing, but, unfortunately, not particularly durable. For finishing works, a tie of cement or lime-cement mortar is used. To increase the endurance of the finish, respectively, and its service life, the screed is covered, say, silicone paint.

Mineral, acrylic, silicate and silicone species of plaster are stronger than traditional.

Little-format cement-fibrous plates are durable, resistant to moisture, UV radiation and sharp temperature drops. They are nonsense and environmentally friendly, externally quite attractive. Plates have a wide range of colors and a small weight. The surface of them is absolutely smooth or structured.

the decoration of the roof is tinned and the roof is also placing an extremely durable and durable natural material - slate. Depending on the deposit, the slate has a purple, green or graphite color. Plates from this material have different shape - Rectangle, arcs, scaly, octagon.

Facing the chimney inside the house

The choice of chimney facing material inside the house largely depends on the stylistics of the room. You can lay out it from clinker bricks, enter into a brutal interior without additional finishes.

The most ancient way of finishing is shuffling. Suitable for the interior in the style of "Rustic Izba". Chimney can be cooled or painted with high-temperature acrylic paint resistant.

Facing a fireplace and chimney with refractory cafenel, tiles, tiles-majolica, clinker tiles or natural stone will help to decorate any interior, the good the modern market is rich in a variety of materials. The choice depends on the style, financial capabilities and taste preferences.

The main thing is to remember - the finish must be safe for the life and health of people living in the house.

Roof chimney finish

Around the chimney throughout its perimeter, at the outlet of the pipe on the roof, a two-layer protective apron is satisfied. The first layer is started under the roofing coating, the second is arranged over the coating.

Such apron is called salary or collar, performed from metal (galvanized or steel sheet). Currently, ready-made salaries can be purchased on the construction market. Places of adjoining apron to the pipe must be sealing.

The need for additional decoration of the chimney on the roof is caused by the following factors:

- pipe laying is made of poor-quality material (bricks);

- there is no traction, it is necessary to perform additional insulation of the pipe;

- the appearance of the pipe does not correspond to the appearance of the house, decoration is required.

What to close the chimney? Any material should be resistant to atmospheric precipitation and any influences (wind, sun, temperature drop).

Under any pipes, it is necessary to make a frame for fastening the finishing material. The frame is performed from an antiseptic timber or metal guides. The chimney cladding is arranged only on a metal frame.

The drying of the chimney and ventilation pipes on the roof can be galvanized metal coated with polymer. In appearance, it is smooth or profiled (corrugated). This is perhaps the most inexpensive finish option.

The most practical solution is the chimney made from clinker bricks. But you can simply bind the pipe with clinker tiles, which is combined with many roofing materials.

The decoration of the chimney with artificial or natural stone, which is used in the finish of the facades.

The material of the finishing material should be non-combustible, a lime-cement plaster can be used as a finish. In this case, the plastered pipes will be combined with plastered facades, the building will look only.

Two-wall (double-circuit) pipes of the Sandwich type are also applicable to the chimney device. You can read this topic about this on this topic.

Uninstall the chimney can be cement-fibrous plates. This non-combustible material has an attractive view, produced in different colors.

The use of siding is only suitable for the lining of Ventkanalov overlooking the roof.

The choice of material here is much wider, up to the roofing material used for the roof device (metal tile, soft roof).

However, the chimney of a completely unconventional form can be the main decoration of the house.

Types and installation of chimneys in a private house

Such chimney will not require additional finishes.

In which roof is best located the pipe

The higher the better. The perfect place is a horse, the highest point. First, the thrust is maximal, secondly, waterproofing is easier and more reliable. It is also necessary to take into account that the farther from the skate is the chimney, the more should be higher. It does not paint the roof and complicates its design. The roof of the Masterpiece of the Renaissance era, the chambor castle on Loire is crowned with a set of chimneys a very intricate shape. Now you do not know how even in France.

Roof in the house do it yourself

Stages of roof construction in the house of LSTK

Roof Frame house based on LSTK technologies

Plastic waterproofs in a frame house from LSTK

In addition to its classical technological functions, the chimney must and respond to the aesthetic design of the room, without disturbing the design, especially for indoors. Remember that the chimney decoration inside the house should be carried out not only from the ratio of beautiful material and external view, but still remember the fire and construction rate of the Regulation.

As already above, it was written, focus not only on our own design developments and "trends", but also on the correct installation of that or other material, depending on the type of channel. After all, a beautiful and weighty stone or tile is suitable for each chimney. Calculate the weight and overall support abilities. For example, for brick buildings, there should be no serious problems for serious problems, but metal pipes for which a weighty foundation or fastening is not provided, will not be patched with cumbersome. Therefore, think about before separating the chimney.

Traditional methods of finishing

The covering of your chimney can be performed by a variety of material. But, consider that in addition to the most facing material, it is necessary to make the manufacture of a special building, crates or a chimney box, in particular, it concerns ceramic and metal structures. For example, it often uses light tiles of different fractions and dimensions, depending on the designs themselves. As for brick structures, here, of course, preference is given to facing bricks, mramor and tiles. Although in fact, the assortment of facing elements is huge. The most traditional existence of such structures, the classic plaster was considered, which can be performed for all types of channels, with some reservation by the acquired solution.

Facing the furnace and chimney with ceramic tiles

Modern methods of finishing chimneys

Facing the chimney inside the house can be performed by one of the presented ways:

- Stucco, both classical and variations of Venetian or marble.

- Wild stone.

- Clinker brick.

- Facing shale.

Clinker brick and tile

Facing in this way is the most practical, from the point of view of long-term operation of the channels. During the use of a chimney pipe, such materials are experiencing climatic temperature differences, precipitation and the like. In addition, due to the high mechanical resistance, the tile can be used not only inside, but even outside, namely, on the headings, under the roof roof roofs.

Facing a fireplace and chimney with clinker bricks

Plaster

Plaster is more often used, due to its relative cheapness and not demanding. As a rule, combine classic colors, picking up soft tons, under the design of the room. In addition, you can create a variety of patterns, combining color gamut. In the house, it is possible to use the plaster without fear, but using it on the street, have the species of the mixture. Not each solution is suitable for street facing, due to temperature features and mechanical wear.

Natural facing slate

Such material can be used without concerns even on the street, the form of its natural origin. Similar elements are endowed with all weather pranks. In addition, they have a good margin of strength in terms of mechanical damage. Perfectly combined on brick and ceramic pipes. Special attention is paid to the solution or glue so that it is fire-resistant and can be transferred, if necessary, high temperature differences.

Facing wild stone

Such a material gives the house of an aristocratic species and allows its owner to highlight its dwelling from the gray and monotonous mass of other buildings. When using a facing stone, special attention is paid to the smelting of all seams, especially for the interior decoration. But, often the wild stone is common, as a means of facing exactly from the outside, the form of its natural and presentable species. In addition, the wear resistance threshold also surprises such elements.

Camped chimney on the second floor.

This is a crumb, where particles of small pebbles are kneaded in solution. Facing, thus allowed only inside buildings, as the baby does not like the effects of cold temperatures. It is perfectly combined with fireplaces and traditional furnaces, especially if it is additionally finished a kitchen area from such a crumb, not to mention the brick chimns.

Venetian plaster

On sale is a white powder, which when applying must be dissolved in water. Optionally, you can add different colors, which is why the rich selection of shades. Consider that the decorative cladding should be performed on a pre-prepared basis - plaster. After applying (using a spatula), it is recommended to dry the hair dryer.