Normalization of noise in the workplace. Noise regulation in residential and public premises. Permissible noise level Application and general provisions

Prevention of the harmful effect of noise on the human body begins with its regulation. Noise regulation consists in establishing safe sound levels, the excess of which is a threat to the life and health of the population, as it creates the risk of developing diseases associated with the adverse effect of noise.

Normalized by the following indicators:

- sound level (for constant noise);

- equivalent sound level (this indicator equates the sound level of inconsistent noise over a certain period of time to a certain sound level of constant broadband noise);

- maximum sound level (for intermittent noise);

- sound pressure levels in octave bands with geometric mean frequencies of 31.5 Hz, 63 Hz, 125 Hz, 250 Hz, 500 Hz, 1000 Hz, 2000 Hz, 4000 Hz, 8000 Hz.

The principles of noise rationing in residential and public buildings and workplaces differ from each other.

Noise regulation in residential and public buildings and in the adjacent territory

For residential premises and premises in public buildings and institutions, permissible noise levels have been established.

Acceptable level noise is a level that does not cause significant anxiety in a person and significant changes in indicators functional state systems and analyzers sensitive to noise.

In other words, such noise is not only invisible to humans, but also will not cause absolutely any physiological effects on the part of the body. To such a noise the human body you do not have to adapt, which means that it is not a stress factor.

Let me remind you that the criterion for the "noticeability" of noise, i.e. its subjective perception, by itself cannot determine any norms of noise, since a person gets used to the subjective perception of even sufficiently high noise levels, but getting used to noise in the physiological sense does not occur. Fatigue and physiological effects caused by noise accumulate over time and can result in various functional disorders and diseases, which is why the ability of noise at certain levels to cause the appearance of such effects determines the norms of noise along with its subjective perception.

If the permissible noise level is not exceeded, then it does not bother people in such an environment, it creates a comfortable atmosphere for doing everyday activities, does not cause fatigue, and contributes to active or calm rest.

When normalizing noise, various states of a person are also taken into account, both physiological and caused by various diseases, for example, noise that is invisible to a waking person, especially if he is having fun or is engaged in active rest, will interfere with a person who is trying to fall asleep, which means interfere with the normal course of sleep and rest of the body, which is fraught with its health. Therefore, for premises in which people can be around the clock, various standards have been established for the daytime (from 7 to 23 hours) and for the night time (from 23 hours to 7 hours).

Likewise, noise that does not interfere healthy person, can cause discomfort for a sick person. Therefore, for residential premises, and for premises equated to them, the noise standards are slightly higher than for chambers of hospitals and sanatoriums.

In classrooms, the permissible noise levels are commensurate with the norms for living quarters, since in order to focus on the educational process, any distractions are completely unnecessary.

For public institutions in which people have fun, make purchases, receive any services, noise levels are higher than for residential buildings, educational and medical institutions.

Permissible noise levels have been established for public areas.

Where are noise standards for residential and public spaces established?

The permissible noise levels are established in special regulatory documents that regulate the criteria for safety and harmlessness to human health of various environmental factors and requirements that provide favorable conditions for human life. Such documents are: sanitary rules (SP), sanitary and epidemiological rules and regulations (SanPiN), sanitary standards (SN).

All of the listed types of documents are mandatory for the fulfillment of their requirements by citizens, individual entrepreneurs, legal entities, regardless of their affiliation and type of ownership.

Failure to comply with the mandatory requirements of the above regulatory documents provides for civil, administrative and criminal liability.

The main document establishing permissible noise levels is SN 2.2.4 / 2.1.8.562-96 "Noise at workplaces, in residential, public buildings and on the territory of residential development."

In addition to it, noise standards are regulated in specialized SP and SanPiN, for example, SanPiN 2.1.2.2645-10 "Sanitary and epidemiological requirements for living conditions in residential buildings and premises", SP 2.1.2.2844-11 "Sanitary and epidemiological requirements for a device, equipment and maintenance of hostels for employees of organizations and students educational institutions" etc.

Noise concept

Noise - these are random vibrations of various physical nature, characterized by the complexity of the temporal and spectral structure. From a physiological point of view, noise is any perceived unfavorable sound.

