Selection of the furnace in the bath. Design furnace for baths - types and design features. The material from which the furnace is made

Bath procedures in our special post. So it happened historically. There are centuries, and traditions to bathe in the bath are not going anywhere. Many owners of houses, cottages and country sites plan to build a Russian bath or sauna. One of the main questions is the choice of the furnace, because this is the heart of the bath. We will have to take into account the mass of factors, to determine the material of the furnace, with a power, type of fuel, additional functions. To choose the right stove for the bath, you have to explore the question comprehensively.

Go for the purchase of unprepared - Home Errorwhich are making lovers of bath procedures. Second error - buying too cheap furnaces from ramless manufacturers. Probably, you should not explain that in this case you risk your own security. It is better to take a product from the company that has proven itself in the market. A vivid example - the domestic company "Teplodar" has been working since 1997, has its own design bureau, controls product quality at all stages of production. The company's online store offers a wide range of stoves for baths and saunas. Dealers and service centers are throughout the country.

№1. Criteria for choosing a stove for a bath

The choice of a reliable and durable furnace must be done before at the stage of its design. Such an approach will allow in advance to calculate the basic parameters of the equipment, organize the necessary foundation base, provide for the installation options for the furnace. At the same time, the main criteria when choosing are:

- type and constructive obstruction of the stove used type of fuel;

- power and performance, compliance with the specified parameters of the size of the steam and bath in general. Insufficient power leads to the work of equipment for wear. Too high productivity means quick heating of the room with insufficient temperatures of stones, which leads to an imbalance in the adoption of wellness procedures;

- the principle of operation of the furnace. Classic models require permanent maintenance. Long burning furnaces can be warm for 4-6 hours, without requiring your intervention;

- the presence of a water tank;

- the presence of a convection function;

- couple quality. The furnaces are equipped with open or closed heaters. In the first case, a lightweight, dry pairs are created in the steam, in the second - wet.

When choosing a kit, it is advisable to familiarize yourself with the instruction manual, pay attention to the safety of the model and its compliance with the requirements of the current standards. User feedback that has already bought the selected model will also help with the choice.

№2. Bath furnace design material

If in the distant times of the furnace did only brick, today they have an alternative - steel and cast iron products. As you could guess, everyone has its strengths and weaknesses, but there is something in common. The better the quality material was used, and the thicker walls got the oven, the longer it lasts.

Brick oven

Today it is becoming less and less popular. There are several reasons. The main - it is difficult to find a specialist who would correctly laid such a furnace. Yes, and in Russia, the ability to put a bath furnace was considered art, all the nuances were kept secret, and now find a worthy binder almost unreal.

Benefits:

- long keeps heat;

- heats up a large area;

- good fire safety;

- authenticity. If you want to steam in the real Russian bath, then build a brick oven.

disadvantages:

- the complexity of the construction, sometimes it is impossible to find a specialist;

- heavyweight. The middle stove weighs about 1200 kg, which means that it is necessary to prepare a reliable;

- high cost due to the need to pay for the work of a professional and create a foundation;

- easy. The brick oven will take a substantial part of the steam;

- long and hardly melts, but it is very hard for heat.

Also, experienced banknets note that to obtain a couple, it is necessary to spill to the stove with water, and the smell of wet brick is not very pleasant. Looks like a brick stove, of course, gorgeous, oh can be smelted and share a brick screen around the steel product.

Steel stoves

Are considered the most optimal option. Make the furnaces of their chromium steel, they were nicknamed "clean air", as they do not burn oxygen. Sold furnaces ready, special secret knowledge for successful installation do not require.

Benefits:

- ease of installation;

- low weight, so a separate foundation will not be required;

- compactness;

- simplicity;

- rapidize the room.

disadvantages:

Cast-iron stove

Popularity of pig-iron furnaces only slightly ahead of bricks. They also almost no one uses. The causes of mass, but also the advantages of such aggregates are fully, so think about the choice.

Benefits:

- high heat capacity and heat transfer;

- durability up to 40 years;

- simplicity;

- safety.

disadvantages:

- high weight, so you have to equip the foundation;

- high price;

- cast iron is a fragile material capable of cracking or split during transportation or significant mechanical loads.

It is worth mentioning even so-called. bourgehogsPrimitive designs with a pipe and a door. Of course, such equipment can be used, but still it is a relic of the past, which is inferior on functionality and safety with modern counterparts.

Number 3. Bath Furnace Power

The dimensions of the wage play a decisive role when choosing a product power. In order for the temperature inside the steam room is optimal for the body, the bath can not be pulled out. With excessive power, the air will be hot, and the stones are cold. If you choose a model that is insufficient for heating steam room, drowning the bath for a long time with the corresponding energy costs. At the same time, the deadline for the operation of the furnace will be significantly reduced. In general, the furnace must have optimal power and, preferably, the sufficient range of its regulation.

Method for calculating the required power as follows:

- calculate the volume of steam room. For example, for a room of 3 * 2 and the height of the ceilings 2.3 m, the volume will be 13.8 m 3;

- calculate heat loss with cold surfaces (windows, doors). We consider the area of \u200b\u200bthese surfaces and multiply it by 1.2, since each such square meter absorbs the heat required for heating 1.2 m 3 volume. Suppose, in the pair there is a window 0.5 * 0.8 m (area of \u200b\u200b0.4 m 2) and door 2 * 0.9 m (area of \u200b\u200b1.8 m 2). The total area of \u200b\u200bcold surfaces is 2.2 m 2. Increase the calculated volume is required by 2.2 * 1.2 \u003d 2.64 m 3;

- we summarize the obtained indicators. It turns out 16.44 m 3;

- we make a correction for the material of the bath. If the bath is a log, without (minimum heat insulation), then the result resulting is multiplied by 1.6. If the bath is inside, there is a layer of insulation (maximum thermal insulation), then a coefficient of 0.6 can be taken. Suppose our bath can not boast of high-quality thermal insulation, then 16.44 * 1.6 \u003d 18 m 3, it means that a furnace is needed by 18 kW. It is better to take with a reserve of 20%.

Power range. The ratio of minimum and maximum power, ideally, - 1:10. Such a furnace can work for 3 kW and 29 kW. Power in the furnaces is regulated in several ways:

- you can adjust the number of fuel supplied. Convenient for gas stoves, but not on firewood;

- restricting the number of incoming air. Option for firewood furnaces;

- emission of excess heat into the environment. Literally - open the door and steam room.

If the manufacturer does not indicate the power of the furnace, then it can be approximately calculated, multiplying the volume of the furnace by 0.5.

№4. What fuel does the oven work on?

