Everything you need to know about the gearbox and the transfer case of the UAZ. UAZ, gearbox: maintenance eliminate the malfunction of the low gear UAZ

A car consists of many components and assemblies. The transmission is one of the most important components in a car's design. Like any other unit, it needs regular maintenance. Today we will look at how the gearbox is serviced (including UAZ Patriot) on the cars of the Ulyanovsk Automobile Plant.

Appointment

What is this node for?

The task that the gearbox performs on a UAZ car is to change the traction force of the driving wheels (of which there can be four on all-wheel drive) by means of the engagement of different gears. The latter have a different number of teeth. One of them works in reverse - that is, moves the car backward.

Main points when servicing

During the operation of the UAZ vehicle, the gearbox must undergo regular inspection. The first thing to look out for is oil leaks. When lubricant flows from under the car during parking, and characteristic noises and howling occur during movement, it is necessary to urgently check the level of the remaining fluid in the system. If it is new (UAZ), the oil in it changes immediately after running in. Usually it is 2-3 thousand kilometers.

How to do it?

First you need to unscrew the plug from the hole. It should be noted that there are several of them. The first one, located in the middle of the box, is for the bay, and the one below is for draining the liquid. Unscrews, as in most domestic cars, with a hex wrench. Before this, you should prepare in advance a container where the old oil will be drained.

It can be made from an old canister by cutting off the side of it. After draining the fluid, the gearbox (UAZ "Loaf" is no exception) goes through the flushing process.

Flushing

To do this, you need 500-700 milliliters of "mineral water" (not to be confused with water - this is oil).

Screw the hole in from the bottom and pour it into the transmission through the top neck. Let the car idle for a while (4-5 minutes will be enough). Transmission gears must be in neutral. Next, we turn off the engine, substitute our canister and drain the oil by unscrewing the bottom "hatch". Also remember that you cannot drive on, due to its low viscosity - this can lead to scuffing, and, as a result, you will have to repair the UAZ gearbox.

How much to pour?

New liquid must be poured until it starts flowing from the upper "hatch" - this is a signal that the level is at the maximum mark. By the way, the remainder of the liquid is checked according to the same principle - using a hex key, unscrew the upper plug and look at the remainder with a dipstick. Even a wooden twig or a long nail can serve as a probe. The main thing is that the item is clean. If there is not enough oil, add it (but do not mix with different brands). Typically, UAZ vehicles use Lukoil or its analogue, consonant with the name, Yukoil.

How often should the level be checked?

This operation must be repeated at least once every ten thousand kilometers. As we said earlier, if there is a missing level, it must be refilled. By the way, the level is checked only on a cooled transmission - so all the oil will drain into the crankcase.

More about replacement

The operating manual says that after (this also applies to freshly repaired units), it is necessary to change the oil not only in the transmission, but also in the front and rear axles, since we have an all-wheel drive car. The volume of flushing "mineral water" must be at least 75 percent of the total in the unit, which is required by the manufacturer. Ideally, pour until it flows out.

The complexities of the bay

Surely, the owners of UAZs were faced with the problem of the impossibility of filling oil. For this you need to try hard. Fortunately, motorists share their advice, and the procedure becomes much easier. Many drivers recommend using a long metal syringe with a curved rubber nozzle for this. Its capacity should be at least 300 milliliters. We also note that the gearbox requires the use of a viscous oil, so it will be difficult to fill it - it is necessary to “inject” with force. This is especially noticeable in the winter time. Then the gear oil turns almost to jelly. To facilitate efforts, motorists recommend melting this "jelly", that is, preheating it. Fortunately, this is not gasoline, so nothing will burn or explode - you can safely hold the syringe over the gas stove or burner. If there is no such syringe, and the replacement time is running out, then you can use the available methods. UAZ owners are rich in ideas, and everyone invents their own way. For example, to fill in oil, you can use a thin tube and plastic bottle... The car is jacked up and oil is poured by tilting the bottle. It is important to achieve maximum tightness of the connection (meaning the place where the end of the hose touches the neck), otherwise the fluid will not overflow into the transmission, but onto the asphalt. The UAZ gearbox will quickly fail.

