How to make a chasing. Master class of foil chaskanka do it yourself for kids chasing on a brass leaf on the topic of a bath

Checkanka - One of the species of ancient decorative and applied art and metal artistic processing.

Checkanka - The technological process of manufacturing a pattern, inscription or image, which consists in knocking out on a plate of a certain relief.

Metal chasing It is one of the amazing arts. Metal bag and its ability to stretch well used more ancient artists and masters, but today traditions and technique Chekanka exist, including thanks to our checkners.

Metal chasing - This is an extensive section of metal artistic processing, which covers a variety of products, various in its artistic principle: from relief ornamental to the corner and round figured compositions, from linear graphic two-dimensional solutions to volume-sculptural three-dimensional products.

Metal chasing - the most difficult of all kinds artistic chakeankaSince when working on sheet metal, you need to create a drawing, and the relief, and the texture of the material in the process of work, and chakeanke On the injection, only the identification and completion of the previously created form, cast from various metals, occurs.

Present Checkanka - Complex and demanding high professionalism skill. Professionally make a chasing - A small product or a large picture that will deliver the undoubted pleasure to you, friends and loved ones - can only experienced master chaser.

CheckankaCompleted by ours masters of Chekanka, never remains unnoticed. Pictures, interior items, chased products - will become a pride object and emphasize the unique style of your home or institution.

Chacking - types of products

Checkanka Widespread in the manufacture of various decorative and artistic products from copper, aluminum, brass and other materials.

Now Metal chasing It is widely used in investigative architectural work, in the manufacture of reliefs, sculptures. Also Checkanka It is used when creating dishes, decorative panels, various jewelry.

Our masters Chekanka Use technique artistic chakeanka, creating unique works, applying unique technological techniques.

In technology chekanka Many of their professional secrets giving various artistic effects. Knowledge of most of them and great practical experience production of chakeanka let us guarantee high quality chekanka .

Checkanka and the type of work performed, first of all, depend on the wishes of the customer and the style of the interior, which is planned.

We perform chakeanka to order:

- we carry out the development of sketches for paintings, interior design under Chakeanka and sketches for exclusive products

- we make products from classic to multilayer paintings, including a combination of metals to give multicolor

- we carry out the manufacture of interior parts from artistic chakeanka varying complexity on specified sizes

- we make the finishing finish from classical blacks before making the metal of various colored shades

- implement installation chekhans Fragments in wooden furniture

- apply chased art In the car and moto tuning

- worn tables S. chekhanny Surface and tempered glass

- beds and dressers with manual wood thread and elements chekanka

- chekhans columns and shirms chekhans Cornis

- panel is Chekanka and paintings

- copper trays and plates

- fireplaces, mangals, etc. with elements Chekanka

We can arrange individual author's Chakeanka Luxury restaurants, interiors of apartments, country houses and cottages.

Production of chasing - types of chasing

To create a unique and individual Chakeanka For you, we use several traditional ways.

Openwork Metal chasing

This kind of chased craftsmanship is also called "iron lace". Background Images carved with special sections, then cutting over these lines. Annealing of such chased products is made with special caution so as not to melt thin partitions.

Often material for openwork Chekanka serves a ready-made bulk product. In this case, we carry out the main condition production of chakeanka - Observe the rhythm of emptiness and drawing lines so that the result is a beautiful openwork ornament.

Contour art Chacking

Contour Checkanka Performed on a flat sheet metal without flushing relief. Contour Checkanka It reminds engraving, but, unlike the latter, it can be both concave and convex. Most often contour Chakeanka Various interior items are decorated. It looks very good ornament made by contour artistic chasonka In one line. At the same time, to give the lines of additional clarity, the background can be slightly lowered. Also often background is covered with small ornament.

Checkanka on bulk products

This species Chekanka There are features. It is more compared to Chakeanka on a flat surface. But with such a complex work, our successfully can cope with chekhanshchiki. At the same time, when creating a picture, taking into account the shape of the product, we make several sweeps - flat images of the future volumetric product.

Production of relief

It's the most difficult part production of chakeanka . High relief is usually dyled by a combined way. Initially, general contours are discovered, and in the next stage, the product attracts relief and the form is finally aligned.

Final system reader

Detailed processing of all forms Chekanka It is produced in the latter. This work is aimed at creating a completed type of product.

Big role in giving metal chasing Additional shine plays background and texture chekhans surfaces. A very advantage is a combination of various ornaments, matte and smooth surfaces, other stylistic techniques and their combination.

Styles of Chekanka

Beautiful decorative properties Chekanka Allow us to create new interesting and unique products, both in the established traditions of this type of creativity and add their forms of filing.

we we make chasing Basically in historical, modern and ethnic styles (East, Moroccan, Georgian, Uzbek, etc.).

But we can execute artistic chasonka And in ancient Russian style, and in modern.

Chacking - Types of Materials

We use such metals for Chekanka As copper, brass, aluminum, in rare cases - steel.

Material for chased work Serves sheet metal of various thickness. One of the main properties metal for chasing is its plasticity, i.e. The ability to deform under the action of external forces without destruction and give residual deformation.

Most often we use sheets with a thickness of 0.2 mm to 1 mm. However, for large-scale work with high relief, we apply and thicker sheets, for example, for changing on the media - Red copper thick up to 2 mm thick, for aluminum products - sheets up to 2.5-3 mm.

For artistic chakeanka We mainly apply sheets with a thickness of 0.3 mm to 1 mm, for construction work, for example, for squares, gates, wickets, barbecue, hoods, etc. - Sheets thick from 0.8 mm to 3 mm.

Metals and alloys for Chekanka - Features

- Red copper

For Chekanka Red copper applies quite wide. Red copper has exceptional plasticity and viscosity and easily restores its plastic properties after annealing. From copper easy checker. It easily takes the most diverse shape, admits a high relief to be painted. Copper is well rolled, it produces the finest sheets and ribbons (foil), the thickness of which is not more than 0.05 mm. In addition, copper is highly resistant to corrosion. Chang from media Perfectly stored outdoors without coatings.

- Brass

Brass - copper alloy with zinc (up to 50%), and sometimes with additives of small quantities (up to 10%) aluminum, iron, manganese, etc. Most brass has a beautiful golden yellow color. The brass is well processed on the cutting machines, polished and retains the polished surface for a long time, it is well welded and rolls both soft and solid solders. Most brass rolled well, stamps and copinated. Brass is easily and firmly covered with various galvanic coatings - nickel, silver and gold. Brass is inferior to copper in plasticity, but has a greater hardness. Brass adopts chemical oxidation well.

- Aluminum

Aluminum foil for a long time saves high plasticity, does not require heat treatment. This material allows for a long time to work on one ornament, leveling errors. Aluminum and its alloys (leaf) copinated Very gently and easily, allows for a deep hood, but requires a special precaution during annealing, as it has a low melting point and cast color do not allow trace the annealing.

- Roofing and stainless steel

For Metal chasing Some simple ornamental products can be used sheal roofing steel (roofing iron). It allows you to produce Chakeanka Without deep drawing, the so-called contour chekanka With the lowering of the background and the application of the invitation.

Stainless steel (chromonichel) - beautiful, modern material that copinated difficult. It is used for large exterior ornamental products. Stainless steel is distinguished by high corrosion resistance. For artistic chakeanka Sheet steel is used to 0.5-0.8 mm thick.

- Nickel alloys

Nickel alloys also apply to chased work. Melchior and nezilber are most often used from these alloys. The copper content of them is quite high (81% and 65%, respectively), so they have sufficient plasticity, they are well polished, easily take a variety of finishes and various shades when exposed to solutions of sodium hyposulfite and leadcase.