Woodstocks

Firewood furnaces are a classic option for a Russian bath. With the help of similar models in the room, a special atmosphere of comfort and comfort is created. The furnaces are distinguished by practicality and durability, ease of use, and wood is affordable and widespread material. If in the region in the region with gasification and electricity, then firewood is the only option.

pros:

- no additional lodging of communications is required, there is no dependence on supplying companies;

- provide a wood-burning battle is simple enough. Possible purchase of a material or its independent billet;

- depending on preferences, you can purchase various types of firewood, differing in composition, performance, efficiency of use;

- nice fragrance of wood;

- a wide range of furnaces.

Minuses:

- will have to periodically clean it;

- when combustion of fuel, the ash is formed, which must be regularly removed from the ash bar and chimney;

- with the help of firewood heated the steam room more and longer than using alternative fuels;

- we will have to constantly throw firewood.

The result of the furnace of the wood furnace largely depends on the quality of firewood and even the skill of the expiratory.

Gas stoves

Gas-based bath furnaces have a greater mass and relevant dimensions, and their connection should be made with the involvement of qualified specialists. Setting such a design eliminates the owner from constant control of the flame level and firing lining. Main or balloon gas can be used.

pros:

- compactness. Unlike wood stoves, gas costs without fire and ash bar, so for suitable just right;

- no need to follow the presence of fuel. True, in the case of balloon gas, you must not forget to fill or change the cylinders;

- the indoor temperature can be monitored by changing the fuel supply intensity;

- do not clean from ash:

- operational heating of the room.

Minuses:

- the need to connect to, and here without attracting a specialist nowhere. If there are no gas in the region, there will have to use cylinders, and this is not entirely convenient;

- fire hazard gas furnaces is higher than alternative options.

When buying a gas stove carefully examine its technical passport. You can trust only the proven and proven manufacturers and shops - no private owners. Gas furnaces used better not to take, high risk that they work not entirely as it should.

Electric furnaces

Bath furnaces operating on electricity have no chimney. The advantage of such models is the absence of carbon monoxide, which eliminates the likelihood of combustion poisoning. The power of such equipment is selected, based on the size of the room, but the energy consumption of electrical furnaces is quite high. Today, electric furnaces are considered the most popular, presented in a wide range.

pros:

- compactness and low weight;

- fast and uniform heating;

- simplicity in management, flexible settings, functionality;

- no chimney, so do not have to build and clean anything;

- small cost;

- does not require connection to gas;

- fire safety.

Minuses:

When connected, make a separate grounding contour for the furnace.

There are still combined types of furnaces, such as gas and on firewood. Such a product will be overall, but almost universal.

№5. Location of firebox

Depending on the location of the furnace fireboxes:

- with extended firebox;

- with classic.

Extra long furnace Get furnaces that are mounted between the steam room and the pre-tribades. You can turn the oven from the pre-banner, which is positively affected by fire safety and convenience. The one who throws up the firewood will not interfere with those who are steaming, and dirt in the steam room will be less, and the microclimate in it is better. The usual firebox is located in the steam room.

№6. Para

Bannam furnaces are ordinary and with steam generator. What is the latter? And in order to provide the room with a sufficient number of steam when the furnace itself does not cope. The first sign of the real Russian bath is a dry and easy pair. Not all modern furnaces are capable of producing it in sufficient quantities.

Light steam is obtained at a temperature in a steam room 85 0 C. At the same time, the fine pairs are obtained when the water is heated to 500 0 s. With such a heating, the air temperature necessitates, and to the incredible limits, and in the end, it is possible to earn a burn. So that this did not happen, created furnaces with steam generator. It warms up much faster than stones and saturates the steam room with a steam, while the air temperature in it remains optimal.

pay attention to furnaces with convection. They provide optimal air exchange in the steam room. Due to the design of the heater and protective casing, the heating temperature is quickly aligned, the temperature of the cold and hot air masses occurs. In the furnaces without convection to create optimal conditions in the steam room required more time.

The furnace can be equipped with capacity for water heating. Capacity can be built-in or remote. The first option is suitable for a steam room, designed for 2-3 people, will provide them with a sufficient amount of hot water. Remote container is installed in the baths with high visiting intensity.

If there is a need to catch adjacent premises (pre-tribades, shower, changing room), then you can take a furnace with heat Exchange. As a rule, the combined heating principle is used. The steamer is heated by convection, and adjacent rooms get heat through the receipt of heated heat carrier on radiators.

№10. Form of the furnace

The form pays attention to the last place, and then consider it more from the point of view of the dimensions. It is worth noting that classical rectangular stoves in priority. They are more steady and warmed evenly, which you can not say about cylindrical models, the upper and lower parts of which are heated unequally.

Finally

Hasteless decisions taken without careful study of the issue may adversely affect the choice of the furnace and the subsequent operation of the bath. Planning a purchase, you should not trust advertising information and the arguments of sellers, often poorly dismantling in their products. After studying all the details of the future bath, the possibilities of using various types of fuel, consulting specialists can be searched for the choice of the furnace. Reliable and durable furnace does not have to be the best or expensive. The main rule is the compliance of the model of operating conditions.

From manufacturers, it is possible to advise the products of domestic companies "Teplodar", "Ermak", "Thermophore", "Varvara", "Feringer", as well as foreign stoves Harvia and Kastor.

Here we have only two options: either this furnace, including the fuel core, will be made of brickor from metal. As the last, either different steel alloyseither cast iron.

Brick

Brick - traditional furnaces, if you do not pay attention to the fact that the tradition is not on the times of Peter I. Lovers of the Russian bath are very respectfulThey are considered the most correct. Weight big, need separate. Come go expensive - And according to the material, and for the work of the Master, the Pechnik (the cheap calling does not make sense, it is better to put it yourself). Therefore, customers preferring should choose another option. During operation required permanent care and prevention - drying, careful ignition, liquidation of cracks in solution, etc. but Do not like a brick stove mainly for preparing the procedure takes 4-5 hours.

Metal steel

The most commonbecause the manufacturer is easier and more profitable to do from steel, and preferably - from the structural, that is, not doped, rust, because the cost is reduced. However, there are those who laid into products and stainless steel ( and not only for the hull, but also for firebox), and the thickness gives more than 2 mm. But the price, respectively, grows. Read our materials - we tried to find out where which metal is used. At the same time, all the stoves were equal to us - neither pegs or negative to whose products.

Metal cast iron

Unhappy if they do not beat them) no, in fact, very durable and at the same time fragile stoves - Not one dozen years can be operated, but at the same time they are afraid of sudden temperature differences and mechanical shocks.

Unhappy if they do not beat them) no, in fact, very durable and at the same time fragile stoves - Not one dozen years can be operated, but at the same time they are afraid of sudden temperature differences and mechanical shocks.

In addition to the strength of the cast iron, it is worth mentioning its heat capacity - it is higher than steel, but here not the last role plays and big than steel wall thickness - up to 4 cm in some parts of the design, and on average 1 cm (against 0.2 with steel!).