Others use a longer tube - pulling it from the transmission filler neck through the bonnet. On upper part a funnel is put on the hose. This method is easier than using a plastic bottle.

Analogue of a metal syringe

Some people use a disposable medical syringe for filling.

Choose a larger volume, since 10 ml can be poured in until the evening. In the absence of an opportunity to buy a large syringe, it is better to use the previous methods.

We carry out maintenance - down with the leak

We have already said at the beginning of the article that the presence of a leak in an element such as a gearbox (including UAZ Patriot) is an unacceptable thing. But what if the transmission regularly “eats” oil? Top up daily to the right level- not the best solution. It is necessary to make repairs - for this, the place of the drip is visually determined and the sealing is changed. It can be a gasket or an oil seal. The repair must be accompanied by a dismantling box.

Why does the box "eat" butter?

There are several reasons for this. Firstly, it is the presence of road dust and dirt in the transmission oil. And as we know, UAZs are bought far from for city driving - in 70 percent of cases they are prepared for a full-fledged off-road, where they conquer fords and rivers. A UAZ, sunk in mud (this is, of course, a rarity, but even four-wheel drive does not save you from a deep swamp) easily “swallows” dirt, sand and water. By the way, the presence of even 5 percent of water can simply kill the transmission. To prevent this, motorists install a cover on the UAZ gearbox. It is able to protect the transmission from such factors.

We treat noise

On UAZ cars, the gearbox often howls, including the transfer case. When the bridge is disconnected, the synchronizers begin to "grunt", strange noises appear. Even after the checkpoint bulkhead, these diseases do not disappear. By the way, it is the transmission lever that is a kind of "noise antenna" on UAZ vehicles - press it down a little with your hand, and the sounds disappear. Of course, driving and constantly pressing the lever will not work (especially since it harms the resource). Therefore, many drivers are advised to install a gearshift lever from a GAZelle. According to legend, the noise level disappears. This is one of the many tips from UAZ owners. By the way, the gearbox diagram of the UAZ and GAZelle is almost the same. Therefore, parts are interchangeable here (including the "noise antenna").

Gearbox UAZ 469 - overhaul

The cost of a new box is about 30 thousand rubles, so many make repairs with their own hands. But first you need to check what exactly is out of order. So, first of all, we look at the state of the gear shift fork.

Even if visually it is "like new", be sure to move it from side to side. If it dangles from the rods, tighten it. Next, we look at the wear of the gears of the gears. The greatest wear can be in the area of the coupling teeth. The gap between them should not exceed 1 millimeter (we use a special probe for diagnostics). If the gap is increased, the teeth will only seize halfway - hence the interruptions in work. Be sure to inspect the input shaft and synchronizers. The guide teeth must be free from bluntness and wear. Rust is also unacceptable. The synchronizer and gears are replaced entirely with new ones.

Then we take out the synchronizer sleeve and the hub. Externally, we inspect the lateral wear from the teeth of the input shaft. The edges must be sharp - with blunt teeth they will slip, so it is very difficult to engage the gear. As for the bearings, noises during their rotation, and even less backlash, are unacceptable. These elements are replaced with new ones.

If during operation the reverse gear was engaged with difficulty and crunching, check the condition of the teeth on its gear. Very often these details are "overwhelmed". The splines of the intermediate shaft must not be "bruised". Otherwise, a replacement. If they are intact, only the bearing changes.

So, we found out how the gearbox is serviced on a domestic UAZ car.

One of the important parts in the device of a car, in addition to the power plant, is the transmission. It provides the transmission of rotation and a change in the gear ratio from the motor to the wheels.

But if the engine has all the systems and mechanisms combined into a single structure, then the transmission consists of separate parts interacting with each other.

The most technologically simple is the transmission with a manual gearbox.

It is this component that is used on almost all domestic cars (only relatively recently, models with automatic transmissions began to appear).