- Black metals

Black metals - soft low-carbon steel, pre-annealed and etched, so-called decopyr - the material is more difficult in Chakeanke Compared to copper, but very beautiful in the finish. From the decopyr you can checker Both small decorative products with drawing various textures and large decorative products, allowing to dig a high relief.

Production of chasing - processing of the finished product

Main steps production of chakeanka - The sheet metal creates a style drawing, then executed Checkanka And then - the final finish.

Final finish Chekanka Allows you to make a complete type of product, so create the necessary protective layer.

In processing metal chasing We carry out the following types of finishing:

- Grinding and polishing

It is performed to give the product of the completed view after all chekhans work. It is done not only for beauty, but also in order to art Chacking It became more resistant to corrosion and oxidation.

- Patinating

Patinating is processing metal chasing Compounds of sulfur or chlorine.

After polishing Chekanka Completed, you can give the product a variety of color shades by treating various chemicals. As a result of their interaction with the metal, new compounds arise, which form an immemorable flare on the surface.

Depending on patination technology Chakeanke You can give a grayish color, black bloom or completely black. You can also get the whole range of shades from brown to black. Color Chekanka When patting it turns out more saturated.

Brass patination allows you to get dark with beautiful colors or Checkanka May be painted in gray, green, blue or purple color.

- Copper and brass painting

Allows you to paint copper Chakeanka In different colors - from orange to dark red. Way brass chasonka There will be a similar range of paints, more displaced in the direction of yellow.

Brass can be painted in a dark brown or more rich color with a reddish tide. For brass color, we apply as a chemical method (see Patinating) and a mechanical way of coloring with powder paints or shallow metal dust of various colors. Subsequently, surface treatment is performed. Chekanka varnish.

- Enamelling

This method of staining is most often small articles or their individual sections. Enamel is a glass alloy containing various color supplements.

- Oxidation

This method of surface treatment artistic chakeanka makes it possible to get different colors. Accession of copper and brass allows you to give Chakeanke Various color from green to black. Aluminum oxidation is well protected by corrosion chasing, allows you to get a color saturation and a rich gamut of shades - from blue to black.

- Towing

Towing is the process of investing in a metal thin wire, which makes it possible to emphasize the drawing boundaries.

Order production of chakeanka We, and you get the best quality and copyright.

Checkanka

TO Manager:

Artistic processing of metals

Checkanka

The chasonka is an extensive section of metal artwork. It covers a wide variety of products, risen in its artistic principle: from embossed ornamental to the corner and round figured compositions, from linear graphic two-dimensional solutions close to engraving, to volume-sculptural (three-dimensional).

The chased technique also applies to perform the simplest operations (packing of texture) and for the finest modeling of human individuals and figures, in some cases miniature jewelry miniature, in others - the chasing is treated with many-meter monumental aluminum, copper and steel monumental figures. The presence of such a variety of technological methods of chasing gives a different artistic effect, is explained by the fact that the chasing is very ancient, developing throughout the centuries. The chasonka was known in ancient Egypt, ancient Greece and Rome. From a long time, it is known in the art of Iran and China, India and Japan. Significant development she received in the Renaissance Epoch in Western Europe. High perfection of the chasing reached in Domongolian Russia and blossomed in the ancient Russian art of the XV-XVII centuries. She received further development in the XVIII and XIX centuries. And continues to be applied and enriched with new techniques in our modern decorative and applied art.

For example, the checked products of Novgorod Chekhanger XI-XII centuries have been preserved. cult nature (salaries of icons, etc.), in which the features of Russian and Byzantine art are peculiar. These are not only ornamental compositions made by leaf chasing, but also chased cast figures. By the same time, the samples of the chased art of Vladimir-Suzdal Rus are belonging. By the beginning of the XV century. (1412) These are the work of Master Lukian (folded), made in the technique of chasing with a mobile, as well as the work of Tver jewelers, made by chasing on a silver openwork. High-relief chasing from sheet silver was made by the Greek Masters in Moscow, and the chased buckets and bowls - in Novgorod. Especially high and lush heyday reached the chasing in the XVI century; In Yaroslavl, she was combined with carvings and engraving, in Nizhny Novgorod he was enriched with licensed sculptural details. Novgorod chaseners began to apply a chasing with confeded backgrounds. Cups, bowls, buckets were minted and drifted. The flourishing of chased art continues in the XVII century. New techniques and artistic features appear: from the second half of the XVII century. and early XVIII century. In Novgorod, the chashangers apply a slit ornament, a flat crushed chaconer develops in Kostroma, alternating with casting and threads, the chasoker reaches a special magnificity in Yaroslavl - enamel is cleaned. In 1630, the Moscow chasecan Gavriil Evdokimov performed a three-dimensional chased sculpture of Tsarevich Dimitri in growth.

The artistic chasonka is divided into two independent types of works that have high-quality differences in production technologies:

1) leaf chasing;

2) chasing on casting, or frown.

In the first case, from the sheet blank with the means of chasing, they create a new artwork; In the second case, it is only revealed and completed with an artistic form, a previously created sculptor and cast in a metal (or carved Obron technique).

The following metals and alloys are used in the modern practice of chasing from the sheet:

a) non-ferrous metals - red copper and its alloys (brass, tomopac) _Materials most suitable for chasing decorative products and sculptures. They possess high plasticity, it is easy to double, allow a deep hood - the chasing of the cores and round sculptures, are well annealed and diverse. Nickel alloys (Melchior, Nezilber) are currently applied rarely, but in the past (especially at the end of the XIX century. / Widely used for the chasing of artistic dishes, imitating silver. The stingy zinc has enough plasticity, but requires special techniques. Sheet aluminum minimizes very gently and easily, admits a deep hood, but requires special precautions during annealing; Dural - hard material, it is difficult to minimize, but it gives interesting imitation of silver;

b) ferrous metals: soft, small-carbon steel, pre-annealed and etched - the so-called decapir (or twice treated steel before and after annealing - twice decapir) - the material is more difficult in the chasing compared to copper, but very beautiful in the finish. This material can be recommended for the chasing of large decorative products that do not require fine detail. As well as copper, it allows you to pull a high relief.

For some simple decorative techniques of chasing (expense, the sparkle - see below) can be used shelving roofing steel (roofing iron). Stainless (chromonic) steel - beautiful, modern, very spectacular material, but it is minted hard. Can be used for large, exterior ornamental products.

In the past for the chasing of unique jewelry, expensive dishes (buckets, cups, cups), as well as church utensils (salaries of icons, liturgical books, etc.) used precious metals, silver and their alloys.

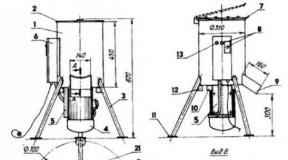

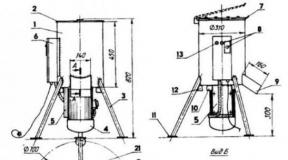

Fig. 1. Chakeanka

When working, the checkman holds in her left hand with three fingers, leaning off by a ring finger (a little finger remains free). The elbow should be on the weight, it provides the mobility and maneuverability of the hand. Cecains are not kept strictly vertically, but slightly tilted back so that its working surface (fight) is raised to raise and as a result, when the hammer is constantly moving forward. In his right hand, hold the chased hammer, which are applied by rhythmic blows on Chekana, promoting it.

For the acquisition of chasing skills, a long training is needed. It is necessary that the corresponding force and the speed of strikes are combined with the achievement of the desired modeling. Three stages can be distinguished in the mastering of the chasing techniques: the spending, the creation of the relief and finishing (application of the invoice). Consumables Reaching the creation of contour pattern on the workpiece, which is performed by the Ras Wallman. From engraving, the spending is characterized by the fact that its in-depth lines are much more gentle, softer, since it does not turn into the chips, and the metal is depressed.