On a note! Cast iron take a bath either those who love to steam "in Russian" or those who want to invest once and for a long time. Well, or those who combine both.

Types of bunny fuel stoves that are used in them

This is also a fairly simple classification, because as fuel for bath furnaces can be used:

- firewood;

- electricity.

However, there are options that allow us to use alternately two types of fuel. As an example, we call gas-wood furnaces, which can be read in the article on gas (see the link below). In addition, there are furnaces capable of working on both gas and diesel fuel.

Woods

There are no complaints about the lack of firewood in Russia, so wood-burning furnaces are not losing popularity. Of course, to this type of fuel a lot of complaints, but cheapness Much reaches.

There are no complaints about the lack of firewood in Russia, so wood-burning furnaces are not losing popularity. Of course, to this type of fuel a lot of complaints, but cheapness Much reaches.

Varieties of wood stoves a lot, especially homemade. But among the shops are the most numerous category of goods. We not only prepared descriptions of various nuances related to, but also drawn up the ratings and reviews of the most popular models, which should significantly facilitate the flour of choice at the existing diversity.

Gas

Everything is well in the gas stove - the fuel is not the most expensive, but much more comfortable, because there is no common freak with firewood, the temperature controls the thermostat, automatics follows possible problems ... yes only it is dangerous this stove. The usual can cause a fire, but gas - still undermines everything. Therefore, it still needs to get permission from the authorities. In addition, all the equipment must be certified And no homemade is allowed. But you can not buy the whole stove of the whole, but only the gas burner to convert the wood-burning furnace to the gas is a completely permissible move, by the way.

Read more about gas bathrooms -.

Electric

The overwhelming majority of electrocamenakes are used in the saunas. Nothing strange: for saunas they were invented.

The overwhelming majority of electrocamenakes are used in the saunas. Nothing strange: for saunas they were invented.

Furnaces for the Russian bath and for the sauna: what where?

Since we have somehow concerned more than once or other issues of furnaces of furnaces for a national bath, then let's tell us briefly about the criteria for this suitability. And let's start with our, Russian bath.

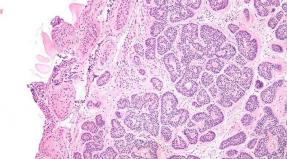

First, inside your oven must necessarily closed Kamenkawhich is inside the firebox. This is either a grill on which stones are laid or a closed container of solid metal. In both cases, the door leads the door that you open when you want to pose water. If the stones lie in open videoThey will never warm up to the desired temperature, unless the steam gun put.

Secondly, this closed heater must heat up long enough for the stones to warm up to 400 and higher degrees. And this means that for these hours, the steam room should not turn into a branch of the fictional "Fiery Hell". This is possible only if the furnace is made of brick or has a brick, or a stone casing that closes it entirely (except for the floor). Well, and if there is an opportunity to completely overlap convection.

Russian bathing stove with closed stone

At all, an acceptable stove for the Russian bath can work not only on firewood, but also on gas, and on electricity. The main thing - so that she had a closed heater, casing and controlled convection (Mesh hubs are not suitable).

Useful video

The following movie (from a company specialist) may, somewhat and subjective, but very informative and completed the above, we recommend. The author leads not only the pros and cons of different types of furnaces, but also compares each with the products of the enterprise, in particular with the aggregates and.

We invite everyone to participate in folk ratings - just put a tick on a stove or furnaces that prefer. So you help other readers find your own option. And, of course, write comments - the answers to the most pressing issues will be new articles on our website.

Where can one buy

Companies specializing in the production and sale of stoves offer various types of aggregates. Some suppliers are presented on our website, in the "" section.

The selection of a bath furnace is the most responsible process. The main criterion is power. The calculation must be correct, it is important not to be mistaken. If power is insufficient, the bath will warmly and quickly cool. If you put too powerful boiler, it will not be possible to go there. There are other selection criteria. How to pick a stove for the bath right?

Power stove

Power is selected on the basis of the calculation, the content is given below. To carry out the calculation, measure the main dimensions: length, width and height. To obtain a clean volume of the bath, it would be enough to simply multiply these numbers.

However, it is so easy to allow an error. How to make a difficult choice - pick up a stove for a bath? When counting the volume you need to make the following adjustments:

- Usually in the steam room makes the most efficient thermal insulation. The walls first inspire, only then they are trimmed with finishing material. It is customary to use thermal insulation with a foil layer, which reflects heat back to the bath. The problem is that when the finished log house is ordered, heat insulation is often neglected. It is permissible, but it is worth considering that the tree is a very heat engine material, its thickness - from 20 cm. Part of the heat will go to heating the logs themselves.

- If the furnace part of the stove is submitted to the pre-banker, it is "Break" in the heat insulation. It is necessary to take into account this in the calculations.

- Doors and windows must be carefully insulated and tightly fitted. Otherwise, this is also a fate.

- If there is a ceramic tile, brick, natural stone in the bath finishes, part of the heat will go to their heating.

Just considering all the above, you can correctly calculate the volume that will have to heat the device and choose which stove in the bath is better. To take into account all these parameters apply the correction factor - 1.2 m 3 per 1 m 2 poorly insulated or absorbing heat surface.

Example: The steamer has a size of 2x3x2.2 m. There is no insulated window 0.8x1.2 m and the door is 1.8x1 m. Calculate the volume: 2x3x2,2 + (0.8x1.2 + 1.8x1) x1,2 \u003d 13.2 + (0.96 + 1.8) x1.2 \u003d 16.5 m 3. We take power: 16.5 m 3 x 1 kW ≈ 17 kW. note that 13.2 kW ("Clean" volume) We would not enough.

Additional selection criteria

Power is the main criterion, but not the only one. What are the furnaces for a bath? That the result is fully consistent with our expectations, you need to take into account the following:

- material material;

- firework design options;

- pair type;

- various designs;

- kind of heater;

- work time from one fuel refueling;

- features of bath warming;

- what fuel is used.

Just considering all this, you can determine which stove to the bath is better.

Material of manufacture

Bath furnace can be made of:

- cast iron;

- become;

- brick.

What stove in the bath is better if you take the material of manufacturing? Compare them between themselves is not entirely correct. Each material is better solving this or that task and, according to experts, creates a special atmosphere.

With a modern assortment of furnace equipment, experts give the palm of the championship with special heat-resistant doped steel with the addition of chromium. It is steel, today, is the most reliable and durable. The atmosphere in the bath does not suffer. Such furnaces do not burn oxygen, since when burning in them there is no oxidation process.

When choosing reliable bath stoves, the site website recommends paying attention to Finnish companies. They deservedly occupy a leading position in this market. Their products have one drawback - a high price. Although, the same "Harvia" produces rather budget models.

