Processing seed oil vegetable oil. How are vegetable oils obtained and how are they useful? Technology and equipment for the production of sunflower oil

In the total volume of the world market of sunflower oil, which is about 10 million tons, Russian production occupies a fifth. In other words, the production of vegetable oil in our country produces about 2.2 million tons of this product. Not only large enterprises supply sunflower oil to the domestic market. On the contrary, about half of the total volume is produced in small and medium-sized enterprises.

Even by the standards of a small farm, the threshold for entering this business is low. There are also no problems with the sale of the product. If it is not possible to realize the entire produced volume in your region, then the possibilities for export are practically unlimited. The consumers of sunflower oil are not only the population and the food industry. This product is used in the cosmetic, medical and paint industries. Another positive side of production is its zero waste. After pressing the oil, waste remains that are used for livestock feed, from which fuel pallets and so on can be made.

Sunflower oil making process

Sunflower oil production technology is presented below in the form of a table.

| P / p No. | Contents of operation |

| 1 | Sunflower cleaning from organic, inorganic and other types of impurities. For this, aspirators, stone collectors, separators are used. The raw material is blown with air, sifted through several types of sieves. |

| 2 | Sorting of seeds by size, dehulling, peeling, crushing of the core. The seeds are peeled from the husk by the method of impacts, compression, cutting or processing on a rough surface. Which method will be chosen - such equipment must be purchased. |

| 3 | Getting the oil itself. This can be done in several ways, direct extraction and conventional, single, cold or double pressing. |

| 4 | Purification of the product from impurities or refining. Chemical, physical, or combined methods are used. |

| 5 | Spilling oil into containers. Most often it happens automatically on special lines. |

| 6 | Usually the product is filled into polymer bottles. They are labeled and sealed. |

According to the degree of purification, sunflower oil is divided into refined and unrefined. The latter type is a mechanically refined product. Refined oil can be refined in several ways:

- settling;

- filtration;

- centrifugation;

- deodorization.

State standard GOST R 52465-2005 contains a list of seven types of product.

How much does butter making equipment cost?

Modern equipment for the production of sunflower oil allows you to produce everything in one plant. Separators for cleaning raw materials from debris cost about $ 1,500. For an hour, such an apparatus allows you to prepare 1000 kg of raw materials for cleaning.

The cleaning procedure is also called collapse. The cost of the car for this stage is 3 thousand dollars. Its power should be the same as that of the separator. Therefore, these two units must process an equal amount of raw materials at the same time. The number of pairs of these units must meet the raw material requirements of the main spinning line. After crumbling, all products are fed into one bunker. From there it is transported by conveyor to the extraction section. It starts with a roller mill. This equipment grinds the seed kernels. Its cost depends directly on the power. For example, a unit that is capable of processing 800 kg of raw materials per hour costs 13.8 thousand dollars. If you need to combine it with several separators and crumbling machines, then the price will start from 36 thousand dollars.

The line capacity is up to 12 tons / day, the cost is 1,930,000 rubles.

Enterprises equipped with the latest equipment are capable of processing up to 48 tons of raw materials per day. This amount of sunflower can be harvested from 19 hectares of land. Typically, the plant operates in a one-shift mode, but continuous production can be organized during the season.

After grinding, the raw materials go to the braziers. They are divided into two types according to the heating method: steam and fire. Both for the first and for the second method are used gas-burners... Only in the first case the water is heated and steam is formed, and in the second the surface of a large boiler with raw materials is heated according to the principle of a frying pan. The steam frying method allows you to obtain oil that does not have the specific smell of roasted sunflower seeds. Such equipment, capable of frying 800 kg of raw materials per hour, costs from 11.5 thousand dollars.

If you use cold pressing technology, you can exclude heating equipment. However, the oil yield will be much less. Then the raw material goes to the squeezing machine. They cost about 20-28 thousand dollars and are capable of pumping up to 25 tons of raw materials per day through pressing. After the press, the oil is defended for some time. All impurities are precipitated, and the product is driven through special filters. Their price starts at $ 3,000. One filter can clean 160 kg of oil per hour.

Sunflower oil production as a business.

The extraction method for obtaining the product allows you to increase its yield by 2%. At the factory, two methods can be combined. Usually, oil is obtained from waste after pressing. The final cake is called meal and is used to feed livestock. The line for filling the product into bottles costs 13 thousand dollars. It allows pouring 3600 liters of sunflower oil in one shift.

This business will be especially profitable in those farms that grow sunflower on their own. But you can also consider it as a separate production. Then you need to take care not only of the sale of finished products, but also of the purchase of raw materials in the required quantities.

A step-by-step plan for starting a business

In order not to lose capital investments when starting a business for the production of sunflower oil, a detailed analysis of the market in the region where it will be produced is carried out. Then the scheme of action, as for any production, is identical:

registration and purchase of equipment;

procurement of raw materials and hiring personnel;

search for sales channels for finished goods ...

How much can you earn

This business can be said to be waste-free. Here, earnings include not only the sale of the sunflower oil itself, but also husk and meal. The cost of 1 liter is 35 rubles. Meal can be sold for 1.5 thousand rubles, and husk at a price of 9 thousand rubles per ton. If you set up production correctly, then the monthly income will be about 3,000,000 rubles. Less costs, we get a net profit of 2 million rubles.

How to choose equipment

For the full operation of production facilities, you will need to purchase:

oil press and seed roaster;

oil filter and separator.

What OKVED should be indicated for the production of sunflower oil

When choosing a code, look at Chapter C - Manufacturing Manufacturing. It contains a separate code that directly relates to the production of oils and fats - 10.41. It is he who is indicated in all the necessary documents.

What documents are needed to open

The list of required documents is standard. It is best to register as an individual entrepreneur when opening a mini-production (application and state duty, registration and a photocopy of a passport - all documents that must be provided). For legal entities, the list of documents is somewhat expanded. Additionally provided: Articles of Association and the decision of shareholders, information on the presence of a legal address, as well as the director of the company and the chief accountant of the company.

What taxation system to choose for the production of sunflower oil

The best option when choosing a taxation system will be simplified. With her, a businessman will pay an amount of tax equal to 6% of the total profit. Alternatively, upon presentation of documents confirming expenses, 15% of the net profit is paid.

Do I need permission to open

In cases of opening a production at home, you will not need to obtain permits. If a mini-production is opened, then you need to think in advance about obtaining permits in the sanitary and epidemiological station and the fire inspection.

Oil technology

The oil and fat industry is one of the most complex branches of the food industry. It includes oil extraction plants that produce vegetable oils and fats from oilseeds; hydrogenation plants that convert liquid oils into hydrogenated solid oils (fatty oils); workshops for transesterification of oils and fats; margarine factories producing margarine, butter spreads, mayonnaise and cooking fats; soap factories producing toilet and laundry soaps, glycerin and fatty acids; factories for the production of food surfactants (surfactants) and synthetic detergents.

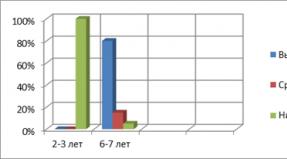

Main raw materials: oilseeds, fruit pulp of some plants (olives), secondary products (corn germ, stone fruit, etc.). Seeds are divided into high oil> 30% fat (sunflower, rapeseed, peanuts), medium oil 20-30% fat (flax, cotton), low oil< 30 % (соя). масло маргарин рафинация

Receiving vegetable oils

Vegetable oil production includes preparing seeds for storage and storing seeds; preparatory operations related to the preparation of seeds for oil extraction; oil pressing and extraction, primary and complex oil purification, meal processing.

A specific feature of the preparation of sunflower seeds for processing is their separation by size, as a rule, into coarse and fine fractions, processed separately according to various technological schemes.

Currently, two methods are used to extract oil from seeds: sequential oil extraction when processing seeds with a high oil content - first by pressing, in which about 3/4 of the total oil is obtained, and then by extraction, with the help of which the rest of the oil is extracted, and single extraction of oil from low-oil seeds by extraction method - direct extraction method.