First, it is very difficult to make a smooth uniform line without excessive recesses and sowing; Only due to repeated exercises, a sense of coordination of the maintenance of Chekane and the hammer impact; Then we can assume that a large technical problem is solved in the acquisition of the skill of the chasing. This first pinway is particularly necessary in case of chasing fonts or strict ornamental lines. On the contrary, when simulating with facial or reverse side, a relief image is obtained due to the processing of various checks.

Fig. 2. Chekani: A - Bannik; b - consummer; in, g - shuthesterns; d - pillow; E - Sapozhok

With low (low) reliefs and images, it is enough to form them only from the front side. If the convexity of the relief should be clearer and high, you can raise the relief from the rear side. More often the contour is planned from the front side (RESPACT) and then moderate from behind, since with such a form method will be very clear.

Due to the finishing and application of texture on a modeling ornament or other relief, the completion of work is achieved.

The following checks groups are distinguished (Fig. 2), having a different form of battle, depending on their purpose.

Kanfarniki - Chekani with a pointed end in the form of a stupid needle; For minor work - more sharp, for large works - stupid. Banquarters serve to translate drawing with paper on metal, as well as for finishing the backgrounds points ("Banfarming"),

Consumables, or bypass checks with which on the metal reproduce the contour of the pattern, rubbing it at the points of the canfarney in the form of a more or less rolling solid line. Wide (thick) consumables give a softer line, sharp - on the contrary, it is dry, clear. Consumables are straight lines - for carrying out rye lines and semicircular with different radius of rounding - for stroke of curves of lines in Fig. 3 shows the first academic work, performed! The speaker, and in fig. 4 - Fragment of the composition made by a consumator. 'Lobcakers (from "Lo_ Short") - the most sewn. Naya and diverse group of checks with a more or less flat fight. Apply to the rugging, leveling of planes and smooth surfaces. Lobcakers are smooth or rough; Furning from them on metal It turns out smooth as it were forged or matte, grungy, soft.

Purpinners (Poorbirds) - Chekani with a round, spherical head. Serve for an inquallation (lifting) of semicircular forms with an insane chasing or to obtain a wasometric texture when working from the front side.

Bobs, or crimping Chekak, are similar incomes, but with oblong, oval, legitur-shaped battle.

Tubes - Chekani, the works parts of which have a concave, semi-shaped surface of various diameters and depths. On metal form a convex spherical imprint - as if imitation of grain.

Pictures of the checks - in shape resemble lobckers, but give picturesque prints: lattices, stripes, dish, stroke, etc. are used when finished to give appropriate textures, processing backgrounds, etc. In fig. 5 shows a fragment trimmed with a pattern of chasane.

Special checks are used for narrowly special purposes, such as boots - to obtain sublinks on the relief, or the rope, - whose imprint, repeated repeatedly, gives the illusion of the twisted cord and others.

Figured checks, or punches, - on their working part of the engraving technology, fragments of the ornament (curls, sheets, flowers, sockets) or letters and numbers are made. Ancient Russian chasokers also used pansons with the image of hands, eyes, etc., which greatly facilitated and accelerated the chasing of facial, religious images.

Seshchi - Cecains, sharply sharpened, like chisels with a flat and semicircular blade; Apply to the background of the background with openwork works from the sheet.

The listed groups of CheKANs differ also in size and thickness. So, for minor jewelry works, it is used to be calculated, discharged from thin steel rods with a cross section of 3-4 mm. For conventional (medium) works, the thickness (in the middle) is used to 6-8 mm, and with large-scale decolation, decorative compositions with large forms, the thickness of the check reaches 15-20 mm and more. Such large checks are kept in a fist (like chisel). Sometimes wooden checks are used for the inqualing of high large forms.

Fig. 3. Academic work performed by RA Skhodnik

Fig. 4. Fragment made by consumable

Production of checks. Usually the checks are taken away from the steel bar; With the help of files, they are lying and attached to the desired form of the working surface (battle). Material for the manufacture of checks can serve as any tool steel; Most of the steel grades U7 and U8 are most common.

After the manufacture of Chekan, its working end (fight) is hardened and released. To do this, it is captured by ticks and evenly heated the battle to bright red riding (which corresponds to 750 - 850 s), after which they quickly lower in water for cooling. This operation must be done as quickly as possible, since cooling should occur within 2-3 s. The tempered Checkan becomes very solid and fragile.

To reduce the brittleness and eliminate the internal stresses, the tempering, the vacation is applied. Vacation softens the hardening action. For this, the tempered end of the check is grinning with a skin and heat up to a temperature of from 200 to 300 ° C. Starting with the pace-at / ry 220 ° C in the ground end of the Chekan, thin ENA of iron oxides, giving it various colors - from light-o-yellow (220 ° C) to blue (300 ° C), is the so-called colors.

walking. With the chasing of solid metals, the checkan is separated to the yellow-colored soft metals - to it.

The hardness of the working end in Chekanov after quenching and the appropriate vacation ranges from 7 to 12 (by Rockwell) depending on the nature of the work.

With a chasing of bulk, hollow products (vessels, sculptures, etc.) for the inquallation of individual sections of the form from the inside, long curved mines are used, the so-called "hooks" and "ratchet". They are massive steel rods curved at right angles. The working ends of the hooks are made that are flatter and rounded, then narrower and sharp, but still dull, so as not to break through the metal. The same forms and the combat ends "Prelight".

In addition to Chekanov, a hammer is used in the workshop. Modern, the specific shape of the chased hammer was developed in the process of centuries-old improvement and selection. On the one hand, it has a flat surface (square or round in the outlines) - for applying a bending of the check, and on the other hand, a spherical or semicircular end - for the deposit of recesses in the sheet metal. A feature of chased hammers is also a special form of their handles and nozzle. The handle is slightly flat, curved and thickened to the end. This form is easily and convenient to fall into the palm and does not tire the hand with many hours of continuous operation.

Fig. 5. Fragment, trimmed with drawdowed chashan

Technology Chacking

Preparation of drawing. For the production of chasing from a sheet, first of all prepare a drawing, made on paper in a natural value (template), in a linear (contour) manner, without shadows and with small fields for gluing it to metal.

To perform the drawing on the subject, it is scanned on paper: entirely - for simple forms that have one radius of curvature (cone, cylinder), to which paper is easily superimposed, or in parts - for spherical and complex profiled forms that have several radius of curvature. On such products, the imposition and combination of the pattern made on a flat sheet of paper, with a complex profiled surface of the product may be (conditionally) achieved only in small sections of the form with a greater or less paper deformation. Such products before applying the drawing are pre-locked and the drawing is translated on them in parts (fragmentary).

Preparation of plaques. Based on the size and configuration of the drawing from the sheet metal, the rectangular plates ^ with such a calculation so that the entire picture is free to be located and a small free edge of 30-40 mm wide remained around. This edge is needed for a stronger deterioration of plaques on the resin in the process of chasing, especially when the high relamp is traversed from the edges. With a chasing at the very edge, the plaque usually bounces back from the resin (especially from solid) and it has to be redesigned again.

Sliced \u200b\u200bto the size of a plaque with a wooden hammer align on the stove and pliers slightly bend the edges and corners. Thus prepared sheet blank is stronger than the resin.

Ground. Thanks to the pump, the plaque is firmly fixed, which is necessary when working. In addition, the fingerprint from the beacon is obtained clear and certain. Special boards or boxes are used for the ridges of flat chasing, the bottom of which is made of thick tesa (20-30 mm thick). Of the thinner planks from all four sides, a low side of the shallow box is nourished. Its to the edges are filled in advance with a welded and preheated resin, which is given to cool and harden. The size of the box must be slightly exceeding the size of the plaques so that a free field of resin is left from the edge of the flax to the walls of the box. The depth of the drawer should also correspond to the elevation of the relief. The higher the relief, the deeper must be a box.