Harvia Bath Stove

The production of cast iron stoves today is not particularly popular. The lack of a cast-iron furnace is a lot of weight and shorter, compared with the previous version, service life. Heating is slower. It is worth considering, deciding which stove to choose for a bath.

Cast iron stoves today are not partable popular

Selecting a brick furnace - tribute tradition. Install such very laborious. There were not many good masters before. Now - you will not find at all. You can try to build a stove yourself, but is it necessary? This work is not simple - you need to properly build a foundation and chimney, and the result will clearly give up to modern industrial samples. Brick requires more energy to warm up, so fuel consumption will increase.

At the same time, although such a stove and will rush longer, it will be much longer and give warm. It all depends on your financial capabilities and personal preferences - sometimes, such a stove is a good choice.

The brick option is long, expensive, difficult.

Features of the layer location

The furnace can be located in a closed steam room, but it is much more convenient when it is remote. This complicates the selection of a cast-iron, steel or brick furnace. You can add fuel at any time without interfering with those who are in the steam room. It slightly reduces the thermal insulation of the bath, but not critical. The new thermal insulation of all adjoins and seams will solve this problem. But the door to the steam room will open less often.

The new coat of firebox, made of heat-resistant glass, will allow you to follow fuel consumption. The remote firebox itself must be made of thick heat-resistant steel with the addition of chromium. Such a design is an indicator of quality, will not progrit for years and will withstand the highest temperature.

Para

First we will deal some couples. Distinguish:

- Dry steam is most useful for the body. Stones are heated to +500 0 S. It is worth splashing on them warm water - it instantly turns into steam. Such a couple evenly warms the entire bath and does not increase moisture.

- Wet steam - arises as a result of boiling water directly in the bath. Hot water is also heated by a heater that is equipped with a water tank. This method does not require the supply of hot water. For washing use water directly from the boiler. She is a heat exchanger.

How to quickly choose a stove for a bath in that case? Fans of wet steam can organize a similar process in the sauna. For this there is no need to put the boiler with water. It is enough to buy a special device, which will produce steam. The principle is the same, only works steam generator from electrical energy.

Requirements for construction

When choosing a furnace in a bath, you need to take into account the requirements for the stove design. She must:

- provide gradual and uniform warming of the bath;

- heated the room to +80 0 C (under the ceiling) for 3 hours;

- ensure proper fire safety;

- eliminate the likelihood of smoke and soot in the bath;

- preheat stones up to +500 0 s;

- ensure convenience of operation;

- have aesthetic appearance.

Type Kamenka

What should be a stove-heater in the bath? There are two types of heaters:

- open;

- closed.

What are these types of bass furnaces from themselves?

Open - heating the air of the room directly with heat, which is given to stones. The most optimal option for frequently visited. This option is often used for individual use. Quickly heats the bath, but also quickly and cool. It is needed in the country area.

Closed - deciding which furnace to install in the bath, pay attention to the stove having a damper that closes the top layer of stones. The room will warm up more evenly, due to convection. Fuel - spend more economically. There is also a reverse side of the medal - to start trample the bath will have for 3-4 hours.

What kind of furnace to put in the bath, considering the type of heaters? Here everyone chooses himself. Their pros and cons. We looked higher. But by experience, let's say, it is better to use stoves with a closed heater.

Duration of work on one fuel bookmark

Another important characteristic - how much will work on one fuel laying. The longer, the better. For example, the efficiency of a conventional brick furnace is about 85%, and the ovens implementing the long-term combustion technology due to the pyrolysis process - 91-95%. Accordingly, the second option will work more efficiently. The efficiency of the efficiency is needed to use the fuel as rational as possible, the amount of which can be different.

The furnace can work not only on solid fuel (firewood), but also on gas, liquid fuel, from electricity. In each case, you need to calculate the optimal option. The source data is individual. Accordingly, the result will turn out for each one. Choosing a stove for the bath, consider the characteristics that the manufacturer pointed out in the passport. If you decide to make a furnace yourself - calculate in advance and appreciate the possible efficiency.

Standard brick oven on firewood, with remote furnace, will burn for about 4 hours. Long burning technology will increase this time up to 30 hours.

Features of the premises of the room

There are two options: hot and cold. Hot - the walls of the furnace, heating more than 100 0 s, warms the entire room. Cold - the walls of the furnace are isolated and not heated above +40 0 C. Warming up the room comes at the expense of special channels in which air circulates. Each method has its pros and cons.

Hot - quickly warms the room, but there is a possibility to get a burn. You must arrange a protective screen of bricks.

Cold - more secure, the bath warms up more evenly and cools longer, but the process takes longer.

Type of fuel used

The baker for the bath can work almost on any kind of fuel:

- natural gas;

- solid fuel (firewood);

- wood processing products (pellets from pressed sawdust);

- liquid fuel;

- electricity.

Classic option - bath on firewood. Experts claim that no other type of fuel is capable of creating such an atmosphere. In modern conditions, this statement is quite controversial. Modern manufacturers with high rating offer analogues working both on gas and electricity. According to technical indications, they are not inferior to furnaces on firewood. Gas is the cheapest type of fuel, and the cost of firewood is steadily growing. The main thing is not to be mistaken with the choice.

Choosing a wood-burning furnace

When choosing a good wood stove, you should pay special attention to the following factors:

- design features;

- principle of operation;

- manufacturer (more precisely, its rating).

Design features

The combustion temperature is high so that the furnace does not boost, it must be made of high-quality metal. Turn the furnace will have at least 3-4 hours. It is worth remembering that the following elements include in the design of such a furnace:

- Solnik - used to remove combustion products (ash).

- The furnace is different designs. Most preferably put the elongated, which will allow you to install the furnace in the wall so that the furnace is in the adjacent room. Metal thickness should also be sufficient.

- Gas burning gas - used in pyrolysis of long burning boilers. Allows the oven to burn to 30 hours on one fuel tab.

- Kamenka - directly heats the air in the bath.

- Chimney - serves to remove gaseous gorgeous products.

The need for an additional foundation device and the complex design of the chimney led to a decrease in the popularity of traditional wood-burning stoves from the brick.

Principle of operation

On the principle of operation of the furnace on firewood divide on

- long burning;

- periodic burning.

The advantages of a long-burning oven are obvious: this is saving fuel as a result of the pyrolysis process. Constructive feature - the presence of a chamber of the gases obtained as a result of pyrolysis. The disadvantage is the formation of soot. It is not recommended to pour water on stones, which, by the way, is needed much less. Otherwise, it is possible to release soot into the bath. The heating temperature of the stones is not higher than +350 0 C. But, fuel economy can be up to 500%.

In the furnace of periodic action - the stones are heated by open fire to a temperature of about +500 0 S. Sozha simply burns. You can safely pour water on the stones.