In addition to the methods of pre-pressing and subsequent extraction and direct extraction, used in large oil and fat enterprises, in recent years, small installations have become widespread on which only one oil extraction (final) is carried out. The press is the main and often the only technological equipment of the mini-plant. Pressing oil from uncrushed, non-crushed seeds, without any preliminary heat or water-heat treatment, allows you to extract from oilseeds only a part of the oil contained in it.

1. Preparation for storage and storage of seeds. The harvesting period for most types of oilseeds lasts 2 ... 3 months. The seeds of most oilseeds are stored with a moisture content that exceeds the optimal values for storage and technological processing. The stored seeds breathe, this leads to the consumption of nutrients, therefore, during storage, the oil content of the seeds decreases, the content of free fatty acids and their oxidation products increases in the oil.

With a decrease in temperature, the intensity of respiration decreases. Cooling seeds to low plus or small minus temperatures by blowing cold air through the seed mass has a beneficial effect on their quality even when storing seeds with moisture above critical.

One of the promising ways of storing wet seeds is storage in controlled gas environments containing oxygen (1 ... 2%) and nitrogen (98 ... 99%). The almost complete absence of oxygen inhibits the respiration of the seed mass, as a result of which the quality of the seeds can be preserved.

When preparing oil seeds for storage, it is necessary to reduce their moisture content to a level below the critical one. The most common method of reducing the moisture content of seeds before storage is heat drying, during which the seeds are heated using a drying agent (usually a mixture of air and flue gases). The dried seeds are then cooled by blowing atmospheric air through them.

2. Hulling of seeds. When processing many oil seeds and fruits, the fruit and seed coats are separated from the main oil-containing tissues - the kernels.

The separation of the shells from the kernel consists of the operation of destroying the integumentary tissues of the seeds - crumbling and subsequent separation (winnowing) of the resulting mixture - rushanka into a kernel and husk (husk). The destruction of the shell should not be accompanied by crushing or destruction of the core. Methods of collapse by blow, friction, cutting.

The quality of the seed collapse (the quality of the rushanka) is characterized by the content of undesirable fractions in it - whole seeds and partially destroyed ones, the so-called whole or undercutting, crushed kernels (chaff) and oil dust. The presence of whole and partially destroyed seeds increases the husk content of the kernel, the presence of chaff and oil dust increases the loss of oil with the separated husk.

3. Grinding seeds. To extract oil from seeds, it is necessary to destroy the cellular structure of their tissues. The end result of the grinding operation is the conversion of the oil contained in the seed cells into a form available for further processing. The required degree of grinding is achieved by applying mechanical forces to the processed material, producing crushing, splitting, abrasive or impact actions. Grinding is usually achieved by a combination of several types of these forces.

The material obtained after crushing the seeds is called mint.

Well-crushed mint should consist of particles of uniform size passing through a sieve with holes 1 mm in diameter, should not contain intact, undisturbed cells, and at the same time, the content of very small (mealy) particles in it should be low.

To obtain mint, roller machines are used. The working bodies of the machine are five rolls located one above the other; the upper roll is corrugated, the rest are smooth. All rolls are fixed to the bed.

4. Water-heat treatment of mint. Oil adsorbed as thin films on the surface of the mint particles are retained by surface forces. For effective oil extraction, the mint hydrothermal treatment is used. With moistening and subsequent heat treatment of the mint, the bond of lipids with the non-lipid part of the seeds - proteins and carbohydrates - weakens, and the oil passes into a relatively free state. Then the mint is heated to higher temperatures, the viscosity of the oil decreases markedly, at the same time the moisture content in the mint decreases, and a partial denaturation of proteins occurs, which changes the plastic properties of the mint. The mint turns into pulp.

In a production environment, the preparation of the pulp consists of two stages. The first one - moistening the mint and initial heating - is carried out in inactivators or steaming-humidifying screws. Intensive short-term heating of the mint to a temperature of 80 ... 85 ° C with simultaneous moistening up to 8 ... 9% (for sunflower seeds, flax) contributes to the uniform distribution of moisture in the mint and partial inactivation of hydrolytic and oxidative enzymes of the seeds, which degrade the quality of the oil. The second stage - heating the mint to 105 ° C and drying it to the final moisture content (5 ... 6%) - is carried out in braziers. Fryers for cooking pulp are divided by design into vats, drum and screw.

- 5. Oil extraction by pressing. The oil is squeezed out in screw presses of various designs. Pre-pressing is carried out using a forepress, and the final pressing is carried out with an expeller. During pressing, the pressure is increased gradually, because with a sharp increase in pressure, the pores are pressed in, and the output of oil is reduced. In order to increase the oil yield during the pressing process, the temperature of the processed material is increased, preventing it from overheating. When overheated, undesirable processes occur: oil oxidation and the transition of protein substances into oil. It is impossible to achieve complete degreasing of the pulp using the pressing method, since thin layers of oil always remain on the surface of the cake leaving the press, held by surface forces that are many times higher than the pressure developed by modern presses. On presses developing maximum pressure and working with maximum oil removal, cake with oil content of 4 ... 7% is obtained. On presses of preliminary pressing - forpress, the most widely used in industry, cake with oil content of 15 ... 17% is obtained.

- 6. Oil extraction by extraction. Provides almost complete oil recovery.

Before extraction, the prepress cake is structured, giving it the structure of crumbs, granules or petals, which ensures maximum oil extraction by the solvent.

As solvents for the extraction of vegetable oils, extraction gasoline with a boiling point of 63 ... 75 ° C and an oil solvent (nefras) with a boiling point (65 ... 75 ° C) are used.

As a result of the extraction, a solution of oil in a solvent (miscela) and a fat-free material (meal) are formed.

The extraction of vegetable oils is most often carried out by the method of immersing the extracted material in a countercurrently moving solvent under conditions of absolute counterflow or by the method of multi-stage irrigation of the material with a solvent under conditions of relative counterflow, when only the solvent moves, and the extracted material remains at rest on a moving belt, in a moving bucket, section of the rotor and others. Advantages of extraction by immersion: high extraction rate, short duration of the process, simplicity of the design of the extraction apparatus and high utilization of its geometric volume (up to 95%). The latter excludes the possibility of the formation of an explosive mixture of air and solvent vapors in the extractor. The disadvantages of this type of extractors include a low concentration of the final miscella (15 ... 20%), a high content of impurities in the miscella, and large dimensions of the extractor in height.

Advantages of multi-stage irrigation extraction: obtaining pure, highly concentrated miscella (35 ... 40%); disadvantages: a longer extraction process, a low utilization factor of the geometric volume of the extractor (45%) and the possibility of the formation of explosive mixtures of solvent vapors and air inside the apparatus, a complex design of the extractor.

To clean the miscella from solid impurities, sedimentation tanks, hydrocyclones and fabric filters are used. If the content of impurities in the miscella is low, then the miscella is purified by passing it through an electrolyte solution (5% NaCl solution).

Distillation of miscella. Miscella consists of a low-boiling solvent and a practically non-volatile oil. At low concentrations of oil in miscella, the solvent is evaporated under normal conditions. As the concentration of oil in the miscella increases, its boiling point rises very quickly. To reduce the distillation temperature and accelerate the process, solvent distillation under vacuum, as well as with water vapor, is used. Distinguish between spray distillation, film distillation - in falling and rising film and layer distillation.

In industrial installations, the distillation of miscella is carried out in a two- and three-stage scheme. The installation for three-stage distillation consists of two film distillers (first and second distillation stages) operating in series at atmospheric pressure (temperature 80-90 єС, oil concentration 75-80%), and the final one operating under vacuum (residual pressure 0.04. .0.06 MPa, temperature 110-120 єС).

The quality of the oil during the distillation of miscella depends both on the technological parameters of the process - the final temperature of the oil and the duration of the treatment of the miscella, and on the content and composition of lipids extracted during extraction from the extracted material - phospholipids, carotenoids and other fat-soluble pigments, vitamins and provitamins, and also products of lipid oxidation, etc. The thermal effect on these groups of lipids leads to their change and not only reduces the quality of the oil, but also significantly complicates the distillation of miscella. Of particular importance is the problem of removing before distillation the fat-soluble pigment of cotton seeds - gossypol, which, when heated, undergoes various chemical transformations and forms products that are difficult to remove from oil. To remove gossypol, the miscella is subjected to alkaline refining before distillation.