Then a soldering lamp or a flame of a gas burner warms up the upper layer of resin, slightly stirring and moving it with a scraper. When the upper resin layer is well warm up, the plaque is placed on it, following it, so that it is located at the same distance from the edges of the box and did not sink deep into the resin. In addition, it is very important that the air does not hit the plaque and it would prevent the entire plane. Then she gives to cool.

Volumetric forms are glasses, vases, round sculptures, as well as deep bas-relief and burning forms minted, filling them with a resin. For this, the resin is heated and poured into the cavity of the surround forms, following the air there is no air and no emptiness formed. In case of chasing, it leads to a difficultly corrected marriage, since the metal under the blows of the check in voids fails, and sometimes breaks through.

As a support for bulk chasing, special bowlers are used, extruded in the form of a hemisphere of sheet steel and filled with preheated resin slightly above the edge (slide). On such a bowler, while the resin did not quite froze, but already thickened, prepared a place for the product being processed. For this, the hot and still viscous resin is covered with wet paper or cloth, and on top are put to be chasing the volumetric item (filled with a resin) and slightly pressed it into the resin. A rag or paper does not allow the resin to stick to the object, and the bowel is formed (imprint), exactly corresponding to its configuration, in such a tackle, the object is well and firmly hold back in the process of chasing, it is easy to remove, it is easy to dump.

Under the bowler with a chasing is placed a special rings in the form of a ring, made of rubber or rolled from trimming belts.

Translation of drawing. On a stepped plaque or volume transferred preparations. To do this, the metal surface is slightly covered with watercolor Belils and Figure 44 Ornamental grille: Through the Copying Boof - the drawing translated through the copying Magu is translated with paper drawing; Right - drawing, treated with a consumable (Fig. 44, left). The finished drawing on the metal is closed with nitroloma so that it does not erase when working. However, the drawing translated through the copy-ache is still a little durable and with a chasing of responsible works (large multifigure compositions, portraits, etc.) it is better to use the old tested reception - the canafarian. For this, the pattern is attached to the metal by means of plasticine (or wax) or gluate with soap solution, and then a special chackan - a canfarynik penetrate the drawing along the contours of the dots forming dotted lines, well noticeable after removing the paper.

Kanfarius must be easily, but confidently, so that every point from the blow of the canafarnica would be well noticeable, but it would not pierce metal deeply. Necessary deep canafaria is almost impossible to withdraw in the process of all subsequent chasing, and its traces are not always desirable on the finished product. Small drawing canphant sharp checkman, stinging points often (close to each other). A large drawing is applied by a blunt canafaric, a rare dotted line. The drawing after a skillful, neat canfark is saved and can be reused.

Return and lower background. The process of chasing is usually starting with a scanfarthamy pattern or consumption. By selecting the width of the width of the zoom-consumor, they pass along all the patterns of the pattern, connecting the points of the canafarnica into one solid line and deepen all the contours. For minor jewelry works, acute consumables, giving clear narrow touches, for large chasing, on the contrary, are stupid, wide consumables. With very large works, the stroke sometimes makes not even a consumable, but by the bobby. Moreover, for an even greater width of the rifle, the bobbinets put across and spend the lines with its wide side. After the spending, the drawing becomes clearly visible with the facial, and from the opposite side (Fig. 44, right).

The next operation is lowering the background around the drawing with more or less flat checks (bulk), which "removes" output. For this, the check is kept somewhat obliquely towards the pattern and, while maintaining the wall formed by the drawing consumility, align the opposite, facing the background. Lowering the background is to detect relief. The drawing begins to clearly perform, slightly towering over the precipitated background. This ends the first stage of the chasing. The metallic plate by this time has already time to join-Xia and requires further annealing processing (recrystallization).

Annealing. For annealing, the chasing is removed from the resin, heating it with a soldering lamp, after which it is easily separated. Capturing the plane by ticks for the edge, it is heated to dark red cagid. In the process of heating, the metal is ignited and the viscosity and plasticity again acquires. At the same time, the resin from the reverse side burns and the remaining dust is easily removed by crawling, bleaching and washing. The billet becomes completely clean and after drying again enters further processing.

Annealing of precious, colored and ferrous metals and alloys does not represent difficulties. Once the resin burns and the metal will begin to blush weakly, the heating is stopped and the annealing process is completed. Some features have annealing aluminum and its alloys. The recrystallization process of aluminum begins at 100 ° C, i.e. long before the start of red cation (glow). At the same time, the temperature ranges of red cation and melting at aluminum are very close. If the aluminum heat is hot, then it melts and the work started collapses. Therefore, with annealing of aluminum and its alloys (dural), the plate is slightly heated and the temperature of recrystallization is judged by the blackening (charging) of the soap, which is pre-drawn strips on the aluminum billet to be annealing.

After annealing, the aluminum plate was washed in a heated solution of two-dimensional soda or caustic soda.

Plicing relief. This operation lies in the further rise of the relief (if provided for in the picture). The relief is detected from the opposite side on rubber or sand bags. At the same time, they strive to raise the relief is possible more accurate, in accordance with the pattern. They are trained in various checks (with small work) or just the back of the hammer (with large chasing). Sometimes the lifting is made higher than, with some reserve, with the calculation of subsequent refinement on the resin.

The necessary relief clarifications when it is not possible to obtain without resin, but this task is not placed. The clarity is achieved later, with the final chasing on the resin.

Secondary pumping and final refinement. The secondary pump is produced in the same way as the first, with the only difference, which is now pre-all the elbow cavity is filled with molten resin and only after its cooling and hardening, the chasing is treated on the box. If a resin hit the front surface of the relief to the front surface of the relief, then it was washed off with a cloth, wetted in kerosene, and wipe dry. The final level of relief is in the detailed elaboration of all forms, identifying their characteristic features and at the same time coented the details of the main, creating a common one-piece impression of the whole relief.

The texture of chased surfaces is playing a major role in the final finish; The combination of smooth, forged and matte (rough) elements of the relief helps with minor differences in the elevations of the relief to receive a large decorative effect. Significantly enriches the use of various patterns of increments that give individual areas of relief striped, lattice, pits or cellular texture. Finishing work, the consuming (sometimes sharp) is again used. As soon as captured strokes or squads, applied to them, emphasize this or that form.

Much attention is paid to the decoration of the background - they are doing something smooth, wrought, then matte, mothers and drawing. Sometimes his can-fighter, and sometimes completely boke (with a thin sheet) or pierced with a jigsaw (with a thicker sheet metal). The scratch of the background is carried out without removing the work with the resin, after its complete and final refinement. For space, special sections and fine chubs with direct and semicircular (sickle) work end are used, sharply sharpened. Propilovka is made by the jigsaw after removing from the resin and annealing to remove resin residues on the back of the chasing, which interferes with propipilovka. After the batch or propipilovka, the burrs are filled with appliances of various profiles. ! if the final work finish is used by a large number of diverse checks.

In fig. 45 shows silver brutal XVII century. From the State Weapon Chamber, which is a perfect sample of chased art. It is very skillfully skillfully and with great taste, all techniques of art chasing are used.

Fig. 6. Chackled Silver Bratina XVII in Moscow State Weapon Chamber

In addition to the main processes and the priority of their implementation, there is a wide variety in the sequence of work and receptions of the chasing. Depending on the specific conditions, material and tasks apply various technology options. For example, with accurate works requiring a lot of clarity and loyalty of forms and contours of the figure, they are applied as follows: the scanfarty pattern is thoroughly reduced and the sheet is immediately removed from the resin, they are ignited, whiten and pumpped inside out, i.e. the backward side. Giving the resin to harden, the relief is detected directly on the resin. The lines of the consuming are clearly visible from the inside, and the work is very accurate.