Manufacturer

Furnaces and Swedes are confidently headed by Finns and Swedes confidently. Such manufacturers like "Kastor", "Harvia" and "Helo" (Finland) and "Tylo" (Sweden) are especially popular. Russians are not yet somehow confidently compete with these manufacturers.

Choosing an electric furnace

The main feature of the electric furnace is a constant need for electricity. If a standard 220V network can be used to 7 kW, then over 7kW will require additional lines of the line in 380V. Not always and not everywhere it can be convenient, and, and, in general, maybe. The new furnace for a bath can do too expensive.

Advantages of electrocamers

The benefits are obvious:

- do not require the construction of complex structures (chimney, foundation);

- can be installed in almost any bath, where there is electricity;

- safety;

- a closed system with a heat exchanger is possible;

- durable, stainless steel;

- ease of operation.

Basic selection criteria

What electric oven is needed in the bath? Criteria for the choice of specialists Standard:

- the presence or possibility of supplying the required voltage;

- power heat exchanger;

- the price of electricity in a particular region.

Selection of a gas stove

Gas furnace completely eliminates any independence. This is a source of increased danger, so installing and connecting work can produce specialists with appropriate tolerances and licenses.

Benefits and design features

Natural gas is the cheapest fuel. This is its main advantage. The efficiency is the highest, when using low-temperature equipment, up to 109%. This is exactly what explains the high popularity of this equipment.

However, natural gas is far from everywhere. This is the main drawback.

Choose a furnace for a bath on a gas - check the following:

- The burner of the modulation type. Such a burner automatically selects the optimal mode of operation, depending on the specific conditions. This allows you to maximally reduce the negative effect of the fuel unlikely.

- The coolant (hot water) must be warm up to +70 0 The temperature of the gas should not exceed +110 0 C.

- Use coaxial chimney.

- Have a gas recirculation system.

Under such conditions, the efficiency will be maximal.

About gas-wood ovens

There are modifications that can work both on gas and wood furnaces. This allows you to simultaneously solve several problems at once:

- improves the convenience of control;

- in the absence of gas, you can use firewood.

Installation requirements

Only specialists with all necessary licenses and permissions admit to the installation of gas furnaces. All fire safety standards must be met.

Output

What bass oven is better to choose for a Russian bath? It is impossible to give an unambiguous answer, but it is worth stopping the choice between wood and electric stoves, because Gas is not carried away everywhere. Further, the main criterion for choice is the power of the furnace. We led to the calculation formula above. The remaining parameters depend on your desire and wallet.

True defining the initial data, the selection of a furnace for a bath in parameters is not difficult. All characteristics are indicated in the product passport. Among the manufacturers, the first place confidently hold Finns, offering, including quite budget systems. The presence of a Russian-speaking site and the design of the body also affect the choice, which is not so small, as I would like.

← Previous article Next article →The oven is the heart of any bath. Wood, electrical or gas, homemade or factory production, budgetary or expensive - in front of a person who decided to acquire their own bath, an almost unlimited range of stoves opens. We decided to facilitate the task of choice and systematized the basic requirements for such installations, having taken into account all the significant moments.

The furnace can be sustained in any overall limits, to work on different fuel and have the most diverse design, but 2 key requirements are primarily presented to it:

- optimal Power Poles for Specifically Taken;

- installation in compliance with approved rules and regulations.

Power is the first thing to pay attention to when choosing a furnace. To bring some specific universal figures meaningless - this is in principle impossible. The main thing is that this indicator is optimal for a particular case.

Already at this stage, many developers admit a big mistake, acquiring a furnace unit with a large power supply, calculating that this will reduce the time spent for heating the steam. Yes, the room will heat up faster, but then the oven will go to the minimum mode of operation. The result is one - the air will be hot, stones are cold. Pouring water to insufficiently warm stones are meaningless - steam in such conditions either not formed at all, or will go clubs like from the kettle. And in the bath, as you know, steam should be transparent and easy, otherwise it will be extremely unpleasant in the steam room or simply impossible.

Kamenka in Ban - Photo

An error is the other extremes - the installation of a low-power unit in order to banal reduction of the total cost of arrangement of the steam. Even if the oven with low power and warms the room to the required level, it will have to "enhance" to maximize. How do you think with a system that is constantly working on wear? That's right, it breaks very quickly.

Important note! Do not pay attention to such an indicator as the power of the heat source can be exclusively in the event of the construction of Hamam (), in which there is no oven in its classical understanding. But we are talking about the bath, so we consider the aggregates designed for operation in its terms.

- power is usually measured in kW;

- the volume of the steam, which can qualitatively serve the stakeholder furnace.

To get rid of yourself from complex long-term calculations, let's go easier: I will define the volume of the steam room and, repulscing from it, set the required power.

First step. Calculate the volume of the pair room. To do this, we need to measure its length, width, as well as height. After moving the numbers obtained, finding the volume indicator thus. If the project documentation has been preserved, we turn to it and save yourself from this stage of the calculation. Suppose the length of our wage is 2 m, the width is 1.5 m, and the height is 2.2 m. The volume of this room will be 6.6 m3.

The second step. Carefully inspect the walls and the ceiling. Here we need to determine if there are uninsulated plots on them, for example, masonry, tile facing, double-glazed windows, etc. We consider the area of \u200b\u200beach such plot (multiply length and width). We summarize the values. For example, we have a window with dimensions of 60x60 cm and tires 100x100 cm. Calculation is:

(0.6x0.6) + (1x1) \u003d 1.36 m2.

The resulting number is multiplied by a coefficient of 1.2 - this gives us a new value, equal to 1.632. We add to the volume of the steam and we get 8.232.

Third step. If the door to the steam room is made of glass, we increase the final number from the previous step by 1.5. Result - 9,732.

In the presence of a glass door, we increase the calculated coefficient

Thus, the stove must be designed for heating 9.732 m3. There is a very important note: in the concomitant instructions for furnaces, work volumes are indicated in the intervals, for example, 4-9 m3. In our example, it is reasonable to get a stove with some reserve, for example, the unit for 7-12 m3 is well suited, while the stove resource for 5-10 m3 will not be enough.

When determining the desired optimal power in kW, it is customary to adhere to regularity, in accordance with which 1 m3 of space takes 1 kW of power.

Important! So that the Kamenka successfully coped with the maintenance of the room stated by the volume manufacturer, load it exactly with such a number of stones, which is recommended in the concomitant instruction.

Additional selection criteria

Determining the required parameters of power and working volume, we can give themselves to "get roaring" with respect to related criteria for choice.

Material of manufacture

Most often, the furnaces are made from such materials: cast iron, steel, brick. The service life of the structure directly depends on their quality.