Sound - these are elastic waves that propagate longitudinally in the medium and create mechanical vibrations in it; in a narrow sense - the subjective perception of these vibrations by special human senses.

The effect of the factor on the human body

Prolonged exposure to noise can impair hearing, and in some cases, deafness. Noise exposure in the workplace adversely affects workers and leads to:

- slowing down the speed of mental reactions, etc.

decreased attention;

an increase in energy consumption with the same physical activity;

Sound is generally associated with the auditory sensations of a person with normal hearing. Hearing sensations are caused by vibrations of an elastic medium, which are mechanical vibrations that propagate in a gaseous, liquid or solid medium and affect the human hearing organs. At the same time, vibrations of the environment are perceived as sound only in a certain frequency range (20 Hz - 20 kHz) and at sound pressures exceeding the human hearing threshold.

As a result, labor productivity and the quality of the work performed are reduced.

Figure 1 shows the structure of the hearing organ.

Figure 1 - The structure of the organ of hearing

Primary sound analysis takes place in the cochlea. Each simple sound has its own section on the basilar membrane. Low sounds cause vibrations of parts of the basilar membrane at the apex of the cochlea, and high sounds at the base of it.

The wave moves from the stirrup to the top of the snail. When the amplitude reaches its maximum, the wave decays quickly. In this area, eddy currents of the perilymph arise, and the maximum deflection of the basilar membrane occurs. Low frequency sounds will travel through the entire cochlea and cause maximum deflection at the apex. High frequency sounds will only vibrate the basilar membrane at the base of the cochlea. The nervous excitement arising in the auditory receptor by auditory nerve transmitted to the auditory cortex, where a sound image is formed. Figure 2 shows the mechanism for the formation of audible sounds.

Figure 2 - The mechanism of formation of audible sounds

Perceptual areas of sound intensity levels

- III area - covers levels from 80 - 90 dB to the threshold of unpleasant sensation - 120 - 130 dB. In this area, the functions of the auditory analyzer differ significantly depending on the frequency, intensity and time of sound exposure.

I area - includes a range of levels from the hearing threshold to 40 dB and covers a limited number of signals, as a result of which a person does not have daily training to perceive such sounds; the ability to differentiate sounds is limited.

II area - includes levels from 40 to 80 - 90 dB and covers the bulk of useful signals, this area contains the levels of speech intensity from whispering to the loudest radio broadcast, musical sounds, etc. Here the ability to subtly differentiate and analyze the quality of sound (both in frequency and intensity) is noted. A person is most adapted to the perception of sounds in this area.

Factor classification

The classification of the "Noise" factor is shown in Table 1.

Table 1

| Classification method | Noise type | Noise characteristic |

|---|---|---|

| By the nature of the noise spectrum | Tonal | The noise spectrum has pronounced discrete tones |

| Broadband | Continuous spectrum more than one octave wide | |

| By time characteristics | Permanent | Sound level for an 8-hour working day changes by no more than 5 dB (A) |

| Fickle: | ||

| Fluctuating in time | The sound level changes by more than 5 dB (A) over an 8-hour workday. Sound level continuously changes over time | |

| Intermittent | The sound level changes stepwise by no more than 5 dB (A), the duration of the interval is 1 s or more | |

| Pulse | Consist of one or more sound signals, the interval duration is less than 1 s |

Normalized indicators of factors

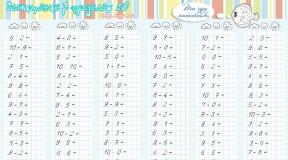

Normalized indicators for constant and intermittent noise are given in Table 2.

table 2

Standards

The maximum permissible noise levels at workplaces are established taking into account the severity and intensity of work. To determine the remote control for the noise corresponding to a particular workplace, it is necessary to quantify the severity and intensity of the work performed by the employee. The maximum permissible sound levels and equivalent sound levels at workplaces for work activities of different categories of severity and intensity in dBA are presented in Table 3.