7. Refining oils and fats. The process of oil purification from unwanted lipid groups and impurities is called refining, the ultimate goal of which is the extraction of triacylglycerides from natural oils and fats, free from other lipid groups and impurities. Refining is not always carried out until all structural lipids and impurities are completely removed, with the exception of mechanical impurities and water, the removal of which is mandatory already during the primary oil refining.

Purification methods: physical (filtration, sedimentation, centrifugation), chemical (hydration, acid and alkaline refining), physicochemical (distillation, deodorization, adsorption).

Removal of suspended solids and water from the oil is carried out by settling in sedimentation tanks, mechanical dry traps, using sedimentation centrifuges and by filtering through cloth on frame filter presses.

Full refining is carried out when obtaining salad oil used for direct consumption in food, for oils and fats used in the production of margarine, confectionery, cooking fats and mayonnaise.

Rice.

Hydration is the removal of a group of substances with hydrophilic properties from the oil using water, the most important of which are phospholipids. Phospholipids are nutritionally valuable compounds with antioxidant properties. During storage of oils, they fall out in the form of a readily decomposing sediment, which complicates a number of technological operations for oil processing. Therefore, phospholipids are isolated from oil by hydration, and then used as an independent product for food, feed and medicinal purposes.

The hydration process consists in mixing the heated oil with a metered amount of water or other hydrating reagents (aqueous solutions of NaCl and surfactants). In this case, phospholipids form hydrophilic particles with water, lose their ability to dissolve in fat and precipitate (hydration fus). Optimum temperature for hydration of oils: sunflower - 45 ... 50 ° С, soybean - 65 ... 70 ° С; the amount of water added to the oil is also different: for sunflower oil 0.5 ... 3.0% by weight of oil, for soybean oil - up to 6%.

Freezing (winterization) is the removal of waxes and wax-like substances from the oil. The essence of the process lies in the slow cooling of the oil to 10 ... 12 єС with weak stirring in the exporter - a cylindrical apparatus equipped with a frame stirrer. The oil is kept in the display for 4 ... 6 hours. Here, the waxes dissolved in the oil crystallize. Then the oil is heated to 16 ... 18 ° C to reduce its viscosity and filtered on frame filter presses. To speed up the process, auxiliary powders (diatomaceous earth, perlite, etc.) are applied to the filtering surface, which improve the drainage properties of the sediment.

Neutralization of oils with alkali is based on the treatment of refined oil with aqueous solutions of NaOH, during which free fatty acids interact with alkali to form aqueous solutions of soap - soap stocks.

Soap stocks are insoluble in oil and, since their relative density is higher than that of oil, they form sediments, which are then separated from the oil in separators.

The neutralization temperature is 85 ... 90 ° C, the alkali concentration is from 70 to 150 g / l and the excess of alkali from the theoretical amount is 5 ... 20%, depending on the acid number of the oil supplied for neutralization.

Oil refining (neutralization) in miscella is efficiently carried out at an optimal miscella concentration of 35-45%. The miscella leaving the extractor with a lower concentration is either first evaporated in the first distillation stage, or a pre-pressed oil obtained from the same seeds is added to the miscella. Miscella of optimal concentration (35-45%) at a temperature of 20-22 ° C enters the jet mixer, where it is mixed with alkali. A mixture of miscella, soap flakes formed by the interaction of alkali with free fatty acids of oil, phospholipids, gossypol and other substances is heated to 60-70 ° C and treated with demineralized water at a temperature of 90-95 ° C in continuous settling tanks, while separating from the oil water-soluble soap stock. From here, the purified miscella enters the second stage distillers. Distillation of solvent from soap stock is carried out in a column. The column is operated under vacuum. The soap stock heated to 110 ° C with the solvent is discharged through the nozzles into the steam space of the column, the solvent evaporates, and the soap stock goes to the warehouse.

Distilling off the solvent from the meal. The meal leaving the extractor contains from 20 to 30% of the solvent, which is removed by heating in vat evaporators (toasters).

The solvent removed during the processing of miscella and meal is recovered by condensation from steam-gas mixtures in heat exchangers-condensers, and then returned to production.

The meal intended for use as animal feed is subjected to granulation, pre-mixing it with a hydrofuse - a mass precipitated when processing press and extraction oils with water, or with soap stock - a sediment that is obtained when treating miscella or vegetable oil with an alkali solution.

Obtaining protein isolates from meal. The protein is removed from the meal, first with an aqueous solution of NaCl, then NaOH. The insoluble precipitate is separated, and the extract containing 2-3% protein is purified and precipitated with HCl. The precipitated protein is washed and dried in a spray dryer with air at a temperature of 180-200 ° C.

Ready protein with a moisture content of 3-8% is packaged and sent to consumers. The total protein yield is 20-25% by weight of the meal. The insoluble residue of the meal after drying is used for animal feed.

Oil bleaching (adsorption refining) - removal of fat-soluble pigments from oil - carotenoids, chlorophylls, and for cottonseed oil also gossypol and its derivatives are provided for vegetable oils (except sunflower) intended for hydrogenation and production of margarine products. To bleach oils, bleaching bentonite clays and activated carbon activated by acid and heat treatment are used. The main component of bentonite clays are aluminosilicates Al 2 O 3 and SiO 2, which include alkali and alkaline earth metals.

When bleaching in oil, undesirable processes occur: isomerization of fatty acids, which reduces the biological value of the oil; the formation of fatty acids with conjugated double bonds, which leads to the activation of oxidative processes in the bleached oil during storage. To reduce oxidative processes in oil, the bleaching process is carried out under vacuum.

Deodorization of oils - removal of odorizing substances from oil - low molecular weight fatty acids, aldehydes, ketones and other volatile products that determine the smell and taste of the oil, as well as the release of unwanted foreign compounds from vegetable oils - polycyclic aromatic hydrocarbons, pesticides, toxic products - aflatoxins, etc. dr.

The boiling point of oil and aromatics is very different, therefore, deodorization is carried out by distillation under vacuum.

Vegetable oils are obtained from fruits, seeds, roots and other parts of plants, mainly oilseeds. Vegetable oils are also found in the seeds of some fruit trees (apricot, peach, cherry, sweet cherry, almond), grape seeds, watermelon, tomatoes, tobacco, tea, as well as in various oil-containing food waste (bran and germ of cereal seeds - wheat, corn).

Composition and useful properties of vegetable oil

Vegetable oils are mainly (95-97%) composed of fats (triglycerides), which, along with carbohydrates and proteins, are one of the important components of nutrition and perform structural and energy functions.

The remainder is made up of waxes and phosphatides, as well as free fatty acids, lipochromes, tocopherols, vitamins and other substances that impart color, taste and smell to oils. They also contain a number of substances that are important for the life of the human body, moreover, the body is not able to synthesize these substances on its own.

These substances include:

Linoleic acid;

Linolenic acid;

Phospholipids.

Linoleic and linolenic acids are polyunsaturated fatty acids. They are structural elements of cell membranes and ensure the normal development and adaptation of the human body to adverse environmental factors.

Linseed and hemp oils have the highest content of these acids. Sunflower, poppy, nut oils dry out weaker and slower. Rapeseed and olive oils, containing only traces of linolenic acid, lack the ability to dry (however, olive oil thickens). Castor oil does not dry out or thicken.

Phospholipids are the main component of cell membranes. They are involved in the regulation of cholesterol metabolism and contribute to its excretion. The optimal content of phospholipids in the diet of an adult is 5-7 g / day.

It should be noted that vegetable oils cannot contain cholesterol, however, some manufacturers, for advertising purposes, emphasize on their product labels that this oil does not contain cholesterol. And this in itself is absurd.

How are vegetable oils obtained?

Pressing and extracting are the two main ways to obtain vegetable oil. Oil in production can be obtained only by pressing, jointly pressing and extracting, or only by extraction.