The most durable is currently being considered modern stoves made of chromium steel. Such installations produce "clean air", which eliminates the risk of burning oxygen in the room. The best steel stoves produce Finnish companies Helo and Harvia.

Meet a bath stove with cast-iron furnace today in the wonder, although this material, in principle, is very good. Among the factory stoves with cast iron furnaces, it is possible to pay attention to the model "Sudarushka M" of the production of a domestic company Inzhkomcentre.

Brick stoves - tribute to the history and reverence of ancestors. If you find a good cook - will be satisfied with the long-decades ahead. But also their shortcomings of such aggregates have:

- comparative complexity of extracts with multiple nuances;

- relatively long heating;

- the need for an individual powerful foundation device, which leads to a significant increase in total costs.

Features of the layer location

Furnaces with firefalls of two varieties are available on sale:

- elongated for mounting in the wall;

- ordinary.

The first allow you to organize the furnace of the stove from the adjacent room with a room parillery, so that fire safety indicators and the microclimate are increasing, but such models are more expensive.

Para

In the traditional Russian bath, steam should be dry and easy. However, it is precisely such a steam that is capable of producing such a modern oven. For maximum comfort, it is reasonable to buy a separate electric steam generator - so you can solve all the problems associated with this moment.

Bath steamer - Mounting scheme

Video - steam generators for bath and sauna

Requirements for construction

A good furnace should be able to:

- protect air to 40-50 degrees at the bottom of the room with a gradual increase of up to 80 degrees under the ceiling;

- it is relatively quickly heated by stones and maintain their temperature at the required level;

- eliminate the likelihood of penetration of smoke and carbon monoxide into the room of the steam room.

Additional requirements remain at the discretion of the owner. For example, someone may be important that the stove knew not only to heat the room, but also prepare hot water.

Video - Hot water in the bath, water heater + strapping

Type Kamenka

For the most part, private stoves are equipped with open or closed chambers.

Duration of work on one fuel bookmark

Ideally, if the furnace will give heat for the maximum possible time without the need to add a new portion of fuel. This criterion is determined by the user individually.

Bath furnace furnace - Photo

Here the choice is small.

The furnace can be:

- hot. Heat is given through the outer walls of the oven, warming up to 100 degrees and more. Highly a good option For a private wage. But there are also its drawbacks: it is difficult to adjust the heating temperature and can be burned. To eliminate the unpleasant consequences, the heating parts of the stove must be carefully insulated, for example, using a brick screen;

- cold. The walls of such an aggregate will not be heated stronger than 40-45 degrees. Improved directly through circulation channels. Such furnaces are safer and easy to operate.

Type of fuel used

| Type of fuel used | Description |

|---|---|

| The most traditional and popular option. It guarantees uniform and fast heating of the room with the creation of the maximum favorable microclimate. Wood furnaces can be treated "black" and "on white". In the first case, the chimney is usually not done - Gar is removed through the outlet in the wall or overlap, or simply through the open door. The furnace "on black" today is almost not found - not aesthetically and difficult. The oven "On White" is a traditional version of the modern wood stove. It is necessarily equipped with chimney. The shortcomings can be attributed to the need to follow the process of burning and periodically exaggerate the fuel. | |

| Good, safe and modern option. Electrocamenakes provide quick warming of the steam, while the user gets the possibility of maximally precise control of the temperature and humidity regime in the room. For the furnace correctly and reliably worked, a stable supply of electricity should be present at its place. The main disadvantage is a fairly significant cost of electricity, the value of which in many regions is high. | |

| If preference is given to this type of fuel, there can be no speech about any self-identity - only high-class certified factory manufacturing units installed by qualified masters. A gas furnace is very convenient in operation, it can be automated. Along with this, it is recommended to consider this option only to residents of those regions in which low gas tariffs have been established, and there is no possibility of regular replenishment of firewood. Under other circumstances, heating costs will be more substantial compared to the expenditure for the operation of a traditional solid fuel furnace. |

In general, the knowledge gained is already enough to choose a good bath for a bath. The only thing we would like to dwell in more detail on the question of choosing a furnace unit in accordance with the type of fuel used for its operation.

Features of the selection of a wood furnace

Traditional wood stoves have a fairly simple design, a list of the main elements of which includes: ash tank, firebox, gas ducts, heater and chimney. Additionally, includes related elements that increase the indicators of functionality, safety and ease of operation of the furnace.

For example, the furnace can be recycled with a tank for water heating. It is very convenient if it is placed on the chimney - the heat of the outgoing gases will not just fly through the pipe, but to warm the water in the tank. The space of the parley is heated by stones and walls of the furnace housing.

The order of wood bookmarks may vary depending on the characteristics of a specific model. There are few options.

- Internal laying. The fuel is loaded into the stove directly in the room of the steam.

- Outdoor tab. Fuel loading is carried out from adjacent rooms.

Existing varieties of wood stoves can be classified according to several main indicators. About them further.

Design features

Wood furnaces can differ significantly in terms of the features of their design. Classification is shown in the table.

Table. Structural variations of wood bath stoves

| Varieties | Description |

|---|---|

| Stones are placed exclusively on top. The furnace is equipped with either glass or an ordinary deaf metal door. | |

| The feature of the furnaces of this category is that the casing in them has a form of a grid collected from metal rods. | |

| Such furnaces are equipped with a special capacity. In it, the user can pour water in order to further use to create a pair. | |

| In a separate view, it does not need - the design is equipped with a container for the preparation of hot water. |

Principle of operation

In accordance with the peculiarities of functioning, wood-burning furnaces can be classified into groups below:

- furnaces of long heating. We work using a relatively small number of stones separated from the furnace using a metal sheet. Stones in most cases do not heat the stronger than 350 degrees. Watering their water professionals do not advise - high risk of emissions of soot particles into the ambient air;

- furnaces of periodic heating. These units are loaded with plenty of stones. The partition mentioned in the previous paragraph is missing - the stones are heated by open flame. You can safely print water - soot will not be thrown away. The optimal option for a private wage.

Manufacturer

In the modern market, a truly impressive range of bath stoves is presented - choose from what. Yes, and instructions on self-laying / welding of the stoves allow you to make an aggregate on our own, saving money. What to do - everyone has the right to solve independently, focusing on the affordable budget and personal preferences.

We, based on the reviews of real users, we can suggest pay attention to the products of two industry leaders.

First, it is Harvia ovens.

A huge model range, many stoves with different functionality and design - will be able to select an option without any problems, fully appropriate to your requests and expectations.

Harvia ovens - High quality and stylish design

The manufacturer offers both traditional floor units and designer wall and angular variations. Harvia products are characterized by very high quality, trouble-free operation and long service life. For the manufacture of furnaces such furnaces, modern high-strength steel is used, the thickness of the upper part of which is 1 cm and more, which is a guarantee of the highest strength of the heater and the long service life.