Table 3. Maximum permissible sound levels and equivalent sound levels at workplaces for work activities of different categories of severity and intensity in dBA

The maximum permissible sound pressure levels, sound levels and equivalent sound levels for the main most typical jobs and workplaces are presented in Table 4.

| Labor activity, workplace | Sound levels and equivalent sound levels in dBA |

| Creative activity, management work with increased requirements, scientific activity, design and engineering, programming, teaching and learning, medical practice. Workplaces in the premises of the directorate, design bureaus, calculators, computer programmers, in laboratories for theoretical work and data processing, receiving patients in health centers | 50 |

| Highly skilled work requiring concentration, administrative and managerial activities, measuring and analytical work in the laboratory; workplaces in the premises of the shop management apparatus, in the working rooms of the office premises, in the laboratories | 60 |

| Work performed with frequently received directions and acoustic signals; work that requires constant auditory monitoring; camera work on a precise schedule with instructions; dispatching work. Workplaces in the rooms of the dispatch service, offices and rooms for observation and remote control with voice communication by phone; typewriting bureaus, precision assembly areas, telephone and telegraph stations, craftsmen's premises, information processing rooms on computers | 65 |

| Work that requires concentration; work with increased requirements for monitoring processes and remote control of production cycles. Workstations behind consoles in observation and remote control cabins without voice communication by telephone, in rooms for accommodating noisy computer aggregates | 75 |

| Performing all types of work (with the exception of those listed in clauses 1-4 and similar) at permanent workplaces in production facilities and on the territory of enterprises | 80 |

| Workplaces in the cabins of locomotives, electric locomotives, subway trains, diesel trains and railcars | 80 |

| Workstations in the cabins of drivers of high-speed and suburban electric trains | 75 |

| Premises for personnel of long-distance train carriages, office premises, refrigerated sections, power station cars, luggage and post offices rest rooms | 60 |

| Service rooms in baggage and mail cars, restaurant cars | 70 |

| Workplaces for drivers and service personnel of trucks | 70 |

| Workplaces for drivers and service personnel (passengers) of cars and buses | 60 |

| Workplaces for drivers and maintenance personnel of tractors, self-propelled chassis, trailed and mounted agricultural machines, road-building and other similar machines | 80 |

Table 4. Maximum allowable sound pressure levels, sound levels and equivalent sound levels for the main most typical jobs and workplaces

Classes of working conditions depending on the noise levels are presented in table 5

Table 5. Classes of working conditions depending on the noise levels at the workplace

Measurement technique

When measurements are taken at some reference time intervals, they are chosen to cover all typical and repetitive day-to-day noise situations [it is important to identify any significant noise changes in the workplace, eg 5 dB (dBA) or more]. In this case, the measurement results obtained in different shifts will not be contradictory.

Duration of measurements within each reference time interval

- for intermittent noise, the reasons for the fluctuations of which cannot be clearly associated with the nature of the work performed - 30 minutes (three measurement cycles of 10 minutes each) or less, if the measurement results for a shorter duration do not diverge by more than 0.5 dB (dBA);

for constant noise not less than 15 s;

for non-constant, including intermittent, noise, it should be equal to the duration of at least one repetitive operating cycle or a multiple of several operating cycles. The duration of measurements can also be equal to the duration of some characteristic type of work or part of it. The duration of measurements is considered sufficient if, with its further increase, the equivalent sound level does not change by more than 0.5 dBA;

for impulse noise - not less than the transit time of 10 impulses (recommended 15 - 30 s)

Noise measurements to control the compliance of actual noise levels at workplaces with permissible levels according to current standards should be carried out when at least 2/3 of the units of installed equipment usually used in a given room are operating in the most frequently implemented (typical) mode of its operation or in another way, when a typical noise impact from noise sources not located in the workplace (in the working area). If it is known that equipment located far from the workplace creates background noise 15 - 20 dB lower than the noise during operation of the equipment installed at the workplace, then it should not be turned on.

Measurements should not be carried out during the conversations of workers, as well as when giving various sound signals (warning, information, telephone calls, etc.) and when the loudspeaker is working.