A manual gearbox belongs to a simple transmission, therefore, its reliability indicators are high. But it is also susceptible to malfunctions and there are many of them, not to mention the automatic transmission.

Design features of the transmission of different cars

The transmission of passenger cars can have a different layout, which affects the number of components.

So, on the classic models VAZ-2106, 2107 and others - the drive is rear, so the design of the transmission includes a clutch, gearbox, propeller shaft, rear axle with main gear, differential and semi-axles.

More modern models, the same VAZ-2109 is front-wheel drive, so it does not have a cardan with a bridge, and the main gear with a differential is part of the gearbox design.

But in addition, there are drive shafts with.

And if we consider the design of SUVs - Chevrolet Niva, then their transmission layout includes all the specified elements of a car with front and rear drives, and in addition there is a transfer case that provides rotation to both axles and the ability to turn off one of them.

Transmission malfunctions, signs

The more parts a transmission has, the more likely it is to break. And in each of the components there are many faults.

Clutch.

On all these cars, the clutch has an almost identical design - it is single-disc, "dry".

Without the clutch, it would have been impossible to start moving smoothly during the trip and change the gear ratio at the checkpoint, since this requires disconnecting the motor from the transmission.

Since the clutch is structurally the same, then the faults on all of the listed cars are identical. The only difference is the types of drives.

So, on the VAZ-2106, 2107, as well as VAZ Niva, Niva Chevrolet, UAZ Patriot, a hydraulic drive is used, and in VAZ-2109 - a mechanical, cable one.

If we consider the clutch itself, then its main faults are:

- Wear of the driven disc (friction linings, splines, dampers);

- Wear of the working surfaces of the flywheel and drive disc;

- Damage to dampers, diaphragm release spring;

- Worn release bearing and damage to its drive yoke;

- Incorrect adjustment.

Signs of a clutch malfunction are quite noticeable, and they appear in the form of "slipping", "driving", increased noise under certain operating conditions, jerks when starting to move.

In most cases, to eliminate problems with the clutch, it is necessary to disassemble it, troubleshoot and replace damaged and worn elements.

As for the drive, the VAZ-2109 has not so many breakdowns in it, and they usually boil down to problems with the cable - its rush or biting. Everything is "treated" by the usual replacement.

But there are more faults in the hydraulic drive. In such a drive, a depressurization of the system may occur, damage to the main and working cylinders.

The restoration of working capacity depends on the component in which the problem has arisen. If the system leaks, then it is eliminated by replacing the pipeline with subsequent pumping.

The cylinders are either repaired using repair kits, or simply replaced.

Transmission.

The gearbox is one of the main components of the transmission, and it has the most complex design of all components. Therefore, she has more breakdowns.

VAZ of the classic family (2106, 2107), Sputnik (VAZ-2109, 21099), Niva 21213 and Chevrolet Niva, as well as UAZ Patriot use three-shaft mechanical gearboxes with constant gearing.

And although the checkpoints are structurally different (especially the VAZ-2109 relative to the others), the principle of operation is the same for all of them.

Therefore, the malfunctions of these transmission units on all of the listed cars are, in fact, identical, as well as their symptoms.

If there are problems at the checkpoint, this will certainly manifest itself, and different ways... Signs of breakage in the box are:

- Increased operating noise (in different modes). This problem often arises due to wear of the shaft bearings or synchronizer couplings. But such a malfunction can also appear due to damage to the blocking device, weakening of the gearbox fastening, low level gearbox lubricants, clutch malfunctions;

- Decrease in the clarity of the gearbox shift, difficult gear engagement. Such signs occur in case of severe wear of synchronizers or gears, damage to shift sliders, misalignment or damage to elements of the engaging mechanism;

- Knocking out speed. This problem arises due to wear and damage to a number of components of the box (all the same synchronizers, gears, shift mechanism, etc.);

- Oil leaks occur in case of wear of the gearbox oil seals and loosening of the fasteners of the covers;

- Crunch when shifting gears. Damaged or badly worn gears and synchronizers give such a result, as well as a strong backlash of the shafts;

As you can see, most of the malfunctions are associated with wear and tear of the components of the box.