Oil squeezing (pressing seeds to obtain oil) resembles the work of a meat grinder. This is a more environmentally friendly method, but the oil yield is less. The resulting oil is already unrefined. But nevertheless, it is additionally subjected to filtration to give it a marketable appearance, to obtain a transparent light oil without sediment, to which the consumer is accustomed.

The cake after pressing the oil can be subjected to extraction in order to obtain the remaining oil, therefore, most often the process of pressing and extraction occurs together. The production of sunflower oil by the extraction method involves the use of organic solvents (most often extraction gasolines) and is carried out in special devices - extractors. During the extraction, miscella is obtained - a solution of oil in a solvent and a defatted solid residue - meal.

The extraction method for the extraction of oils is more economical, since it allows the maximum extraction of fat from raw materials - up to 99%. After extraction, the solvent is removed from the oil. The finished oil is settled, filtered and subjected to further mandatory processing.

What is vegetable oil refining?

To increase the nutritional value and technological properties of oils and fats, they are subjected to varying degrees cleaning - refining.

Refining is some of the most important technological processes processing of fats (oils) in order to remove impurities from them and those accompanying substances that reduce the quality and technological properties.

Refined oil is practically tasteless and odorless. This oil is also called impersonal. Its nutritional value is determined only by the presence of essential fatty acids (mainly linoleic and linolenic), which are also called vitamin F. This vitamin is responsible for the synthesis of hormones, maintaining immunity. It gives stability and elasticity blood vessels, reduces the body's sensitivity to the action of ultraviolet rays and radioactive radiation, regulates the contraction of smooth muscles, and performs many more vital functions.

Vegetable oil can get on the shelves in the following form:

Unrefined oil: may be with sediment or suspension (but it has been filtered); retains the smell, taste and color inherent in a particular type of oil, depending on the oilseed raw materials from which it is produced (sunflower, linseed, olive, etc.);

Refined non-deodorized oil: outwardly transparent, but with a characteristic taste, smell and color;

Refined deodorized oil: clear, light yellow, odorless and tasteless, inherent in unrefined oil.

There are several stages of refining in the production of vegetable oil.

- Getting rid of mechanical impurities - settling, filtration and centrifugation, after which the vegetable oil goes on sale as commodity unrefined.

- Phosphatide removal or hydration - treatment with a small amount of hot (up to 70 ° C) water. As a result, protein and mucous substances, which can lead to rapid deterioration of the oil, swell, precipitate and are removed. Such processing makes the vegetable oil more transparent, after which it is called commercial hydrated. But it is practically not presented on the shelves.

- Neutralization is the impact on the heated oil with a base (alkali). This step removes free fatty acids that catalyze oxidation. Heavy metals and pesticides are also removed during the neutralization stage. If the content of these acids is excessive, the vegetable oil develops an unpleasant taste. The vegetable oil that has passed these three stages is called already refined, non-deodorized.

- Bleaching - treatment of oil with adsorbents of natural origin (most often special clays) that absorb coloring components, after which the oil is clarified. Pigments pass into oil from seeds and also threaten with oxidation of the finished product. After bleaching, the content of pigments in the oil decreases and it becomes light straw.

- Deodorization - removal of substances that determine the taste and smell of oil or flavoring substances by exposing the oil to hot dry steam at a temperature of 170-230 ° C in a vacuum. During this process, the substances that give the oil taste and smell are removed. Deodorization extends the shelf life of the oil. But it should be noted that as a result of this process, a small amount of vitamins are also removed, because any processing is a loss of not only harmful, but also useful substances.

- Freezing - removal of waxes. All seeds are covered with wax, this is a kind of protection from natural factors. Waxes add turbidity to the oil, especially when sold on the street during the cold season, and thereby spoil its presentation. During the freezing process, the oil turns out to be transparent.

After going through all the stages, the vegetable oil becomes impersonal. Margarine, mayonnaise, culinary and confectionery fats are made from such a product; it is used for canning. Therefore, it should not have a specific taste or smell, so as not to disturb the overall taste of the product.

Characteristics of products, raw materials and semi-finished products. Vegetable oils are complex mixtures of organic substances - lipids secreted from plant tissues (olives, sunflowers, soybeans, rapeseed, etc.). According to their composition, lipids are divided into two groups: simple and complex. The main components of simple lipids are fats, which make up 95 ... 97% of lipids. The composition of fats consists mainly of triglycerides - viscous liquids or solids with a low (up to 40 ° C) melting point, colorless and odorless, lighter than water (at 15 ° C density 900 ... 980 kg / m 3), non-volatile. They are highly soluble in organic solvents and insoluble in water. Fats also contain saturated and unsaturated acids and waxes. Phospholipids are important components of complex lipids.

Vegetable fats and oils are indispensable components of food, a source of energy and plastic material for a person, a supplier of substances necessary for him, which are involved in the regulation of metabolism, blood pressure, excretion of excess cholesterol from the body, etc. The most important components of fats are polyunsaturated acids - linoleic and linolenic. They are not synthesized in the human body and are called essential or essential acids. Prolonged restriction of essential fatty acids in the diet leads to physiological abnormalities: the activity of the central nervous system is disrupted, the body's immunity decreases, and life expectancy is reduced. But excess fat intake is also undesirable, it leads to obesity and cardiovascular disease.

The following types of vegetable oils are produced in Russia: refined (deodorized and non-deodorized), hydrated (superior, I and II grades), unrefined (superior, I and II grades). Only refined deodorized oil, which is packed in glass or plastic bottles, should be sent to the retail network and to catering establishments.

According to the standard, the finished oil determines the physicochemical indicators of the permissible content of harmful substances, the amount of moisture, the values of acid and iodine numbers, etc., as well as organoleptic indicators: transparency, smell and taste.

The recommended fat content in the human diet is on average 100 ... 108 g per day, including directly in the form of fats 50 ... 52 g. The optimal chemical composition of food in terms of fats is ensured when 1/3 of vegetable and 2/3 of animal fats are used in the diet.

The raw materials for the production of vegetable oils are mainly oilseeds, as well as the pulp of the fruits of some plants. According to the oil content, the seeds are divided into three groups: high oil (over 30% - sunflower, peanuts, rapeseed), medium oil (20 ... 30% - cotton, flax) and low oil (up to 20% - soy). In Russia, the main oilseed crop is sunflower. Sunflower seeds with an oil content of 40 ... 50%, a moisture content of 6 ... 8%, a content of trash no more than 3% are supplied to production.

Features of production and consumption of finished products. The processing of sunflower seeds into vegetable oil provides for the implementation of the processes of crushing and crushing of seeds, hydrothermal processing of mint, extraction and refining of oil.

ABOUT THE FAMILY Oil reserves in the tissues of oil seeds are unevenly distributed: the main part is concentrated in the seed nucleus - in the embryo and endosperm. Fruit and seed coats contain a relatively small amount of oil, which has a different (worse nutritional value) chemical composition. In this regard, the shells are separated from the main oil-containing tissues by destroying the integumentary tissues of the seeds - crumbling and subsequent separation of the resulting mixture - rushanka into a kernel and husk.

The most important requirement for the breaking operation is that the destruction of the shell should not be accompanied by crushing of the core. The quality of the rushanka is characterized by the content of undesirable fractions in it - whole and partially destroyed seeds, the so-called whole and undershed, crushed kernels (chaffs) and oil dust. The presence of such fractions increases the contamination (huskiness) of the kernel, increases the loss of kernel particles with the separated husk.

The division of the rushanka into kernel and husk is based on the difference in their size and aerodynamic properties. Therefore, firstly, fractions of dewdrop are obtained, containing kernels and husks of the same size, and then, in a stream of air, the rushanka is divided into kernels and husks. The quality of the operation of dushanka separation is assessed by the value of the residual husk content in the finished kernel and the loss of oil with the separated husk.

Smelling family The oil is contained in the intracellular structure of the seed nucleus, which must be destroyed in order to excrete oil. The required degree of crushing is achieved by the action of mechanical forces on the processed material, producing crushing, splitting, abrasive and impact actions. Grinding is usually achieved by a combination of several types of these forces.