Measurements can be carried out in the presence or absence (the latter is preferable) of the operator (working) at the workplace or in the working area. Measurements are carried out at fixed points or with a microphone attached to the operator and moving with him, which provides a higher accuracy in determining the noise level and is preferred.

Fixed point measurements are made if the position of the operator's head is known exactly. In the absence of an operator, the microphone is installed at a predetermined measurement point located at the level of his head. If the position of the operator's head is not known exactly and measurements are carried out in the absence of the operator, then the microphone is installed for a seated workplace at a height of (0.91 ± 0.05) m above the center of the seat surface with its average adjustment position for the height of the operator, and for a standing worker places - at a height of (1.550 ± 0.075) m above the support on the vertical passing through the center of the head of an erect person.

If the presence of the operator is necessary, the microphone is positioned approximately 0.1 m from the ear that perceives the higher (equivalent) sound level, and oriented in the direction of the operator's gaze, if possible, or according to the manufacturer's instructions. If the microphone is attached to the operator, then it is installed on a helmet or shoulder using a frame, as well as on a collar at a distance of 0.1 - 0.3 m from the ear, but so as not to interfere with the operator's work and not create danger to him.

The microphone should be at least 0.5 m away from the operator taking measurements.

In the vicinity of a noise source, even small changes in the position of the microphone can significantly affect the measurement results. If tones are clearly visible at the measurement point, standing waves may occur. It is recommended to move the microphone several times in the range of 0.1 - 0.5 m and take the average value as the measurement result.

When the microphone is placed close to the operator, there can be a noticeable difference between measurements with and without an operator (usually the measurement results with an operator are higher). This is especially true when measuring high-frequency tonal noise or noise from small sources at close range. To prevent gross errors, it is recommended to compare the measurement results in the presence of an operator and without him and, if there are significant differences, calculate the average value.

Octave sound pressure levels, sound levels are measured with sound level meters of the 1st or 2nd class of accuracy.

The equipment is calibrated before and after the noise measurement in accordance with the instrument operating instructions.

Figure 3 shows the means for measuring the sound pressure level.

Figure 3 - Means for measuring the sound pressure level

Actual sound pressure levels

Examples of actual sound pressure levels are shown in Figure 4.

Figure 4 - Actual sound pressure levels

Measures to eliminate the harmful effects of noise

Measures to protect against noise of workplaces of industrial enterprises are primarily provided by the following construction-acoustic methods.

Acoustically rational solution to the general layout of the facility, rational architectural and planning solution of buildings

The main principle of protection is the grouping of premises with a high level of noise and their isolation from other parts of the building. As for the equipment of these premises, it is considered the most favorable installation in the center of the room. In this case, there will be only one reflective surface nearby - the floor. If the equipment is installed against a wall, it will also reflect sound waves and the noise will be amplified. This principle also applies to protection against structure-borne noise, with the only difference that the equipment must not touch the walls of the room.

Application of building envelopes with the required sound insulation

Building envelopes are walls, ceilings, partitions, etc. They are divided into external and internal. The external ones serve to protect against various climatic factors, and the internal enclosing structures - to divide and redevelop the internal space of the building.

It is recommended to design elements of fencing from materials with a dense structure that does not have through pores. Fences made of materials with through-porosity must have outer layers of dense material, concrete or mortar.

It is recommended to design internal walls and partitions made of bricks, ceramic and cinder-concrete blocks with filling of the joints to the full thickness (without gutting) and plastered on both sides with a non-shrinking mortar.

The enclosing structures must be designed so that during the construction and operation of their joints there is not and does not appear even minimal through gaps and cracks. The cracks and cracks arising during the construction process after their clearing must be eliminated by constructive measures and by sealing with non-drying sealants and other materials to the full depth.

Sound insulation of building structures is carried out by covering them with sound-absorbing materials. The effectiveness of soundproofing depends on the type of material used and on its thickness. The most effective are fibrous materials, which, due to their structure, transmit only a small percentage of noise. The thickness and material of the structures is determined based on acoustic calculations.

Application of sound absorbing structures

The presence of reflections of sound waves from the surfaces of a closed space (room) and objects in it usually increases the intensity of sound in comparison with the levels created by the same sound source radiating into free (open) space. To eliminate the reflected part of the sound field, various sound-absorbing materials and structures based on them are used.