But it is possible to accurately identify the cause only after dismantling the unit and disassembling it. It is possible to restore the gearbox to work by replacing worn-out components.

There are also more specific breakdowns, although they are much less common. These include the destruction of the body, loosening of fasteners, followed by falling between the gears, etc.

Cardan shafts.

The next element of the transmission is the cardan shafts, which are used to transfer rotation to the VAZ-2106, 2107, as well as Niva 21213, Chevrolet Niva and UAZ Patriot.

But in the case of the first two cars, they have only one shaft in their design, but in SUVs there are two cardan shafts (to transfer power to the two driving axles), in the Nivs there is also an intermediate shaft connecting the gearbox with the transfer case.

The components of these shafts are also damaged and worn out during operation, which leads to a number of malfunctions, which manifest themselves in the form of:

- Knocks when picking up speed. This signals a malfunction of the hinge cross or its bearings, as well as loosening of the shaft fasteners;

- Squeaks (permanent or periodic). This is usually the result of a wedge in the hinge;

- Vibration when driving. It appears as a result of strong backlash in the hinges, imbalance or bending of the shaft itself;

Problems with cardan shafts are eliminated by checking the condition of their hinges and replacing them in case of critical wear, balancing. But often motorists simply change the shaft assembly.

Main bridge.

The main gears with differentials in VAZ 2106, Niva, Niva Chevrolet, UAZ Patriot are an introduced unit and are located in the drive axles (in passenger cars, this is the rear axle, in SUVs, both).

The task of these components of the transmission is to distribute the rotation to the wheels.

Although this unit is relatively simple in design and consists of a small number of elements, it also has malfunctions.

Signs of problems in the operation of the drive axle are as follows:

- Increased noise from the side of the bridge. An increase in noise can occur due to wear of bearings, deformation of the axle beam or axle shafts, wear of spline joints, misadjustment of clearances and the appearance of backlash in the main gear and differential, jamming of satellites and gears with half-shafts;

- Knocks when starting to move. It appears as a result of the appearance of increased gaps in the spline connections or the meshing of the main gears;

- Leakage of grease. Here the fault is the glands used in the construction of the bridge;

Elimination of bridge malfunctions is carried out by disassembling, troubleshooting, replacing worn out and damaged elements with subsequent adjustment of the engagement clearances.

Drive shafts.

As for the VAZ-2109, it does not have a drive axle, and the rotation from the main gear (which is part of the gearbox design) is transmitted to the wheels by means of drive shafts with CV joints.

Note that such drive shafts are used on the front axle in the Niva 21213 and Niva Chevrolet. Also, the CV joint on the Niva is installed on the intermediate shaft.

Regarding the UAZ Patriot, this SUV has a slightly different design. front axle- half-shafts are present, but unlike rear axle, CV joints are installed at their ends.

In such a drive, the "weak link" is precisely the constant velocity joint. This assembly is very sensitive to dirt and damage to the boot always leads to the gradual destruction of the element.

It is not difficult to identify problems with the hinge, because if dirt gets inside it, a distinct crunch will be heard when turning the steering wheel.

In this case, the CV joint cannot be restored and when a sign of its wear appears, it is replaced.

Transfer case.

The last element that is used in the transmission is the transfer case, but this is only available on SUVs.

Its task is to divide the rotation between the two driving axles, and with the possibility of lowering the gear ratio to ensure greater tractive effort on the wheels.

Despite the fact that the device of the transfer case differs from a manual gearbox, their designs use, in fact, the same constituent elements - shafts and gears.

Therefore, the malfunctions at the transfer case are identical to the gearbox, namely, increased noise, unauthorized disconnection of the connected bridge, difficult switching between operating modes (high and low gears).

Note that the UAZ Patriot is equipped with a Dymos transfer case, which is structurally somewhat different from the classic one.

In addition, it is electronically controlled, which makes it even more susceptible to malfunctions, since in addition to mechanical failures, the electronic component may malfunction.