When lowering the relief on the resin, it turns out true and clean, fully corresponding to the intention, which cannot be achieved when the relief is made on sand or rubber, where the large metal section is lowered (which is then clarified with the pump). When lowering the relief on the resin, a strictly limited, a certain form of relief is lowered, only the one in which the Chekane is applied. In the future, the work is again reduced, once again clarify the forms and the height of the relief elevated from the offline and end the chasing of the texture and other receptions of the finish. Sometimes with complex works with multi-digur reliefs, a large number of plans, etc., the perencorating on the other side is produced several times until the desired result is achieved.

With large decorative work with a very high relief or with a chasing of the cores, the translation of the pattern is not on the front, but on the root side of the sheet (accordingly the drawing is prepared accordingly). Figure Cantphart right on the workbench board, without a runner ^ (in order to reduce the flow of time), then the sheet is treated, and again inside out (back to the top), give a resin to cool down (until thickening) and begin to dig the relief, lowering it down, deep into the resin . Works lead quickly until the resin has cooled and hardened. Minic in shapes are minted with large checks of a spherical form ("issuing") or directly by the revolving side of a large chased hammer, in which the sizes of the spherical end reaches 20-25 mm in diameter. Frozening the necessary relief, the plate is rebigured and finish with the usual order. There are other receptions of the chasing of flat objects.

Fig. 7. Silver Endova 1644 Moscow. State weapon chamber

Chacking of volumetric forms. The initial stages of the chasing on the volume (the canafaria and the flow rate of the figure) are produced in the same way as on the plane. Otherwise it is the case with the paint relief. The usual checks of raising the relief on volume form cannot and work lead with hooks or ratchets. The exceptions are very large vases and other volumetric forms, where there is enough space in the cavity of the form itself not only in order to deliver the chasen, but also swollen a hammer. Works with hooks behave as follows: The volumetric item is in the workbench, laying under it a bag with sand or zin under it. Then, putting the combat end of the hook in the cavity of the form, the relief current to be flipped is hammering with a hammer along the hook, and in this way lifting one or another element of the pattern. Repeating the operation repeatedly and every time moving the hook battle along the inner surface of the bulk form, gradually knock out the entire relief to the desired height. In fig. 7 shows silver endow, the relief on which is raised by hooks.

Work ratchet is carried out otherwise. It is clamped by a non-working end in the chalk vise, and the vessel is kept in the hand (Fig. 8); Then the working end of a ratchet inside the vessel on the plot, the relief of which should be lifted (squirrel), and strongly hit the ratchet hammer. She vibrates and with sufficient elastic force causes a blow, raising relief. Work with hooks and ratchets requires a big skill. It is especially difficult to knock out the relief on the vessels with a narrow throat, through which you can not see where the ratchet or hook battle is scheduled. In this case, the work lead to the touch. The work is controlled only by the results, after each hit, according to that relief, which is obtained on the surface of the vessel outside, and the ratchet is moving, configured in the previous or incorrectly raised.

If the relief on the volume subject must be low, it is advisable to perform it on the plane (on the scan), and then ready to bent over the form of the item and attach. For this, the relief is minted by the usual technique, and then carefully bend it with hands or easy climbing with a wooden hammer (Cyanka). You can select the following types of chased work, differing in their technology and give a different artistic effect.

Plane (two-dimensional) chased works made by the spending. Return can be performed with both facial and reverse side. In the first case, the products are somewhat reminiscent of engraved. Frequently, modern artists are used with the extension consumption (Fig. 9).

Restage with spacing or pumping background. It is very simple and at the same time spectacular species of metal processing, creating lightweight, openwork metal lace. It has many examples in Russian decorative art made of sheet iron, copper, silver and gold (Fig. 10).

Fig. 8. Processing product ratchet

Fig. 9. Checked dish (copper)

Fig. 10. Copper Ombrella

Checking without patterns (not visual). Putting the texture by Pu-rosher, a bobbyman or patterns.

Return with lower background. This technique is widespread in the past. It is used for jewelry and various decorative products.

Relief with easy-to-paint relief with inside. The expense in this case is not done with a monotonous line, but alive, just as a skillful drawer draws a pencil - that is easy, it is juicy and wide. In this case, the line becomes dense and continuous, it goes into separate fast strokes.

Relief chasing with complete surface treatment of different heights and degrees of detail.

The chasenka without a minor of large generalized decorative reliefs from sheet aluminum, iron and copper is a modern reception (Fig. 11).

Chacking of bulk products of sculptural type (Fig. 12).

In modern conditions, artists use a chasing for processing various decorative objects - dishes, vases, wall plates, panels, etc., as well as for jewelry - bracelets, chestrooms, buckles of belts, suspension, etc.

Chasing on casting, or frown

Changing casting, or obron, applies in cases where it is necessary to obtain a particularly clear and clear chased shape. Minimize the castings obtained during casting to earthmams.

Fig. 12. Cup "Rooster" XV century. Germany Modern work

Modern, new types of casting (chill, accurate) chasing do not fuck, as castings are very accurate and clear.

Tools and devices for casting chasing are almost the same as for leaf chasing, with the exception of hooks and cracks that do not apply here. The difference lies only in a more solid hardening of the working ends of the checks, especially when the cast iron chasing and casting brass, as well as some bronze and silumin.

To fasten the castings during the chasing, they also use the resin, -cline castings are sculpted on drawers or boards, small volumetric parts minimize on the kittelet. Small jewelry (medals, decorations) are fixed on rosin.

Large parts hold in vice, while under. Sponges under-lay leaf lead or wooden strips, so as not to damage the surface of the casting. Press the casting in the vice should be very careful not to minimize its shape, especially the hollow and thin-walled, which, with an inaccurate handling, it makes easily and forms cracks.

Very large, heavy and bulky castings minimize on the workshop or right on the floor of the workshop (for example, bronze monuments). Casting, subject to chasing, is primarily purified from the molding mixture using rapid machines or manually. Then ignited to dark red crown, bleach, washed and dried. Anneaped parts are easier to double, but can be minted without annealing.

Casting casting starts with elimination of traces of the spruce. If the peel was supplied correctly, from the inner or back of the product, then its traces are easily removed by the filing with a file and boil. But in some cases, traces of the gateway are on the front side of the product; Then, first of all, we carefully cut through the metal cuts or chisels and the shape is cleaned respectively selected by the checks. Sometimes, if the otnik was supplied unsuccessfully, it is necessary to cut the relief or reproduce the missing elements of the ornament. On castings made in lumps, there is always a more or less noticeable oblast, in the joints of the junction of pieces it is also cut down and boil.

On the hollow castings of the complex shape (figure) there are often holes from the signs of rods. Such holes are drilled, into the resulting cylindrical openings are inserted on the cork threads and boil. The plugs are pulled out of the same material from which casting is made. It is best for this purpose to use large sprues (or specially cast cylindrical blanks). The plugs made from identical material, after their grover-ki and finishing the figures become completely invisible.

In the chasing often, it is often necessary to correct the marriage of casting: shells, non-obligs, as well as highlights, obcomments and other defects that are obtained either from the skew of the whole, or from the sanding of the earthen form, or in the place of chosen from the impact and blurring the metal jet when filling the forms. In these cases, there are noticeable protrusions on castings. They are also neatly (in order to not capture the main form) cut into sch and bumping-baths. First rough shells with a large grain to tighten or compose a defect, restore the basic shape, and then are already separated by smooth or matte checks, depending on the nature and texture of the entire relief and in accordance with the idea of \u200b\u200bthe author (sculptor).