The semi-finished product obtained after grinding is called mint and has a very large specific surface, since in addition to the destruction of the cell membranes during grinding, the intracellular structure of the oil-containing part of the cell is also disrupted, a significant proportion of the oil is released and immediately adsorbed on the surface of the mint particles.

Well-crushed mint should consist of particles of uniform size passing through a sieve with holes of 1 mm, should not contain intact, intact cells, and at the same time, the content of very small (mealy) particles in it should be low. The end result of the grinding operation is the conversion of the oil contained in the seed cells into a form available for further technological influences.

G i d r o t e r m i ch and i o work. Oil adsorbed in the form of thin films on the surface of the mint particles are retained by significant surface forces. These forces can be significantly weakened by moistening and subsequent heat treatment of the mint.

Intense short-term heating of the mint with simultaneous moistening contributes to the uniform distribution of moisture in the mint and partial inactivation of hydrolytic and oxidative enzymes in the seeds, which degrade the quality of the oil. The mint is then heated and dried. As a result of this treatment, the mint turns into a pulp prepared for oil extraction.

E n e c e m a l. In the practice of production of vegetable oils, there are two fundamentally different methods of extracting oil from vegetable oil-containing raw materials: mechanical extraction of oil - pressing and dissolving oil in volatile organic solvents - extraction. These two methods of producing vegetable oils are used either alone or in combination with one another.

At present, oil is extracted first by using a pressing method, in which ¾ of the total oil is obtained, and then by an extraction method, by which the rest of the oil is extracted.

The oil is squeezed out in screw presses of various designs. The pressure developed by the screw press reaches 30 MPa, the degree of compaction (compression) of the pulp is 2.8 ... 4.4 times. In this case, the particles of the pulp come closer, the oil is squeezed out, and the pressed material is compacted into a monolithic mass of cake.

It is impossible to achieve complete degreasing of the pulp using the pressing method, since thin layers of oil always remain on the surface of the cake particles leaving the press, held by the surface layers many times higher than the pressure developed by modern presses. Even on presses operating with maximum oil removal and developing high pressure, receive cake with oil content of 4 ... 7%.

Extraction - the extraction of oil from the cake, produced with the help of solvents. As solvents for the extraction of vegetable oils, extraction gasoline and nefras with a boiling point in the range of 63 ... 75 ° C are used. The oil that is on the surface of the opened cells, when washed with gasoline, easily dissolves in it. A significant amount of oil is found inside unopened cells or inside closed cavities (capsule). Recovery of this oil requires the penetration of the solvent into the cell and capsule and the release of the solvent into the environment. This process occurs due to molecular and convective diffusion.

As a result of extraction, a solution of oil in a solvent, called miscella, and a defatted material, meal, are obtained.

To remove mechanical impurities from the miscella, it is filtered. Thereafter, it consists of a low-boiling solvent and a practically non-volatile oil. In the oil and fat industry, the operation of stripping off the solvent is called distillation. With relatively low oil concentrations in miscella, the solvent removal process is initially reduced to a conventional evaporation process. As the concentration of the oil increases, the boiling point of the miscella rises very quickly. In this regard, to reduce the distillation temperature and accelerate the process, solvent distillation under vacuum, as well as with water vapor, is used.

R and f and n and c and I m a s l and. Refining is the process of purifying oil from unwanted lipid groups and impurities. Due to the variety of physical and chemical properties of lipids that make up natural oils and fats, modern refining is a complex process that includes a sequential chain of technological operations that differ in the nature of chemical and physical effects on the removed lipid groups.

The volume and sequence of refining operations depend on the type and purpose of the oil. Hydration is used to remove from the oil with the help of water a group of substances with hydrophilic properties (phospholipids, mucous and protein substances), which precipitate during storage of the oil. The neutralization of the oil with alkali allows it to be purified from free fatty acids capable of saponification. Cooling the oil is necessary to freeze the waxes and separate their crystals. Deodorization of oils is a distillation process to remove volatile substances that determine the smell and taste of the oil, as well as foreign compounds, pesticides and toxic products.

When all the above operations are performed, changes occur chemical composition and the physical state of unwanted substances, as a result of which they are converted into solid particles and suspensions. They can be removed from the oil by various physical methods of mechanical refining: filtration, settling and centrifugation.

A prerequisite for the applied technological operations is the preservation of the triacylglycerol part of the oil, which has nutritional value, in its native state.

Complete refining is necessary to obtain salad oil for direct consumption, for oils and fats used in the production of margarine, confectionery, cooking fats and mayonnaise.

The meal obtained as a result of the extraction processing of the cake is also purified from the solvent by distillation and is used as animal feed. Food protein can be extracted from the meal using a special technology.

When hydrating sunflower oil of the highest and I grade, a food phosphatide concentrate is obtained, containing 40 ... 70% of a surfactant - lecithin and used as an emulsifier, and upon hydration of grade II oil, a feed phosphatide concentrate is produced.

Soap stock, formed during alkaline neutralization of oil, is used in the production of soap.

Stages of the technological process. The production of vegetable oil from sunflower seeds consists of the following stages and basic operations:

- acceptance of seeds and their cleaning from impurities;

- dehulling of seeds, separation of kernels and husks;

- crushing seeds and hydrothermal treatment of mint;

- pressing the pulp and cleaning the press oil;

- structuring the cake and extracting oil from it;

- distillation of miscella;

- oil refining: hydration, neutralization, deodorization, cooling, mechanical purification of impurities;

- distillation of the solvent from the meal;

- packaging of finished oil into consumer and shipping containers.

Characteristics of equipment complexes. The line starts with a set of equipment for cleaning seeds, consisting of scales, silos, separators, magnetic catchers, feed bins, bucket elevators and conveyors.

The next set of equipment for obtaining a seed kernel, which includes centrifugal crushing machines, seed beads, aspiration systems, sifting, bucket elevators and conveyors.

The leading equipment complex of the line is intended for the production of pressing oil, including roller mills, an inactivator, an oil press, filters and pumps, as well as equipment for grinding the prepress cake and the final extraction of oil from it.

The complex of equipment for the extraction of extraction oil includes a crusher and a flattening machine for prepress cake, an extractor, filters for miscella, heaters and distillers, a refrigerator for oil, conveyors, pumps and containers, equipment for stripping solvent from meal, and equipment for solvent purification. ...

The complex of equipment for complete oil refining contains a hydrator, neutralizer, bleaching and drying apparatus, filters, deodorizer, pumps and collectors.

The final complex of the line includes dosing devices, machines for filling butter and packing products into shipping containers.

The machine-hardware diagram of the line for the production of vegetable oil from sunflower seeds is shown in Fig. 2.11.

The device and principle of the line. Sunflower seeds entering production are freed from ferromagnetic impurities on a magnetic separator, weighed, then with a screw conveyor 1 are fed to the air sieve separator 2 for cleaning from mineral and organic litter (Fig. 2.11, a).

Large litter coming from the upper (sorting) sieve, screw conveyor 5 removed from production. Fine litter passing through the bottom (under-sowing) sieve and leaving the cyclones 3 aspiration system of separators equipped with fans 4 , also by screw conveyor 5 removed from production. The content of oil-bearing impurities in the waste litter is not more than 3%.

The seeds, cleaned from coarse and fine litter on sieves, go to the vibrating chute of the separator's pneumatic separation channel 2 ... When air passes through the flow of seeds, light impurities are released from the mass of seeds and are carried out by air through a pneumatic separation channel and air ducts into a sedimentary device - horizontal cyclones. They are designed for preliminary cleaning of the air flow from impurities released from sunflower seeds in the separator's pneumatic separation channel. From horizontal cyclones, light impurities are fed through the anti-suction channel to the screw conveyor 5 .

Air leaving horizontal cyclones is additionally cleaned in cyclones 3 , the separated impurities from which are also removed by the screw conveyor 5 .