Finally, we note that the most common malfunctions of transmission units are listed here, but in each of them there are other breakdowns that are much less common.

In addition, there are times when malfunctions of completely different components are perceived as transmission breakdowns. For example, knocks in the rear suspension are often identified as problems in the rear axle.

Therefore, in order to identify a malfunction, a thorough diagnostics of not only transmission units, but also closely located auto devices, is imperative.

UAZ cars (loaf) have the most capacious body. The body of the machine is made of durable material. The vehicle is equipped with security systems, a robust power unit that is capable of developing more than 100 horsepower, and a transmission system.

The all-wheel drive passenger-and-freight UAZ, which has increased cross-country ability, began to be mass-produced at the Ulyanovsk Automobile Plant in the mid-1960s.

UAZ transmission components

On the machines of the UAZ - 452 family of the new model, there is a manual transmission (four-speed). Synchronizers of the inertial type provide easy shifting of gears. The five-speed ADS gearbox is synchronized in all forward gears.

A 5-speed manual transmission Daimos (DYMOS) can be installed on the UAZ. This transmission is distinguished by its reliability. The average resource of its work is 300,000 km of run. The filler plug is located in the middle of the box, the drain is at the bottom. It seems possible to unscrew them with a hex wrench. When the oil is drained, a special container should be prepared. New fluid must be filled up to the level of the oil filler hole on the box. The dipstick allows you to accurately determine to what mark the liquid is poured. An alternative to the stylus is a long nail. For preventive purposes, it is necessary to measure the oil level every 15,000 km.

The presence of mechanics on this option vehicle fully justified. It is important to use such a car on rough terrain, off-road. In addition, there will be no towing problems.

The gearbox has external shift levers. The lever in the cab moves freely both parallel and perpendicular to its axis.

The machine is equipped with a transfer case. In the design of the transfer case on the UAZ 452: drive axle shafts, gears. All of the listed components are located in a cast iron crankcase. The crankcase and cover are connected with nuts. The shift fork rods are securely fixed in the cover.

There is a slot, bearings. There is a helical gear wheel for the speedometer drive. The intermediate shaft is fixed on the bearings of the "loaf". This box contains reliable straight-toothed gears.

Thus, the gearbox on the UAZ 452 consists of many components and assemblies. This unit needs regular maintenance.

The need for diagnostics of the UAZ model 452 gearbox

This vehicle must be diagnosed if the control began to deteriorate, characteristic squeaks were heard, when a gear change occurs or the gear began to spontaneously change. The transfer case of the UAZ should be checked if the adhesion of the wheels to the road has noticeably deteriorated, a hum began to appear, and a growing noise during its operation.

During the passage of MOT, the masters must check the system for oil leaks, the level of lubrication. All worn parts in the transmission system must be replaced with new ones. Also, diagnostics involves the implementation of lubrication of the axis of the levers, adjustment of the front rods.

Routine diagnostics in a professional auto repair shop allows you to accurately determine the existing nature of the problem with the box, to eliminate existing problems at an early stage.

Causes of breakdowns

As a rule, the need to replace the main components at the checkpoint arises with their natural wear and tear.

Causes of gearbox breakdowns

The main reason for oil leakage from the gearbox is the presence of an increased fuel level in the system. For gearboxes on UAZ, high-quality oil should be used. If the liquid is not of the proper quality, then this may cause characteristic noises from the side of the box. When the synchronizer or its parts are worn out, a difficult gear change is always noted. Pay attention to the details of the switching mechanism. When the teeth of the gears are deformed, self-switching of gears is often noted.

Gearbox removal process

It is quite possible to carry out repair of the checkpoint on the UAZ 452 with your own hands. This requires:

- a set of wrenches, including the wrenches needed to tighten the nuts;

- screwdrivers;

- hammer;

- chisel;

- pliers.

Dismantling algorithm.

The vehicle must be on level ground. It is necessary to drain the oil from the two boxes by unscrewing the drain plugs. Next, the front seats, the hatch halves, the clutch release fork, the transverse frame, the gearshift levers from the boxes are removed.