Sound-absorbing structures (suspended ceilings, wall cladding, rocker and piece absorbers) should be used to reduce noise levels at workplaces and in areas where people constantly stay in industrial and public buildings.

Sound absorbing structures should be placed on the ceiling and on the tops of the walls. It is advisable to place the sound-absorbing structures in separate sections or strips. At frequencies below 250 Hz, the effectiveness of the sound-absorbing cladding increases when it is placed in the corners of the room.

The area of \u200b\u200bthe sound-absorbing linings and the number of piece absorbers are determined by calculation.

Piece absorbers should be used if the cladding is insufficient to obtain the required noise reduction, as well as instead of a sound-absorbing suspended ceiling, when its construction is impossible or ineffective (high height of the production room, the presence of bridge cranes, the presence of light and aeration lights). Sound-absorbing structures should be used as mandatory measures to reduce noise and ensure optimal acoustic parameters of premises: in noisy workshops of industrial enterprises; in computer rooms of computing centers; in soundproof cabins, boxes and shelters.

The acoustic properties of materials substantially depend on their structural parameters, which determine the field of application of these materials. So, if noise reduction is required in the low-frequency range, it is advisable to use linings made of ultra- or super-thin fibrous materials with a density of 15 - 20 kg / m3. To reduce broadband noise in the medium and high frequency range, materials with coarser fibers with a density of 20-30 kg / m3 or more should be selected.

It should be noted that in the area of \u200b\u200bdirect sound, sound-absorbing structures practically do not reduce noise levels.

Application of soundproof observation booths and remote control

Soundproof booths should be used in industrial workshops and in areas where permissible levels are exceeded to protect workers and maintenance personnel from noise. Soundproof booths should have control panels for “noisy” technological processes and equipment, workplaces for foremen and shop managers.

Depending on the required sound insulation, the cabins can be designed from conventional building materials (brick, reinforced concrete, etc.) or have a prefabricated structure assembled from prefabricated structures made of steel, aluminum, plastic, plywood and other sheet materials on a prefabricated or welded frame ...

Soundproofing cabins should be installed on rubber vibration isolators to prevent transmission of vibrations to the enclosing structures and the cab frame. The internal volume of the cabin must be at least 15 m3 per person. Cab height (inside) - not less than 2.5 m. The cab must be equipped with a ventilation or air conditioning system with the necessary silencers. The internal surfaces of the cabin should be 50 - 70% lined with sound-absorbing materials.

The cab doors must have sealing gaskets in the narthex and locking devices to ensure the compression of the gaskets. The cabins of the 1st and 2nd classes must have double doors with a vestibule.

Application of soundproof enclosures on noisy units

The use of soundproof enclosures is one of the most effective solutions to the problem of insulation of units with increased noise levels. It is advisable to use the soundproof casing in cases where the noise generated by the unit (machine) at the design point exceeds the permissible value by 5 dB or more in at least one octave band, and the noise of all other technological equipment is in the same octave band (at the same design point ) is 2 dB or more below the allowable value.

Soundproof enclosures are usually made of fibrous materials, and the frame is thin perforated metal panels. If the amount of sound insulation of airborne noise does not exceed 10 dB at medium and high frequencies, then the casing can be made of elastic materials (vinyl, rubber, etc.), if it exceeds, the casing should be made of sheet structural materials. The casing elements must be fixed to the frame.

The metal casing should be covered with vibration-damping material (sheet or in the form of mastic), while the thickness of the coating should be 2 - 3 times the wall thickness. On the inside, on the casing, a layer of sound-absorbing material with a thickness of 40 - 50 mm must be placed. To protect it from mechanical stress, dust and other contaminants, use a metal mesh with fiberglass or a thin film 20-30 microns thick.

The cover must not have direct contact with the unit and piping. Technological and ventilation openings must be equipped with mufflers and seals. The installation of soundproof enclosures is one of the main measures to reduce the noise of ventilation equipment in buildings and premises. They are installed on supply air, some exhaust units and air conditioners. Soundproof enclosures are two metal sheets with sound absorbing material between them. The acoustic efficiency of such enclosures can be up to 10-15 dB at low frequencies and up to 30-40 dB at high frequencies.