Patented fire-resistant paint, maintaining its original qualitative characteristics at a high level for a long time, applies to the outer coating of the corporate furnace case. In the range of the same manufacturer, many additional elements are presented, ideally combined with corporate engines and contributing to a significant increase in their functionality.

Prices for wood ovens Harvia

harvia wood stoves

Secondly, these are solid fuel furnaces Helo.

The range of companies present both budget versions and luxury models for true connoisseurs. For the manufacture of external walls of branded furnaces, the best stainless steel is traditionally used.

The highlight of many models is a door with an insert from heat-resistant glass - you can follow the process of burning, enjoying the view of the flame, which creates an excellent relaxing atmosphere. For the firebox most furnaces of this brand, not only firewood are suitable, but also peat briquettes. You can choose a stove with a tank for water, installed either above the stove or by remote technology.

In more detail, as well as solid fuel bath furnaces have already been considered in the relevant publications of our site.

Features of the choice of electric oven

Electrocamenakers - Photo

Advantages of electrocamers

Electrical bath ovens have many advantages.

- First, they are compact - the average electrocamenkin in any circumstances takes less useful area than gas and, moreover, a solid fuel unit.

- Secondly, they are very convenient to use. As noted, the user is not only available to the possibility of controlling the temperature and humidity indicators, and the organization of full automation.

- Thirdly, they do not imply a chimney arrangement. In view of this, directly installation of the furnace will require much more modest financial investments compared to other possible varieties of aggregates.

- Fourthly, in the steam room with an electric stove will always be pure: about ash, smoke and dust can be forgotten.

- Fifth, modern electricians from proven manufacturers serve longer if compared with simple solid fuel devices of a similar price category.

- Sixth, electric stove is extremely easy to operate. The user needs only to turn on the device and wait a bit.

Yes, and there are no significant restrictions on the choice of the installation site of the furnace - it can be placed at least about the wall, even in the center of the room.

Electrocamenki benefit and in relation to security issues: thoughtful and competently organized cyclicity of work, the presence of sensitive automation and protective shutdowns allow you to minimize the likelihood of various kinds of troubles for devices operating on the principle of fuel combustion.

For the maximum convenience of operation, many models of electric bath furnaces are equipped with built-in either, which is even better, remote controls.

For heating the steam room, the electrodelock leaves relatively little time, and the heat-dimensional heat is characterized by softness and uniformity.

Prices for different models of electrocamers

electrocamenka

Basic selection criteria

The main parameters that need to be taken into account when choosing an electrical bath furnace are given below.

- The volume of the facilitated room and the required power of the system. Recommendations for the calculation of this moment were considered earlier.

- Control and regulation elements. As noted, the electric furnace console can be built-in either remote. Here everyone should solve himself that it is more convenient.

- Characteristics of the heater. One of the most important moments. Modern bathing electrodes are equipped with shadan, ribbon and combined heating devices.

The TENNA (tubular) can hear up to very high temperatures, but it serves relatively little. If you decide to buy a stove with a shadan heater, check it to be made of stainless alloy.

Ribbon devices are characterized by more high rates The speed of heating, environmental friendliness and efficiency, while they are not so much burned to the air as the penny "counterparts", and they serve noticeably longer.

Combined options combine the heaters of the two mentioned types. For the price they are the most expensive, but ensure the rapid speed of the speed and temperature of the warming of the served room.

- Design. Electric furnaces can have a wide variety of dimensions, shapes and features of design. With regard to these moments, the decision remains for the buyer.

- External execution material. The stove can be both closed in a beautiful metal case, and is decorated with a natural stone, for example, talco chlorite or talcomagnesite.

The application of the facing does not simply improve the external quality of the stove, but also carry out important practical functions, namely: increases the protection of the user from the effects of IF radiation, contributes to the accumulation of heat, eliminates the convection temperature differences, ensures the creation of an ideal uniform thermal background, it has a positive effect on the human body.

Important! When planning to purchase an electric bath oven, require the seller to show the certificate of compliance with the requirements for such systems and fire safety parameters. In the absence of such it is strongly recommended to refrain from buying a furnace.

In more detail, the nuances of the electrocean selection for the bath and the recommendations for its installation were in the appropriate publication of our site.

Features of the choice of a gas furnace

Gas bath furnaces are becoming increasingly popular - the desire for maximum convenience prevails over love for the flavor and the smell of burning firewood.

Aggregates working on gas burning have several advantages, including:

- economy;

- high speed of room warming;

- the lack of the need for tracking the remaining amount of fuel and its addition.

Along with this, before giving preference precisely the gas unit, you need to get acquainted with a number of rules and features of its installation and subsequent operation.

Benefits and design features

The traditional bath stove, which works on firewood, is excellent in every sense - it is also traditional. But what to do if the mining of firewood is of great difficulty? Use gas!

In the photo - Gas furnace with a remote temperature regulator

Such a solution has many advantages.

- Installation compactness. The gas stove, unlike its wood-haired "fellow", does not have a large firebox and massive ash bar - here they are very compact, which makes it possible to install this kind of equipment even in the most close steamers.

- Optimality temperature mode. Gas furnaces are extremely simple in management - exhibit the desired mode and enjoy the rest, forgetting about the campaigns behind new portions of firewood and cleaning unburned coal.

- Features of the internal device. The classic structure of the gas bath stove is as follows: there is a housing, it has a gas burner, a fuel source is connected to the burner. Additionally, a water tank may be present. From above placed pallet for styling stones. In the same area there is a device responsible for the discharge of combustion products.

Separately, it is worth staying on the stones. In the complex with a gas stove, it is best to use round-shaped cobblestones extracted from the marine or river bottom. Due to the peculiarities of its origin, they are best suitable for use in extreme conditions of the steam.

In addition to the above-mentioned elements, the design of each gas bunk furnace necessarily includes a thermostat to control the temperature and the fuse, the forces of which turn off the fuel supply in the case of a sudden flame damping.

In the people, gas stoves are jokingly and, at the same time, they are called "bombs". The problem is that many people, again, in their desire to save money they come too far and either buy unattended equipment, or they collect it with their own forces without having appropriate skills and qualifications. As a result - burns or, which is much worse, fires and explosions.

Video - Gas burner for brick bathroom furnace

In practice, many buyers managed to personally familiarize themselves with all the advantages of gas bath stoves. You can also join them if you follow the relevant rules of choice, subsequent installation and operation of such equipment.

First, pay attention to the gas burner. Each burner is designed for a specific gas flow rate. In accordance with this indicator, such important characteristics are determined as the power of the stove and its efficiency. In relation to the choice of burner for the premises of a particular area, the seller will consult you - these moments may vary depending on the design features of the equipment, the characteristics of the steam and other concomitant moments.