The speedometer shaft, suspension mounts in the chassis, and brake levers are to be removed. As a result, the outlet to the clutch housing is opened. The box is fixed on it with fastening nuts, which must be unscrewed, then the UAZ gearbox is carefully extended together with the transfer case until the splined shaft comes out of the flywheel. The driver will need an assistant to remove the box.

Assembling the UAZ gearbox requires proper attention. When self-assembling, the driver may have difficulties with installing the input shaft into the clutch system. During this process, it is necessary to actively move the box so that the shaft falls into the splines.

As soon as the disassembly into separate component parts has taken place, the box must be rinsed in kerosene and dried. All component parts are checked for integrity. First of all, this applies to the crankcase, shafts. If the threads on the shafts are damaged, they must be replaced. The machine is considered dangerous to operate if the gears are chipped.

Thus, timely repair of the UAZ “loaf” checkpoint helps to extend the resource of the box.

A four-speed semi-synchronized gearbox for cars of the UAZ-469 and UAZ-452 families, mechanical, is designed to change the torque transmitted to the drive wheels in order to obtain the best traction and dynamic qualities in these road conditions.

For this, the gearbox has four gears for forward movement and one for reverse movement. The gearbox is equipped with inertial synchronizers to facilitate the inclusion of third and fourth gear.

Specifications four-stage semi-synchronized gearbox UAZ.

- Center-to-center in mm: 80.5

- Maximum torque on the input shaft in kgcm: 17

- Number of pairs of constant mesh gears: 3

- Module of helical gears: 3

- Spur gear module: 3.5

- Slots of the input shaft of the box:

number of slots - 10

outer diameter in mm - 35-0.075, 35-0.160

inner diameter in mm - 26.5-0.52

slot width in mm - 5,385-0.05

- Gearbox weight in kg: 34

- Crankcase filling capacity in l: 1.0

Four-speed semi-synchronized gearbox UAZ-469 and UAZ-452, device.

The gearbox is attached to the clutch housing with four pins screwed into the clutches. The gears of the drive of the intermediate shaft of the second and third gears are helical and are in constant mesh. The input shaft has two bearings. The front bearing is located in the crankshaft seat, the rear bearing in the front wall of the gearbox housing.

The rear bearing is fixed on the shaft with a special nut with a left-hand thread. On the inner side of the crankcase, the bearing is covered with an oil deflector. On the back of the shaft, two gear rings are cut. For ease of installation, the spur gear and part of the tapered surface of the shaft have an arcuate cutout.

The secondary shaft is located behind the primary shaft on the same axis and has two supports. The front shaft support is a set of rollers housed in the input shaft. The rear shaft support is a double row angular contact ball bearing. There is an oil deflector between the bearing and the shaft end.

The intermediate shaft is mounted on two ball bearings in the front and rear walls of the crankcase. The front bearing is fixed on the shaft with a special nut, which is locked by pressing its collar into the shaft groove. The rear bearing has a thrust washer on the outer race. The rear bearing is fixed to the shaft with a washer and a special bolt with a left-hand thread.

The reverse gear block is mounted with a bearing assembly on the axle, which is locked in the crankcase with a special threaded pin from the side of the crankcase hatch. The four-speed semi-synchronized gearbox of cars of the UAZ-469 and UAZ-452 family has the following gear ratios: 1st gear - 4.124, II gear - 2.641, III gear - 1.58, IV gear - 1.00, reverse - 5.224.

Gearbox synchronizers.

Inertial type, the synchronizer mechanism is assembled on the hub. The hub has three rectangular longitudinal grooves to accommodate crackers. A hole is made in the center of each groove in the radial direction.

When assembling the mechanism, springs are installed in the holes of the hub, and steel balls are installed in the holes of the crackers. To avoid the cases of balls falling out, the holes in the breadcrumbs are made stepped. In the synchronizer, the crackers are installed with the side with the holes of the smaller diameter towards the coupling.

Acquisition and selection of synchronizer parts.

Gear shifting mechanism.