Peeled sunflower seeds from a pneumatic separation channel with a scraper conveyor 6 , noria 7 , screw conveyor 9 are fed for caving into centrifugal crushing machines (crumbling machines) 10 ... Before the seeds enter the debris by gravity from the noria 7 into the conveyor 9 installed magnetic separator (iron separator) 8

The seeds, having received acceleration on a centrifugal rotating disk, fall into the radial guide channels of the cuttings, lined with liners made of wear-resistant ceramics, from where they are thrown onto the annular deck, hit against it with a sharp or blunt end of the seed (i.e., they receive a blow in the weakest direction - along the long the seed axis, which basically provides the best caving effect). When hitting the deck, the largest part of the seeds collapses and, in the form of a rushanka, enters a cylindrical sieve located inside the rushka cyclone. When the rushanka moves, down the sieve, part of the oil dust is separated from the rushanka, which is removed from the rushka by a screw conveyor 14 on the screw conveyor core 22 where it mixes with the core.

Sunflower seeds (rushanka) tumbled in rushka consist of whole kernels, their large particles, chaff, oil dust, whole seeds, undershortening, husks of various sizes and litter (vegetable and mineral). Rushanka with a content of whole and undershed up to 25%, oil dust up to 10%, chaffs up to 12% by gravity flows into the seed weeds 16 15 .

The main purpose of the seedlings is to separate the required amount of husk from the rushanka with minimal loss of oil with the husk. At the same time, a part of the remaining litter is removed from the seed plants.

Separation of the fallen sunflower seeds into fractions takes place in the seed vines. Rushanka, passing through the seed grain sifting, is divided into six fractions, of which five are fed to the wake, and the sixth is removed from the machine, bypassing the wake. Each of the five fractions of the product supplied to the wake enters the chamber intended for it, where the product is winnowed with an air stream and the husk is separated from the kernel according to the difference in aerodynamic characteristics.

Kernel with husk content of not more than 12% from the second-fifth sections of seed beads 16 screw conveyors 22 , 48 49 for grinding. Before the core enters the rolling mills on gravity from the conveyor 22 into the conveyor 48 iron separator installed 47 to remove metal impurities.

When crushing sunflower seed kernels, the main goal is to achieve complete destruction of the cellular structure of the nucleus, which contributes to a more complete extraction of oil by both pressed and extraction methods. The optimum moisture content of the nucleus, at which the maximum destruction of the cellular structure occurs, lies in the range of 5.5 ... 6.0%. An increase in the moisture content of the kernel in comparison with the indicated one worsens the quality of grinding (grinding).

The core, getting into the passages between the grinding rolls of the roller mill, is crushed due to the difference in the circumferential speeds of the rolls, the presence of corrugations on their surfaces, as well as the different size of the gap between the rolls, i.e. turns into a mint.

Meat (passage through a 1 mm sieve at least 60%) with a moisture content of 5 ... 6% after roller machines by a screw conveyor 50 served for pressing.

Underperformance from the first sections of working seed plants 16 screw conveyor 21 , as well as undershooting from the first sections of the seed plant for undershooting 35 screw conveyor 36 served for control by elevator 23 , screw conveyor 24 in seedlings 25 where the husk is separated from it.

From seedlings 25 undershoot by screw conveyor 27 , noria 28 , screw conveyor 29 is fed for repeated caving on the centrifugal crumb of undersharpening 30 ... Part of the oil dust separated from the rushanka in a centrifugal rush is removed from it by a screw conveyor 33 into the screw conveyor core 22 where the oil dust is mixed with the core.

a) Fig. 2.11. Machine-hardware diagram of the line for the production of vegetable oil from sunflower seeds

Rushanka is fed by gravity into seed grain for undershortening 35 with a scraper conveyor 34 , the division in them into fractions occurs in the same way as in the working seed-grain 16 ... Core screw conveyors 22 , 48 fed into the core bins above the roller machines and then into the roller machines 49 ... Seedling undershortening 35 connects with undershoot from working seedlings 16 and with the help of the bucket elevator 23 and screw conveyor 24 goes to the control in seed lines 25 for separation of husk. Transfer from seedlings 35 connects with a rewe of working seedlings 16 and screw conveyor 19 , noria 38 , screw conveyor 39 served in seed grain 40 for the control of rewintering in order to separate the husk. The core from it enters the screw conveyor of the core 22 over roller machines.

b) Fig. 2.11. (Continuation)

Husk with oil content not more than 0.8% higher than botanical from working seed crops 16 25 and rewind 40 , seedlings for under-shedding 35 screw conveyor 20 , noria 42 , screw conveyor 43 goes to sieves to control husk 44 where the oilseed dust is separated from the husk. Husk by screw conveyor 45 the husk is fed into the pneumatic transport and removed from production.

Oil Dust from Sieves 44 screw conveyor 46 is fed for mixing with mint into a screw conveyor 50 .

Aspiration of worker seeds 10 and 30 carried out by fans 12 and 32 ... Oil dust settles in cyclones 11 and 31 and then a screw conveyor 13 fed into the screw conveyor 50 .

16 precipitates in cyclones 17 and is fed by a screw conveyor 18 also in the screw conveyor 50 .

Oil dust from aspiration of worker seed 16 , seedlings to control undershortening 25 and rewind 40 and seedlings for under-sap 35 precipitates in cyclones 17 , 26 , 41 , 37 and is fed by the screw conveyor 18 for mixing with oil also into the screw conveyor of oil 50 .

Obtaining press oil on the line is carried out as follows. Meat enters the auger inactivator 51 where it is intensively heated with live steam to a temperature of 80 ... 85 ° C and moistened with a mixture of water vapor and condensate up to 8 ... 9% through nozzles directly into the flow of oil. The ointment moved by auger rolls through the outlet pipe enters the upper vat of the brazier 52 .

With the help of knife mixers, the material is gradually mixed and moved from vat to vat, undergoing additional moisture-heat treatment. The moisture content of the mint is brought to 7 ... 9%, the temperature is up to 100 ... 105 ° С. The evaporated moisture is removed from the vats through a vertical collector using a fan. The pulp prepared in the braziers is fed by the feeder to the squeezing presses (forpress) 53 where the oil is pre-squeezed. The squeezed oil containing solid particles of the pressed material, which are carried out by the flow through the grain slots, enters the bed of the bed and then by the oil-collecting auger 64 and noria 65 goes for cleaning.

For primary cleaning, forepress oil enters the vibration classifier 66 , from where the previously cleaned from large suspended particles is sent to the oil sump 67 and then pump 68 through the discharge manifold 69 fed to the filter 70 ... The first, still cloudy, portions of filtered oil and the oil remaining in the filtrate after cleaning its filter surfaces are sent to the container 74 from where by pump 73 re-fed to the discharge manifold 69 .

When unrefined press oil is produced, the product from the filter 70 served for cooling and subsequent filling. To get refined oil from the filter 70 the product is sent to hydration.

Filtered sediment and sediment from the vibroclassifier are fed to the storage-dispenser 71 from which it is continuously and evenly pumped by a pump 72 into an extractor or roasting pan 61 .

The processing technology of the forepress cake depends on the type of oil produced. If the line is intended for the release of press oil, then the prepress cake with reduced content oil, after coarse grinding by cutters installed on the shaft of the squeezer, is directed by a screw conveyor 54 and noria 55 for further grinding. The thickness of the cake shell should be 7 ... 8 mm, the oil content of the cake should not exceed 18%.

The cake is crushed on disc 56 and roller 57 mills. The crushed prepress cake in terms of the degree of grinding should be homogeneous with a passage through a 1 mm sieve of at least 80%.

Shredded prepress cake by a screw conveyor 58 , noria 59 and distribution auger conveyor 60 is fed to final pressing oil extractors. They include braziers 61 and squeeze presses 62 ... Oil from the presses 62 goes to the oil collecting screw conveyor 64 for primary cleaning.

The thickness of the cake shell coming out of the press should be 5 ... 7 mm, the oil content of the cake should not exceed 7%. From the press 62 cake by screw conveyor 63 served in the warehouse.

The machine-hardware diagram of the equipment complexes for obtaining the extraction refined oil, which are part of the line, is shown in Fig. 2.11, b.

Forpress cake by an elevator 75 and screw conveyor 76 fed to hammer mill 77 ... The resulting grit is transported by a screw conveyor to a flattening roller machine 78 and comes out of it in the form of petals. The thickness of the petal is 0.3 ... 0.4 mm, the passage through the 1 mm sieve is not more than 4%, the moisture content is 8 ... 9%. Prepared cake in the form of petals by a scraper conveyor 79 goes to the loading column of the extractor 80 .