With the final casting chasing, it is necessary to carefully select the checks in the form of combat and its invoice, so that it is possible to better express the character of the pictured: juiciness of the fruit or tenderness of the petals and the composition of the colors, the softness of the folds of the fabric and fur fluffiness or, on the contrary, the rigidity and hardness of the stone, elasticity and hardness The brilliance of the metal, etc. For this purpose, except for various checks, files, rheiffs and noodles, as well as shabra and spurled to get smooth, polished surfaces.

In fig. 13 Dan fragment of the bronze lattice from the Assumption Cathedral of the Moscow Kremlin, which is an example of high chasing chasing on casting.

Currently, borrowers (with a flexible hose) with a set of all sorts of steel and abrasive shag, which greatly facilitate the work of the processing and finishing of casting, are widely used. Sharms easily remove various influx, growths, traces of sprues; At the same time, the surfaces give a diverse texture, which is impossible to reach the checks.

To obtain solid, uniform, matte, velvety surfaces, we use processing sandblasting plants with different grains of sand. Coarse sand gives beautiful rough finishes; The fine sand gives the surface the finest matte velvety.

In case of a coquiscation of large monumental casting, pneumatic hammers are widely used. Hammers are driven by compressed air, which automatically, alternately fed into the upper, then in the lower cavity of the hammer and with force moves the plunger. There are various types of ivolochkov, characterized by their characteristics (mass, dimensions, the number of blows per minute, length of the stroke, etc.). Existing hammer designs allow you to quickly and easily replace the to-weht. The working tool - chisel, crithersselleseels or checkers - insert into the tract pressed into the hammer barrel, with the help of a special shank. Pneumatic hammers perform various preparatory operations - stump of sprues and growths, tightening the shells, as well as the application of gross textures, etc.

Fig. 13. Bronze chased lattice from the Assumption Cathedral of the Moscow Kremlin (fragment)

For lifting and carrying heavy castings, bridge and rotary lifting cranes are used, et al. The purification of large casting from the molding ground is produced by hydromonitifers (water jet).

Usually, this type of artwork is divided into chasing on casting and shelter on sheet metal.

Workplace

The desktop is better to put near the window so that the sun's rays fell on the left side. For artificial lighting, a daylight lamp is used or with a matte coating, with a capacity of 75-100 W. So that it does not interfere and did not occupy a lot of space on the table, it is located aside, at a distance of 50-70 cm from the lid. Bringing the deep shadow on the product will not appear if the main light also includes.

The table is choosing most often wooden, with a thick lid. Its dimensions depend on the products that the wizard is most often. To muffle the sound from shocks, under the feet of the table are placed gaskets from dense rubber. But at the same time its stability should not deteriorate. Chair with a back or stool is selected by the wizard and the size of the table.

The workplace will be comfortable, if you equip it with racks and drawers, it should be placed so that you can reach them without getting up. The order in the instruments will help save time on their searches. After the work tool is completed, it should be immediately put in place. It is necessary to bring this habit to automatism and not think about the work on where what lies.

After the end of work from the table, it is necessary to mix all chips and dust, and the room is to ventilate.

Optional equipment

In the equipment of the workbench additionally it is necessary to include small parallel vices with an odor. Fastening is better to choose a clamp that, if necessary, will allow you to quickly remove the vice from the table and release more space (Fig. 102).

Fig. 102. Tysochka clamps: 1 - sponge; 2 - screw with a handle; 3 - pen.

It is good to have a grinding machine with interchangeable discs, which can also be used for sharpening tools, and for fusion of the edges of the blanks. For sheet chasing, it is necessary to prepare a substrate for the product. For it, the resin is most often used. For cooking and spill fillers, as well as for pumping, special tools are used for pumping: containers, a tile with a closed spiral for cooking resin, scrapers and wooden boxes of different sizes in which the substrate is stacked.

For the subsequent annealing plate from the substrate, you will need a heating device (it is convenient to use a soldering lamp), blacksmith mites and mittens to hold the product. For chemical processing, a set of special tanks and baths, as well as drawers for reagent storage and protective rubber gloves. Drying of the processed plates is carried out in wooden boxes filled with well-absorbing moisture materials.

Above the table at which chemical solutions are prepared, as well as over the heating device, it is necessary to set the exhaust.

After the end of the processing, a flat chasing is often aligned. This uses test plates with a smooth and smooth metal, stone or wood surface. Any massive subject is also suitable, which allows you to perform this operation.

Since in the process of making the chasing, the product passes a few stages, then unnecessary tools should not accumulate in the workplace. In the conditions of a regular apartment, as a rule, there is no possibility to post a few more tables for operations on the processing of the finished product, so the working surface of the table is better to arrange so that unnecessary objects are such as vise, drawers for the substrate, etc. - it was easy Remove. For the same reason, it is not recommended to engage in several products at once.

Instruments

To perform high-quality chased operations, there are coins of various shapes and from different material, special hammers and other tools related to a blacksmith and plumbing.

Chekany

This is the main working tool with which all processing is conducted. The masters are used by the checks of a special form, allowing to extinguish the side vibration and ensuring accurate distribution of impact energy. In the middle part, they are noticeably thicker than at the ends. Their length is 120-180 mm (Fig. 103).

Fig. 103. Checkan: A - Osto; b - a combat end; B - section is the island.

For some special works, the checks may be longer, curved shape.

The coching cable (Fig. 103, a) is usually eight-marched. With this form, the position of the working part can be controlled by hand during the chasing, without looking at the tool itself. The core is made under the parameters of the human hand.

The combat end (Fig. 103, b) may have a different shape and dimensions that are determined by the assignment of the tool and the value of the processed part. The wizard can make himself the required form of an eight-marginal or round bar, self-revealed independently or pulling out the work end on the machine. After that, it must be hardening and released to the blue color of running.

Depending on the form of the combat part and the type of work performed, several varieties of checkers differ. Among them, the main group is allocated to which Kanfarniki include consumables, bobs and bulk skishers (Fig. 104).

Fig. 104. Main types of Chekanov: A - consumables; b - bobbies; in - shuthesterns; g - pillow; D - Kanfarnik; E - boot; f - figured checkers; Z - Iron; And - tube.

With their help, the main part of the work on drawing and the creation of relief is performed.

Kanfarnik

In the form of the working part, it resembles a stupid sewing needle (Fig. 104, e). The canafarnik serves to knock out points on the metal and creating a relief rough background, often used in compositions (Fig. 105).

Fig. 105. Background created using a canafaric.

In addition, with its help, the paper pattern is transferred to the metal.

Consumables

In a different way, they are also called the bypass checks (Fig. 104, a). In the form of a combat end, they resemble a conventional screwdriver. The working line for better slip is made slightly dull. They are used to conduct clear solid lines along the contour of the pattern. The softer line is formed from a wider consuming.

For curves and rounded lines, semicircular consumables are used with different radius of curvature battle. The more it is rounded, the harder it is to lead the chasen on the surface. In this case, care caution and work with single blows so as not to get individual prints.

Semicircular and direct consumables are made in pairs, so as not to disturb the integrity of the line during the transition from direct to the curve.

Similar to flow consumables, but with sharply sharpened flat or semicircular blades, called SCHs. They are used to arm a leaf with openwork work and when cutting complex contours (instead of chisel).

Boboshniks

So called the incomes with a convex oval combat part (Fig. 104, b). Another name of this group is common checks (ignition) comes from the ancient Russian word "round", that is, round. Mainly, they are used to create convex parts of embossed compositions. The form of the working part does not have to be oval, it is made and rectangular, but with rounded corners, so as not to damage the material when the relief is painted.

Loszhetniki

They serve to equalize the front surface after running the relief, lowering the background and other operations (Fig. 104, B). The surface of the fight can be completely smooth or with small roughness to create a matte background.