Secondly, the furnace should have appropriate certificates of quality and safety. In the absence of those, go away from the dubious seller, even if it suggests you a significant discount and will try to try to convince the safety of equipment.

Of course, the furnace as a whole and any of its components in particular should not have any external defects in the form of damage, cracks, leakage compounds, etc. In addition, even the most impeccable gas stove must undergo a regular prophylactic inspection. It is strictly forbidden to neglected - the security of the baths and life of users on the horse.

A few words about gas-wood furnaces

In the range of many producers, gas and wood stoves are presented - this is a modern universal solution that can work with the use of different types of fuel: firewood, as well as liquid hydrocarbon gas and its natural variety.

This became possible due to the simultaneous presence of devices for burning solid fuel and special gas-melting equipment. Additionally, a fuel collector is included in the design - without it, the use of firewood as a fuel would be impossible.

The greater advantage of gas-wood furnaces is their relatively low cost with wide functional operational capabilities.

Requirements for installation of gas bath stoves

Important! Installation of such equipment should perform an exceptionally qualified master. By installing your own forces, you are very risking. Along with this, several important recommendations should be remembered - the knowledge of those will allow you to trace the correctness of the work of the installer.

- Between the oven and the nearest walls should be withstanding at least a 50-centimeter distance. Blood surfaces are necessarily closed with non-flammable materials.

The scheme of the furnace is one of the possible options.

- The furnace is installed on a refractory base of such sizes so that it is at least 100 mm on each side of the furnace.

- The requirements for the sizes of the opening must be complied with gas burner - Specify in the instructions for a specific aggregate.

- To connect the gas bath stove with chimney, use stainless pipes. Compound design. The pipe is moving into a pipe minimally by 50% of its diameter.

- Doors leading from the wage must open out.

- The height of the chimney pipe is calculated so that it is at least 500 cm towering over the burner. In relation to the roof, the traditional half-meter elevation (minimum) is maintained.

- The location of the compound of the gas bath oven with chimney is subject to perfect sealing.

In all details for the baths were previously studied in the relevant publication of our site.

Now you own all the necessary information regarding existing varieties Bath furnaces and features of their functioning. Successful choice!

Video - How to choose a stove for a bath

With all the variety of metal bath furnaces manufactured by the industry, there is a clear separation of products to classes and groups. The applicability of models is due to the operating conditions and obtaining the desired result on temperature and humidity modes. To get a more visual picture of a possible choice, we reduced the main characteristics of the existing structures of iron furnaces for baths into one table. Having received an initial idea of \u200b\u200bthe peculiarities of certain groups, you can make a conscious selection of the furnace without spending additional funds and time to search.

The purpose of the article: Provide reliable information to potential buyers of bath furnaces and help in choosing the optimal model.

| The heat drying of the furnace should be sufficient to warm up the steam and adjacent rooms for a short period of time. The optimal time is the heating of the steamer in the summer, 30-40 minutes, heating the steam and adjacent rooms in winter at a temperature of -10 ° C for 2 hours. | |

| Sufficient capacity of the heat battery (stones) | The two most important parameters for bathing stoves are the mass of stones and their temperature in normal operation. To create a Russian bath mode in a steam room, you need to evaporate 100 grams of water to the cubic meter of the room. At the same time, steam should be "transparent" with a good degree of warm-up and the temperature of the stones should not fall more than 100 degrees. Otherwise you will get "heavy" and raw pairs. Calculations show that at least 5 kg of stones (minimum), and the optimum amount is in the range of 6-8 kg per cubic meter of the steam room. The temperature of the stones in normal operation of the bath furnace should be 200-250 degrees, which can be achieved if the design of the heater is closed or non-ventilated. |

| The presence of a steam generator to create the necessary modes | This item is directly related to the design of the heater and the previous parameter in the table. Water delivered by the steam cannon in the central part of the heater evaporates with the creation of an optimal steam, slightly reduces the temperature of the stones and ensures uniform steam supply throughout the room. |

| Firing material | For good furnaces, stainless steel with a chromium content of at least 12-13% is used, ideally at least 17%. |

| Basic Requirements for Banners | Description of the requirements for baths |

|---|---|

| Sufficient thermal power | It should be borne in mind that heating air in steam room and adjacent premises takes the minimum time compared to the heating of walls, ceilings and floors in the bath. Consultants in stores, as a rule, are proposed to use cubic meters in the room in the steam room, which does not give a complete picture of the sufficient furnace power. for example, Warming up the steam of 8 cubes in winter will require 4 kW for 1 hour. Since both the oven itself, the heating, water in the tank and the screen occurs at the same time, then increase the thermal power to the coefficient 3. We obtain a value of 12 kW. If the steam room is not uphawing and warming the log logs, then use another coefficient - 1.5. We already receive 18 kW. And when heating adjacent premises, we increase the resulting power at 2. A sufficient power of the furnace in our case will correspond to a value of 36 kW. If you do not rush anywhere and agree to wait not one hour, and two hours before the bath output to the mode, then it is enough to multiply the power to 1.5. |

| Firing material | Most inexpensive bath furnaces are made of structural steel, the strength of which falls quickly when heated. The combustion temperature of firewood is approximately 400 ° C, and this is the beginning of scale formation in structural steel. The walls of the working bath furnace warm up significantly more, respectively, "black" steel, even thicker frit much faster than stainless steel. If you take into account the furnaces of the average price range, then the chromium content in the used steel is 12-13%, which has a positive effect on the cost of the product and on operational characteristics. |

| Category | Name | Price |

|---|---|---|

| Economy class | 1. | 9590 rubles |

| 2. | 9999 rubles | |

| 3. | 10800 rubles | |

| 4. | 18900 rubles | |

| 5. | 23000 rubles | |

| 6. | 17900 rubles | |

| Middle class | 7. | 25850 rubles |

| 8. | 25,000 rubles | |

| 9. | 25600 rubles | |

| 10. | 25,000 rubles | |

| 11. | 25,000 rubles | |

| 12. | 28000 rubles | |

| 13. | 29900 rubles | |

| 14. | 29900 rubles | |

| 15. | 30000 rubles | |

| 16. | 36600 rubles | |

| Premium class | 17. | 43500 rubles |

| 18. | 52,000 rubles | |

| 19. | 69000 rubles | |

| 20. | 96000 rubles | |

| 21. | 89000 rubles |

1. Heat Extra - 9,590 ₽

If you have the opportunity to relax in the bath at least 5-6 hours, then your choice is middle class furnaces. Having experimented with the modes, you can choose the most convenient option, and enjoy a good ferry for relatively small money. In this category, we recommend furnaces from Feringer.

If you want to get a real Russian bath, then do not save the bath stoves with a brick or in talco chloride (or coil) comply with the most stringent standards, and their price only reflects the quality of the performance of products. In this category, we recommend furnaces from.