Application of acoustic screens

An acoustic screen is a kind of barrier between the workplace and the source of noise, with a high level of sound insulation. Screens should be used to reduce sound pressure levels at workplaces in the direct sound area and in the intermediate area. Install screens as close to the noise source as possible.

Screens should be made of solid sheet materials or separate shields with obligatory lining with sound-absorbing materials of the surface facing the noise source.

Structurally, screens can be flat and U-shaped (in this case, their efficiency increases). If the screen is surrounded by a noise source, then it turns into an enclosure and its efficiency approaches that of an infinite screen with a height h. It is advisable to use baffles for the source (s) of noise, the sound power levels of which are 15 dB or more higher than for other noise sources.

Screen elements can be positioned vertically and at a certain inclination to the horizontal (vertical) plane. The angle of inclination depends on the relative position of the noise source and the workplace.

The main parameters of the screen (height, shape, thickness of the sound-absorbing lining), at which the specified acoustic efficiency is ensured at a fixed distance to the noise source, are determined by calculation. The linear dimensions of the screens should be at least three times the linear dimensions of the noise source.

Reducing the noise of fans and the use of silencers in ventilation systems, air conditioning and in aerodynamic installations

To reduce fan noise, you should: select the unit with the lowest specific sound power levels; ensure that the fan operates at maximum efficiency; reduce the resistance of the network and do not use a fan that creates excessive pressure; ensure smooth air supply to the fan inlet.

To reduce the noise from the fan along the path of its propagation through the air ducts, it is necessary to: provide central (directly at the fan) and end (in the air duct in front of the air distribution devices) noise mufflers; limit the speed of air movement in networks to a value that ensures the levels of noise generated by regulating and air distribution devices within the permissible values \u200b\u200bin the manned premises.

Tubular, plate, duct, cylindrical, screen and chamber, as well as air ducts lined with sound-absorbing materials and their turns can be used as silencers of ventilation systems.

The design of the muffler should be selected depending on the size of the duct, the required reduction of noise levels, the permissible air speed based on the calculation according to the relevant set of rules.

Vibration isolation of technological equipment

Airborne noise, especially vibrations, propagating with low attenuation along the supporting and enclosing structures of buildings, as well as along pipelines and walls of canals and shafts in buildings, are emitted by them in the form of structural (shock) noise in rooms that are far from sources of noise and vibration. Structural noise protection is carried out by methods of acoustic vibration isolation of engineering equipment and its communications. These methods include the installation of flexible inserts and vibration dampers, equipment of the premises with floors on an elastic foundation (floating floors).

In the first case, to reduce the structure-borne noise of ventilation equipment, flexible linen canvas inserts are installed on the discharge and intake sides of the fans. The inserts are manufactured in accordance with standard drawings and have rectangular and circular cross-sections. For pumps and refrigeration machines, flexible rubber sleeves are used.

Another way is to reduce noise by using vibration dampers. To achieve the goal in practice, vibration isolators of two types are often used: steel spring and rubber vibration isolators.

Rubber vibration isolators, the maximum allowable static deflection of which is 30% of their height, are used at a speed of more than 1800 rpm. These vibration isolators effectively reduce the transmission of vibration at high frequencies. However, their use does not significantly reduce the transmission of vibration at low frequencies. In addition, rubber vibration isolators have low wear resistance. The most effective is the use of combined vibration isolators, consisting of spring vibration isolators, which are mounted on rubber or cork gaskets 10 - 20 mm thick and adjoin the supporting surface.

The third way is to use floors on an elastic foundation (floating floors). Their efficiency may be lower than that of vibration isolators (in the calculated frequency band), but the damping ability of such floors is manifested in a wide frequency range.

In structures of this type, as well as in sound insulation in general, it is necessary to strictly monitor the absence of through holes and slots in the insulating structures, tight junction of the elements to each other. In the case of "floating floors", elastic pads should go up the walls along their perimeter, avoiding rigid mechanical contact of the floor (screed) with the walls.