In order for the surface of the product, there were no traces of the working part of the check, the angles are slightly rounded. With the help of bulk, you can simulate the texture of a wrought or cast product.

To obtain a quality product, it is necessary to observe the sequence when using the incomplete groups of the group and during the transition from one group to another. If you need to make a deep paint, then first use the largest consumables, and then, for more detailed finishes, less deep, etc. are applied.

First of all, the processing of consumables is carried out, then the bulbs and last bulk shops. This sequence is presented in Fig. 106.

Fig. 106. Sequential transition from one checan to another.

The species of special checks are much larger than the main. They produce final finishing of the product.

Purpinte

Changes with the working surface of a spherical form are called poultry (purples) (Fig. 104, d). They are used for pumping pits or semicard relief shapes. Purples of different diameters are used to obtain deepends of different height and size.

Crimple

Combat ends are concave spheres of various diameters and depths. They stroke the spheres from the pillow. For this purpose, the crimping is taken by several large sizes. When working it makes circular movements by hand to prevent dents. Crimples are like straight (with spherical pressure) and oblique (with a presses in the form of a hemisphere). The latter are used to streak the twisted cord.

Sapoch

When it is necessary to read the drawing of a convex form or underdit (squeeze out the line of drawing) the relief, the so-called bootball is used (Fig. 104, E) - the curved shape. It refers to special checks. To work with it requires a lot of experience.

Iron

Another beken with a funny name "Iron", or "Davlic", is used to stroke (pushing) drawing when working with high relief products (Fig. 104, h).

Punns

Figured checks of the punches (Fig. 104, g) apply if it is necessary to minimize a large number of small patterns of the pattern. On their working surface, while it is not yet hardened, a small drawing or a detail of the ornament is engraving. A packing of the finished pattern on the product produce strong single blows, evenly pressing the operating part to the surface. To make it easier to focus Puinson during packing, the drawing is strictly on the battle axis.

Sichki

When performing openwork works, sections are used - sheeps with a pointed working surface. They are divided into semicircular, which in shape (but not at sharpening) resemble a knife and are used to extend curves of lines, and direct, more similar to consumables, with which straight lines are cut.

Tubes

To perform a pattern in the form of small convex balls (grains), the check tubes are used, which has a concave hemispherical shape (Fig. 104, and). The recesses can be different diameters and depths.

Hook and ratchet

These curved cecans are used when working with bulk products. Their martial ends are not made in the form of consumables and bulkware, as they are intended only to create a common relief. Unlike a ratchet, the hook has two working end, one of which is pointed and used for small parts of the drawing, and the other is somewhat rounded.

The dimensions of these tools depend on the product being processed. However, it is not recommended to make them from the steel section more than 16 mm, since when the hammer hit the hammer, the hook and ratchet must vibrate well.

A few words about the size of the above tools. For jewelry work, small (diameter 3-4 mm) of the incomes are used, for the work of the mid-size - about 6-8 mm in diameter and more. For large compositions, wooden checks are sometimes used, which are kept in a fist, like chisel (Fig. 107).

Fig. 107. Wooden checks.

You can store the checks both in the boxes made specifically for this purpose, and in a high glass, but in this case, be sure to work up. Otherwise, the search for the desired tool will be difficult.

Hammers

In the form, the chased hammers differ significantly from ordinary, plumbing. The head of such hammers has two boosters: on the one hand, flat or slightly curved and significantly wider, on the other - rounded (Fig. 108).

Fig. 108. Hammer for chasing.

At the moment of impact, all the energy and attention are concentrated on the working surface of the Chekane. The second board can serve as a pillow.

For work, a chancener must have at least three hammers: at 100, 150-200 and 400 g.

Handle hammer, also a special form, is performed from solid wood. The cross section in the area of \u200b\u200bthe neck is round, when approaching the end smoothly goes into elliptical. The dimensions of the hammer are chosen so that the handle does not interfere with when working, but the blow would be achieved quite strong. The head is planted on the handle so that it is at an angle of 90 ° to the working surface (Fig. 109).

Fig. 109. The position of the hammer handle.

Wooden hammers made of durable varieties of wood, such as oak or birch (Fig. 110), are used to work with soft metals.

Fig. 110. Wooden hammers.

With their help, softer lines are carried out, since the impact force is much smaller with such a hammer.

Other tools

At various stages of working with workpiece and chasing, other plumbing tools will be needed. Among them, it is necessary to especially mention those that the image is transferred from paper on metal: kerner, metal circuit, a ruler, etc. Supports and scissors for metal, files, noodles, rashpille, etc. For the separation of the chasing from casting during annealing, blacksmiths are used Pliers. If they were not at hand, you can use pliers.

Material

For chased work, sheet metal is used, the thickness of which depends on the material and the height of the relief. The most often used metal thickness up to 1 mm.

The main property that determines the suitability of the metal to perform the chasing on it is its plasticity. This property has copper and its alloys, aluminum. They are most often used to make high-relief chasing.

Red copper

This metal is very highly appreciated among masters and lovers due to their high plasticity. After annealing, it easily restores the form. From copper it is easy to make a thin (no more than 0.05 mm) foil. With a chasing from a thicker foil, you can get a high relief.

Copper is well polished and grinding, has high corrosion resistance. Processing of products from copper chemical solutions allows you to get different shades of color.

The disadvantages of red copper are bad sharpness and fast oxidation in the open air, as a result of which it is impossible to keep the original glitter of products.

Brass

This alloy of copper with zinc was known in ancient times. It is better than copper, cuts and polishes, is well covered with nickel, silver, gold. Brass is inferior to copper in plasticity, but has a greater hardness.

For chasing, it is better to take brands of brand of brass with a high content of copper (L62, L68, L80). Such alloys are called TOMPAKA. They are better than flat relief compositions.

In the process of chasing, the strength of the sheet increases due to the formation of a label, and the plasticity falls. To remove it, the brass is warmed up to a temperature of 600-700 ° C.

Cracks may appear from long-term storage in a cold and wet place. To avoid this, prolonged calcination at a temperature of 200-300 ° C.

Aluminum

It is very good for beginners of chasters. Aluminum foil for a long time saves high plasticity, does not require heat treatment. This material allows for a long time to work on one ornament, correcting errors.

It is easy to minimize with an impurity content of up to 2%. Marks with a large number of impurities are less plastic, so they are recommended to be used for chasing with a low relief or for contour and openwork spontaneous works.

Nickel alloys

Melchior and nezilber are most often used from these alloys. The copper content in them is quite high (81% and 65%, respectively), so they have a good plasticity.

When treatment with sodium hyposphate solutions and acetic lead, give a variety of shades. The surface is well polished and has a number of features that can be beneficial in combination with color.

Black metals

For the chasing, a pre-annealed and treated steel with low carbon content is a decopyr, as well as riveted before and after annealing - twice decopyr.

Compared to copper, it is not so soft and in the process of the chasing is quickly stuck. It is omitted at a temperature of 700-760 ° C.

Small decorative products are made from the decoir, the high relief is disappeared only on rather large items. When finishing and applying the texture, the material acquires special beauty.

Roofing and stainless steel

Sheet, or roofing, steel can be used for chasing of simple ornamental products. It allows you to conduct contour chasens with the lowering of the background and the application of the invitation. The masters of ancient Russia created openwork chasens from this material with the spacing background.

Stainless (chromonic) steel is often used to create large ornamental products. Because of the great difficulty of the chasing, it is practically no applied when creating small works.

For creating beautiful chasing in the past, precious metals were often used - gold, silver, etc. Now this art is not appreciated is not so high. Most chasing under gold is made on a brass resembling it, silver is replaced by Melchior and nickel alloys similar to it. Noble metals are used mainly to create small jewelry.