In the extractor 80 the cake is defatted with a solvent (gasoline) entering the extraction column. Extraction is carried out according to the counter-current principle, i.e. pure solvent, heated to 55 ... 65 ° C, goes to the most fat-free material, and concentrated miscella - to freshly loaded raw materials. The ratio of the material to be extracted and the solvent is 1.0: 1.1.

After passing through the extraction column, the solvent descends from top to bottom, passes into the horizontal screw and enters the lower part of the loading column. Rising upward, the solvent (gasoline) becomes more and more saturated with oil and forms a miscella, which comes out of the extractor. The concentration of miscella is 20 ... 25% oil.

Extractor miscella 80 drains into a collection of unfiltered miscella 81 from where by pump 82 fed to the disc filter 83 ... The pressure on the filter is not higher than 0.2 MPa, the temperature is 50 ... 60 ° C, the content of mechanical impurities before the filter is 0.4%, after the filter is not more than 0.02%. From it, the miscella enters the collection of filtered miscella. 84 .

The sludge from the filter (sludge) is returned to the bottom of the extractor loading column.

Distillation is carried out in three stages:

Stage I at a temperature of 60 ... 85 ° C and atmospheric pressure brings the concentration of oil in the miscella to 55 ... 60%;

Stage II at 90 ... 100 ° C and atmospheric pressure, the concentration of oil in the miscella is up to 90 ... 95%;

Stage III at 95 ... 110 ° C and rarefaction (vacuum) 0.04 ... 0.06 MPa, oil is obtained without solvent.

Filtered miscella from the collection 84 pumped through the heater 85 to the preliminary distiller of the 1st stage 86 ... Partially stripped off miscella pump 87 fed to the II stage of distillation 88 , from where the highly concentrated miscella is pumped through the preheater to the III stage of distillation into the distiller 89 for the final distillation of the solvent. All three distillers are heated by steam jackets, in the distiller 89 hot steam is also served.

Extraction oil obtained from the still 89 is continuously pumped out by a pump through the refrigerator, cooled to 50 ... 60 ° С and enters the collection 90 ... From it oil by pump 91 served for hydrogenation.

Degreased material (meal) containing no more than 0.8 ... 1.2% oil, passing through the loading column, the horizontal auger and the extraction column is unloaded from the extractor 80 through the hole in the top of the column into the vat of the evaporator (toaster) 92 ... The by-pass of the meal from the vat to the vat occurs automatically using bypass valves. In each vat, the meal is heated and steamed to efficiently remove the solvent. From the bottom of the toaster 92 the meal, finally cleared of the solvent, is sent to the elevator (warehouse).

Solvent (gasoline) from the recycled solvent reservoir 100 fed to the extractor 80 pump through a water trap 101 and heater 102 ... Solvent vapors from the extractor 80 enter the condenser 103 ... Solvent vapors from distillers 86 , 88 , 89 go respectively to the capacitors 104 , 105 , 106 .

Vapors of solvent and water mixed with meal dust from the tank evaporator 92 enter a wet meal trap 93 where they are cleaned with hot water sprayed through nozzles. Purified vapors enter the condenser 94 ... Wash water and sludge from the wet meal trap are directed to the waste water evaporator 95 for distilling off the solvent from them, the vapors of which enter the condenser 96 .

Fuel-water condensate from condensers 103 , 104 , 105 , 106 , 94 , 96 , 107 after passing the condensate cooler 97 , enters the water separator 98 where the separation of gasoline and water takes place. Gasoline is drained into a working tank 99 and further into the tank of recycled solvent 100 ... The water is discharged into a gasoline-powered device and further into the sewer.

The recovery of solvent vapors from the vapor-air mixture is carried out in an oil absorption unit. Air-steam mixture from condensers 103 , 104 , 105 , 106 , 94 , 96 enters the condenser 107 and further into the absorber 108 ... To the top of the absorber 108 pump 111 dispensed from the collection 110 mineral oil pre-cooled in a cooler 109 ... Air-vapor mixture rising up in the absorber 108 , is irrigated with flowing mineral oil, saturating it with a solvent. The air purified from the solvent is discharged into the atmosphere through the flame arrester. Deboned mineral oil (saturated with solvent) from the absorber 108 pump 116 preheated in heat exchangers 114 and 115 , served in the desorber 112 where intensive stripping of the solvent from the mineral oil takes place. Skimmed mineral oil (solvent free) from the stripper 112 pump 113 through the heat exchanger 115 returns to the collection 110 .

Refining of sunflower oil on the described line is carried out as follows. Crude pressed and refined oil is fed to the hydrator 118 , simultaneously from the collection 117 hot water flows into the hydrator. For hydration, vegetable oil is treated with a small amount of softened water (condensate). The amount of condensate for hydration is determined for a homogeneous batch of oil under laboratory conditions by trial hydration.

The hydrator is equipped with a jacket required to maintain the optimum oil temperature of 45 ... 50 ° C. In the hydrator, with slow rotation of the mixer, coagulation and formation of moistened phosphatide flocks occurs. After filling the hydrator and the formation of well-formed flakes of phosphatides, stop the mixer and settle the oil for 1 ... 2 hours. The settled oil is pumped out through a hinged pipe into a collector for hydrated oil 122 ... From the collector, the oil can be pumped into the vacuum dryer 123 for drying or for alkaline refining in a neutralizer 125 .

Hydration sludge from the hydrator 118 enters the collection 119 from where by pump 120 fed into a horizontal rotary film apparatus 121 for drying to obtain a phosphatide concentrate.

In a vacuum dryer 123 dehydration of fats occurs under vacuum. The device maintains a residual pressure of 20 ... 40 mm Hg. Art. using a steam jet vacuum pump. Moisture contained in the oil entering the zone reduced pressure, intensively evaporates and is sucked off in the form of steam by a steam jet vacuum pump. The oil temperature in the apparatus is 85 ... 90 ° С. Dried hydrated oil is sent for shipment to the consumer. Oil with increased content moisture pump 124 returned to the machine 123 .

Hydrated oil from the collection 122 , directed to alkaline refining, is pumped into the neutralizer 125 where free fatty acids are removed from the oil. The oil in the apparatus is heated with a steam jacket to a temperature of 45 ... 50 ° C with stirring with a stirrer. An alkali solution is fed into the apparatus from the collection 126 and water-salt solution from the collection 127 and further mixing takes place for 20 ... 30 minutes. Then the oil temperature is increased to 55 ... 60 ° C, stirring is continued until well-settling soap stock flakes are formed, which is separated by settling. Duration of settling is up to 6 hours. The soap films formed as a result of neutralization of free fatty acids, precipitating, fall into a water-salt solution, the soap dissolves, and the entrained neutral fat is released. Soap stock with 35% fat is discharged into a special tank. The residual content of soap in the oil is not more than 0.01%. Oil from the apparatus goes for washing, drying and bleaching to the vacuum washing bleaching apparatus 128 ... Flushing in the apparatus is carried out with hot condensate. Washing is carried out at atmospheric pressure and a temperature of 75 ... 85 ° C until the soap is completely removed. Each flushing consumes 8 ... 10% of water by weight of the oil. After washing, the oil is dried by turning on the stirrer and creating a vacuum in the apparatus. Drying is carried out at a temperature not exceeding 95 ° C and a residual pressure of 110 ... 160 mm Hg. Art. Compliance with the drying regime guarantees a residual moisture content of about 0.2%.

At the end of drying, shut off the valve on the vacuum line, stop the vacuum pump, eliminate the vacuum and, without stopping stirring, pump the oil for filtration into the filter press 129 ... The water-fat emulsion is discharged into a grease trap.

Refined filter press oil 129 enters the collection of refined oil 130 from where it is pumped to the deodorizer 131 ... It creates a vacuum with a steam jet vacuum pump. Refined oil is heated in a deodorizer to 100 ° C, after which, without stopping further heating, the required amount of hot (overheated) steam (up to 250 kg / h) is supplied to the oil through a bubbler, having a temperature of 325 ... 375 ° C. The rise in oil temperature to 180 ° C should last no more than 30 minutes. With periodic deodorization, the process temperature is not lower than 210 ° C. The residual pressure in the apparatus when operating with an ejection unit should be no more than 0.66 kPa.