It has three shift forks that are connected to the moving elements of the gearbox. All forks are attached to the rods using bolts with a cone at the end. The rods together with the forks move in the axial direction. To fix the neutral position and the engaged gear, the rods have spring clips. A locking device is installed between the rods, which prevents the simultaneous engagement of two gears. One of the rods, brought out of neutral, locks the others.

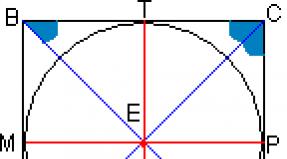

Mechanism for shifting gearboxes on vehicles of the UAZ-469 family.

All shift forks have slots that accommodate the shift lever. Moving the lever across the vehicle axis selects the fork, and moving the lever along the vehicle axis engages the selected gear. Between the grooves of the forks of the first - second and third - direct gears, the lever moves freely.

To insert the lever into the groove of the reverse fork, you need to overcome the resistance of the fuse. The safety device is a mushroom-shaped plunger equipped with a position lock, a return spring and a retaining ring that limits the plunger travel. The fuse is closed from the outside with a cover.

On vehicles of the UAZ-452 family, for gear shifting, two drive levers, a horizontal gear change and a vertical gear selection are installed in the side cover of the gearshift mechanism.

When the vertical lever is rotated, the coupling moves vertically on the shaft and can be installed in one of three positions. In this case, the clutch cam enters the groove of the fork for the required gear. By rotating the horizontal lever, the clutch cam moves with the stem and fork, and engages the gear.

Mechanism for shifting gearboxes on vehicles of the UAZ-452 family.

Reference dimensions of the gear shift forks.

Gear shift lever on vehicles of the UAZ-469 family.

It is installed on the upper flange of the side cover in a special removable support fixed with four screws. A spring is installed under the shift lever in the support, which presses the lever against the support sphere. The lever is secured from turning around its axis by two pins pressed into the lever support and entering its slots. Sealing is ensured by a corrugated rubber cuff. The side cover has a threaded hole for installing the reversing light switch.

The drive levers of the gearshift mechanism for cars of the UAZ-452 family are connected by means of rods and intermediate levers to the control mechanism mounted on the air duct box.

Maintenance of a four-speed semi-synchronized gearbox.

During operation, maintenance of the gearbox is reduced to checking the oil level in its crankcase and replacing it on time, as well as periodically checking all threaded connections. If a leak is found, find out the cause and replace the defective parts (gaskets, cuffs).

Possible malfunctions of the gearbox and shift mechanism.

Noise in the gearbox.

- Loose fastening of the gearbox with the clutch housing and gearbox

- Oil contaminated with solid particles

- The oil does not correspond to the recommended one or its level is low

- Worn or destroyed parts

Difficulty shifting gears.

- leads, as a result of which the synchronizer blocks the transmission

- Parts of the synchronizer are worn out or the ball comes out of the socket

- The gear wheel of the first gear on the secondary shaft is seized due to scoring of the seating surface by burrs formed at the ends of the gear spline from the inclusion of the second gear with blows to the teeth

- Deformed forks and other parts of the shifting mechanism

Self-switching off the transmission when the car is moving.

- Loose fit on centering surfaces as a result of wear or crushing of parts

- Gear bushings are worn out

- Parts are skewed due to bent gear shift forks

- Worn gear teeth

- Axial play of shafts and gears from wear or loosening of fasteners

Oil leaks from the gearbox.

— Elevated level oil in the gearbox

- Foaming of the oil due to poor quality or water ingress

- Loose tightening of parts with gaskets: side cover, shift lever support, box connection connector, input shaft front cover, intermediate shaft cover, or these gaskets are damaged

- Cracks in the crankcase or in the covers

- The stem bore plugs fell out.

The UAZ 469 car, produced by the Ulyanovsk Automobile Plant, specializes in the transportation of people and goods. The cross-country ability of this machine allows you to drive on any roads.