The chasing was made in ancient times and such products were such expensive that only rich could afford such a luxury. Now in our time not only everyone can buy it, but also to do at home. How? This will be discussed in our article. We will look at the Master Class of Chacking from Foil with their own hands, which can be hung or put at home. As a gift, she is also perfect for a gift. To begin with, we consider a simple option to create a chasing.

We start with simple

In any store you can always buy ready-made sets for creativity. But it is much more interesting to do everything from beginning to end to the very end, and also invent a drawing. You only need efforts and patience.

Materials will be needed:

- foil sheet or aluminum bank;

- substrate under the foil sheet. Important: The thickness of the foil sheet, the softer there should be a substrate. The substrate is suitable felt, rubber;

- to apply the drawing, you will need a tool. As it can serve a wand for sushi, a brush (its solid tip), not a writing handle and so on;

- stencil, pattern pattern, and you can come up with yourself;

- scissors;

- line.

Let's start making a chasing. Take the bank. Both the bottom cut off. Now cut the jar from one edge and straighten up to get a sheet. Now the line is racing the edges and cut them. The option of using a foil sheet is not excluded.

Now put the material face down to the substrate. The drawing then turns out in the mirror image. Now put stencil on the sheet and use the tool to press the picture. You can urge either a solid line or intermittent. Now in this way you can make the frame.

Gift native and loved ones

Each child at least once, but gave her parents to her parents made by their own hands. Undoubtedly, parents were happy, seeing a small surprise from her baby. One of the options for a gift can be a chacon for dad. Today we will consider it in stages, how can you make a cute "machine."

We need:

- foil;

- cardboard;

- tool (tassel, wand for sushi);

- pattern or stencil;

- the substrate (it may be an album or felt).

Perhaps, let's start. Put the album on it foil, and then the template as follows:

Exactly by contour we supply our drawing tool.

After spent lines, we remove the template and the following.

Now with the help of the same tool we make points around the typewriter.

Cover now separate parts of the machine. You can start with the windows.

Turn the foil now and circle the same detail along the contour.

If you turn the work, then what should happen:

We are then doing the rest of the car according to the same principle.

Now we turn the foil and supply over the office and in the details of the machine tool again.

As a result, you get such a wonderful present for your parents.

Now the opposite side is put on the table our work. Take cardboard.

Then impose cardboard on foil.

The process of producing a pattern that is obtained when knocking on a sheet of metal. The chasonka is one of the types of applied art. The chasing is used in the manufacture of kitchen utensils, paintings, products from precious metals. The relief on the metal is performed when the checks and hammers are exposed. They are performed from metal and wood.

Checking - handmade

The drawing is minted on a metal sheet, pre-laying it on a birch or lime ridge. In addition to them, rubber, bag with sand apply as a substrate. Some masters are applied from lead.

By the way, without a chasing, there were no mint yards on which coins were minted. They are made of metal with a thickness of more than 1 mm. To obtain high-quality and accurate reliefs, special presss are used, with a pre-installed stamp that draws and the necessary inscriptions are applied. The press ensures the force necessary for the blow, the deforming surface to the required state.

By the way, regardless of the type of chasing, it is completed.

The main types of Checkancay

There are several types of chasing - bulk and flat. Volumetric is distinguished by a high form of relief. Flat, on the contrary, has a low relief. Each of these species has a number of advantages. Undoubtedly, the volumetric relief looks more effectively, in fact, it is 3D technologies implemented in metal, for example, the volume can be attributed to the volume of pipes. On the other hand, a flat chasing for metal wears more openwork and this can be considered a sign of high artistic style.

Most often, the wizard uses sheet material with a thickness of 0.4 to 1 mm. For work on the execution of volumetric relief, materials are used with greater thickness, for example, copper, with a thickness of about 2 mm.

Jewelers in their work use gold and silver alloys. Slightly less they operate with red copper and alloys based on it.

Red copper is known since ancient times. It has a plasticity required by viscosity, but the main thing is that this material is able to restore its plastic properties on heat treatment. Copper is easy to minimize, she can be given the most different shape. On its surface it is possible, without special difficulties to perform a high paint. It is well polished and polished, but the products made of copper are quickly losing the applied shine.

Copper and alloys based on it differs high resistance to corrosion. They can be stored in air without much difficulties. These and some other characteristics allowed to use copper as a basic material for performing volumetric and flat chasing.

In addition to copper, materials such as bronze, brass and some others are widely used.

Aluminum is quite easily subjected to a chasing, but working with it requires a sufficient share of caution. Metal has a low melting point and precisely for this it is necessary to monitor in the process of heat treatment.

When choosing a metal for a chasing, it is necessary to take into account that it should not be stratified, there should be no defects on the surface, for example, spots, cracks, etc.

Before starting work, metal, regardless of the brand is subjected to heat treatment - annealing. To perform this operation, either traditional soldering lamps, or muffle furnaces are used. Copper is annealed at a temperature of from 650 to 700 degrees, brass 620 - 650, steel 600 - 650. For cooling, various media is used, for example, cold water is used for cooling.

The main working body, with the help of which the chasing is performed is the checks. They are performed using forging. They are made in the form of rods of different sections and having a length from 12 to 17 cm.

In the work, the check is held in the left hand, while the elbow is on the weight. This guarantees the freedom of movement of the hand. Checkan hold in such a way that he always spoke back, so that the battlement was slightly raised. As shots are applied by a hammer for a chasing, which the master holds in the other hand, the tool moves forward.

Technological process

Work on the implementation of the chasing begins with the preparation of the pattern, which is performed in a variety. The drawing must be performed in the contour manner, that is, items must be depicted without shadows. On the sheet it is necessary to leave the fields needed to fix it on the metal.

To transfer the pattern, on the processing item performed its scan on paper. Based on the latter, the outline is cut out of the metal. Its size should be a bit, 3 to 4 cm, exceed the area of \u200b\u200bthe image applied on paper. This metal strip is needed for mounting the metal in the workplace. By the way, to enhance the fixation of the metal sheet, the resin is used.

Diverse types of products

The chasing is widely used in the production of products of different purposes, from metal sheets of different brands. It is widely used when making buildings inside, and outside. This operation is used in the production of metal dishes, decrative maleels, decorations.

When creating masters, special techniques are used, for example, grape chasing. In this case, there are many secrets that are often transmitted from generation to generation.

In the workshops to perform chased work, paintings, interior elements are performed. In addition, some masters perform work in the manufacture of paintings, which consist of several layers, including those that consist of several metals. Such a combination gives the composition of the multicolor.

In the workshops on the implementation of the chasing, fragments are performed, which can be installed in furniture, made of both the array, and different types of panels.

A special kind of chasing is salaries for icons, except for drawings on their surface, precious stones are fixed.

For all the time, while there is a chasing, separate styles (Caucasian, East, etc.) have been developed. Modern masters apply all previously accumulated styles and at the same time develop their own.

Checking do it yourself

The chasonka, made by her own hands, will be a good interior decoration and will delight the eye for a long time.

To create a picture, the sheet of copper or aluminum is best fit. These materials possess all the necessary properties to create the desired patterns and paintings.

To perform the chasing, a beginner master will be required:

- copper or aluminum sheet;

- rubber sheet or plywood, which will serve as a substrate to perform the chasing;

- tool for performing contour and volumetric chasing;

- hammer, etc.

Of course, the work on obtaining an image on metal cannot be started without a working sketch.

Before starting work, it is necessary to prepare the main material, in particular, it is necessary to warm up the sheet of material and then give it to cool.

After analyzing the sketch, the future master should make a decision - which lines will be formed on the facial, which on the involving side.

All work starts with the front side of the sheet.