To improve the quality, citric acid is injected directly into the oil in the deodorizer in the form of a 30% solution. Duration of deodorization is on average from 1.5 to 3 hours. Oil quality control is carried out organoleptically. If the deodorant is tasteless and odorless, the deodorization is stopped. At the end of deodorization, the oil is cooled in a deodorizer to 100 ° C, after which the deodorized oil enters the cooler 132 , in which a vacuum is preliminarily created, where the oil is cooled to 25 ... 30 ° C. This will form and remove wax crystals. The cooled deodorized oil is pumped to the filter press for filtration. 133 from where it goes to the collection 134 .

Finished oil after weighing on scales 135 served in the car 136 for filling into bottles, which are then packed into shipping containers in a machine 137 .

Do you know that Russia is one of the world leaders not only in oil production, but also in the production of sunflower oil? I also learned about this with surprise. To find out how a product so necessary in cooking is obtained from seeds, I went to Voronezh, to one of the largest factories in Russia for the production of sunflower oil.

Today in a special report for a story about how sunflower gold is squeezed out of sunflower seeds.

Before the main story, we will learn about the history of the emergence of sunflower oil.

According to Wikipedia, the evolution of sunflower as a cultivated plant took place in the Russian Empire, and industrial production is associated with the name of Daniil Bokarev. In 1829, he invented a method for producing oil from sunflower seeds. Four years later, in 1833, in the Alekseevka settlement, Voronezh province (now the Belgorod region), merchant Papushin, with the assistance of Bokarev, built the first oil mill in Russia. In 1834 Bokarev opened his own oil mill. In 1835, the export of butter abroad began. By 1860, there were about 160 oil mills in Alekseevka.

Plants for the production of sunflower oil are built in the immediate vicinity of the place where sunflower seeds grow, that is, mainly in black earth or in the southern regions of Russia. This is done not only to make it convenient to transport seeds to the plant, but also for economic reasons - sunflower seeds weigh very little compared to the final product, and it is impractical to transport them over long distances.

The plant, which produces the famous in Russia brand of sunflower oil "Oleina", was built not so long ago, in 2008. However, within a short period of time, the company has taken a leading position among sunflower oil producers.

1

And we will probably go to production and find out how sunflower oil is made after all.

It all starts here. There is such a house with a shed in front of the entrance to the factory. This is the laboratory where the seed truck pulls up. Here, the quality of the incoming seeds to the plant is determined (weediness, moisture, oil content, pest infestation, etc.) If the seeds do not meet the requirements, then they are taken back to the producer. Dozens of these trucks with trailers stand in front of the entrance to the plant.

2

Then the seed truck is weighed.

3

Then you need to unload the seeds. It happens as follows - the truck drives into a special lift, where it is fixed with chains, then it rises at an angle, and the seeds are unloaded into a special container. From there, they are sent along transport belts to be cleaned from litter and, if necessary, to a dryer for drying. And already the seeds can be transferred to storage in silos (storage).

4

The huge cylindrical containers in the photo are the very storages. Here the seeds are kept at a specific temperature. The higher the oil content of the seeds, the greater the oil yield.

5

There are many different containers on the territory of the plant. Some are for storing seeds, others - for storing processed raw materials - cake, meal. I will tell you what it is next.

6

By the way, the meal looks like this.

7

Move on. Traffic on the territory of the plant is organized stricter than in traffic rules: there are prohibitory signs everywhere, and pedestrians are allowed to walk through the territory of the plant only in a dedicated lane.

8

The plant has its own railway line. From here the processed raw materials (oil, meal) go to various regions.

9

But back to production. Seeds ready for processing are transported via transport belts to the first stage of production.

10

In the workshop for processing seeds, the shelling (destruction of the skin) of the seeds takes place and its separation from the kernel

11

Collapse occurs in these devices. With the help of centrifugal force, the seeds are broken against the whips, resulting in a rushanka (kernel and husk). Then the kernels are separated from the husk and each part is sent in its own way for further processing.

12

13

The kernel is sent for moisture-heat treatment in a brazier, where it is heated up to 90C and is prepared for oil extraction in presses. At this stage, press oil is obtained, which, after filtration, is sent for temporary storage, and the resulting solid and oilseed cake is transferred to the next stage.

15

The characteristic taste of the oil after hot pressing is reminiscent of toasted sunflower seeds. Oils obtained by hot pressing are more intensely colored and aromatized due to oxidation products that form during heating. And cold-pressed sunflower oil is obtained from mint without heating. The advantage of such oil is the preservation of most of the nutrients in it: antioxidants, vitamins, lecithin. The negative point is that such a product cannot be stored for a long time, it quickly becomes cloudy, rancid and becomes hazardous to health.

The cake, which remains after the oil is pressed, is transferred to extraction for a deeper extraction of the oil. or used in animal husbandry. Sunflower oil obtained by the pressing method is called press oil, since after pressing it is only defended and filtered. This product has high taste and nutritional properties.

In the photo I am holding a piece of cake.

16

Hipsters are not allowed!

17

In this building there are devices for the refining (purification) of oil from accompanying organic impurities. Refined oil has practically no color, taste or smell. The cleaning process consists of several stages.

18

At the first stage, phosphatides are removed or hydrated - treated with a small amount of hot water - up to 70 ° C. As a result, phospholipids become insoluble in oil and precipitate, after which they are separated in centrifugal separators. , Phospholipids are useful substances, but not stable in oil. During storage, they form a sediment in the oil and the oil begins to turn rancid, and when frying in a pan, they burn.

Refined oil has a slightly lower biological value than crude oil, since part of the phosphatides is removed during hydration, but it is stored longer. Such processing makes the vegetable oil transparent, after which it is called marketable hydrated.

In the second stage, the oil is bleached. Bleaching - treatment of oil with adsorbents of natural origin (most often special clays) that absorb coloring components, after which the oil is clarified. Pigments pass into oil from seeds and also threaten with oxidation of the finished product. After bleaching, the oil becomes light yellow in color.

Tools for the maintenance of oil filtration apparatus.

20

After bleaching, the oil is sent to the freezing section. Freezing is the removal of wax from the oil. All seeds are covered with wax, this is a kind of protection from natural factors. The wax gives the oil turbidity and thus spoils its presentation. The cleaning process in this case occurs when the oil is cooled to a temperature of 8-10 C and the addition of cellulose (of natural origin), after keeping the oil at this temperature and subsequent filtration, the oil is transparent.

Deodorization - removal of free fatty acids and aromatic substances by exposing sunflower oil to hot, live steam at high temperatures in a deep vacuum. During this process, odoriferous substances and free fatty acids, which characterize the quality of the oil, are removed. In addition, deodorization removes odorizing substances that give the oil taste and smell, as well as pesticides.

Removal of the above, undesirable impurities leads to the possibility of increasing the shelf life of the oil. After going through all the stages, the vegetable oil becomes impersonal - without color, taste, smell. Margarine, mayonnaise, cooking fats are made from such a product, used for canning, as well as for frying.

21

After all the circles of cleaning hell, the oil gets into these huge containers. Sorry to use the word "huge" again, but the scale of production is such that everything is huge here).

22

Oil will be delivered to individual customers in a tank car.

23

We learned about the process of oil production and its purification, now we will go to the final stage - to the bottling workshop.

Seeing this slogan, another field of human activity came to my mind, which I will not voice now. What associations do you have?

25

But before visiting the workshop, you must put on dressing gowns, a hat, shoe covers and wash your hands. In almost all food industries, such rules.

26

Remember these rules.

27

The bottles into which the oil will be poured are made like all plastic bottles from such preforms. For bottles of different containers, the preforms are different.

28

They are loaded into this container, it moves the preforms to the blow molding machine, which blows the bottle out of it at the right temperature.

29

It goes like this:

30

31

Here is such a simple magic.

32