General characteristics

UAZ gearbox

A gearbox is a car's gearbox. UAZ 469 has a mechanical 4-speed gearbox equipped with inertial synchronizers. They are designed to engage gears without noise or rumble. Synchronizers help align the speed of the mating teeth before engaging. The rotation speeds of the motor and the wheels do not match; a synchronizer is needed to align them. In addition, the gearbox allows the machine to move in reverse.

The gearbox of the UAZ 469 checkpoint consists of the following parts:

- input shaft;

- front cover;

- special nut;

- auxiliary fasteners;

- auto-laying;

- ball bearings;

- output shaft drive bearing;

- crankcase;

- clutch for connecting III and IV gears;

- gear wheel of III transfer;

- gear wheel of 2nd gear;

- clutch for connecting 1st and 2nd gears;

- gear wheel of 1st gear;

- secondary shaft;

- fastening washer;

- check point spacer ring;

- mounting bolt;

- washer for fastening;

- intermediate shaft;

- reverse gear axle;

- reverse gear;

- Cork;

- block of gear wheels of the intermediate shaft drive and III gear;

- lid.

UAZ box device

If you are interested in the scheme of the UAZ checkpoint, it is easy to find it in the photos and drawings posted on various sites on the Internet.

4 studs are screwed into the clutch housing, on which the gearbox is attached. The intermediate shaft drive has gears that are in stable meshing. Gears of 1st gear - with straight teeth, 2nd and 3rd - spiral. They are mounted on a drive shaft, supported by needle bearings. The drive shaft has 2 bearings. The role of the clutch when the second gear is engaged is played by the gear of the first. The inclusion of reverse gear and the first occurs due to the movement of the gears. Transmission bearings are ball bearings. To prevent movement along the axis, the gears are secured by rear bearings. The rear bearing of the countershaft is bolted to the shaft itself.

The changeover device has 3 forks fixed to the rods with locking screws and located in the side cover. The ball-shaped stopper of the neutral position and the included gears has a stem. Locksmiths located between the rods do not allow 2 gears to be connected at the same time. The support contains a lever that helps to move the forks. He himself is pressed by a spring to the supporting spherical surface. The boot fitted on the lever prevents water and dirt from entering the device. To prevent accidental engagement of the reverse gear (the driver can simply confuse it), this device contains a fuse - a plunger, which is equipped with a return spring and a ball.

The gearbox lubricator is aligned with the transfer case. The grease from the distributor passes through the double-row bearing (angular contact) and the existing drain device, and then returns through the drain hole.

Repair of the UAZ checkpoint

A manual gearbox is the most important transmission unit of the UAZ 469 car... At the UAZ 469 checkpoint, a responsible and fundamental task is to monitor the variability of the motor torque value and transfer from the engine to the drive wheels of the machine. The UAZ 469 manual transmission has a fairly long service life. This does not mean that the checkpoint does not need to be repaired.

Correct use of the car makes it possible to do without repairs for a long time, but if the operating conditions are not met, the UAZ gearbox assemblies wear out, which inevitably leads to repairs.

Gearbox wear and repair

In what cases does the operation of the machine lead to wear of the parts of the box, as a result of which repair is required?

- Car use in extreme modes.

- Operation of UAZ 469 with a faulty clutch.

- The use of low-quality oils for the drive axle.

- Maintenance of the gearbox by a non-professional.

These are the main prerequisites that can cause urgent repair of the UAZ 469.

To repair the checkpoint, you need a large set of equipment.

- Open-end wrenches in 2 copies (for 10, 12, 13, 14, 17, 19, 22). Using a 14 wrench, unscrew the rear shaft from the transfer case flange. If you misuse this key, you can create huge problems for yourself.

- Socket wrenches.

- Professional flat nut wrench.

- Regular and Phillips screwdrivers.

- Platypus for removing and putting on retaining rings.

- Metal pin for knocking out individual parts.

- To quickly loosen nuts and bolts, you need small segment iron pipe.

- Quality core and chisel.

- Mounting blade.

- Heavy hammer.

- A large number of cans for bolts and nuts to place parts consistently as you work.

- Bearing puller.

- A car owner who is attentive to his car can identify problems with the gearbox.