Organizational methods of noise protection should be noted (see below).

Selection of rational operating modes of equipment, limiting the time spent by personnel in the area of \u200b\u200boperation of units (machines) with an increased noise level (protection "time")

Protection "by time" provides for being in rooms with a high level of noise only on a business need with a clear regulation of the time of actions; work automation; reducing the time of adjustment work, etc.

The duration of additional regulated breaks is set taking into account the noise level, its spectrum and personal protective equipment. For those groups of workers where, according to safety regulations, the use of anti-noise (listening to signals, etc.) is not allowed, only the noise level and its spectrum are taken into account.

Rest during the regulated breaks should be carried out in specially equipped rooms. During the lunch break, those working under the influence of increased noise levels should also be in optimal acoustic conditions (with a sound level not exceeding 50 dBA).

Use of personal hearing protection

Hearing protection includes earplugs, ear muffs and helmets. The effectiveness of PPE can be ensured by their correct selection depending on the levels and spectrum of noise, as well as by monitoring the correct operation.

Lecture 9

Rationing and protection against industrial noise, infra- and ultrasound

1. Normalization of industrial noise 1

2.Methods of dealing with noise 2

3. Ultrasound. Rationing and protection 5

4. Infrasound. Rationing and protection 6

Test questions 6

1. Normalization of industrial noise

When normalizing noise, two methods are used: normalization according to the limiting noise spectrum and normalization of the sound level in dBA.

Limiting the spectrum. This method is basic for persistent noises. Here the sound pressure levels are normalized in 8 octave frequency bands with fsg \u003d 63, 125, 250 ... 8000 Hz. The set of eight permissible sound pressure levels is called the limiting spectrum (SS) - see Fig. 1.

For each category of workplaces (design offices, laboratories, workshops, etc.), its own maximum noise spectrum is regulated. Allowable sound pressure levels at workplaces are given in GOST 12.1.003-.

The figure shows that with increasing frequency, the permissible levels decrease. Each of the spectra has its own index, for example, PS-75, where “75” is the permissible sound pressure level in the octave band with a geometric mean frequency of 1000 Hz.

Normalization of the sound level in dBA. This method is used to roughly estimate constant and non-constant noise when we do not know the noise spectrum. The sound level is measured in decibels A (DBA) by a sound level meter operating in the frequency response mode A, which, as it were, "simulates" the sensitivity of the human auditory analyzer, which, as you know, has a maximum in the range of 3-5 kHz.

Sound level (dBA) is related to the limiting spectrum by the dependence

For tonal and impulse noise, the permissible levels should be taken 5 dB less than the standard for constant noise.

Figure: 2. Curve of sensitivity S of the auditory analyzer and characteristics of the sound level meter AND

To assess the acoustic energy acting on a person for a certain period of time, it is used dose of noise , corrected by the frequency characteristic "A" of the sound level meter Pa 2 hD = P A 2 T

where R AND is the sound pressure corresponding to the measured sound level in dBA.

Acceptable noise dose - the dose corresponding to the acceptable sound level or the acceptable equivalent sound level.

For non-constant noise, the normalized parameter is the equivalent (in energy) sound level of broadband, constant and non-pulse noise, which has the same effect on a person as non-constant noise (L a eq. DBA. This level is measured by special integrating sound level meters.

Noise control techniques

When designing new enterprises, industrial premises, it is necessary to take measures so that the noise in the premises does not exceed the permissible values. The development of measures to combat noise should be preceded by an acoustic calculation. Its tasks are:

Determination of the sound pressure level at the design point (PT), when the noise source and its noise characteristics are known;

Calculation of the required noise reduction.

The following methods are used to combat noise:

Reducing noise at the source (ie "protection by quantity")

The fight against noise at the source (by reducing the sound power level Lp) is most rational. Specific measures here depend on the nature of the noise (mechanical, aerohydrodynamic, electromagnetic). So the reduction of mechanical noise can be achieved by improving technological processes and equipment. To reduce aerohydrodynamic noise, one should strive to reduce the velocities of the flow around bodies (gas or liquid), to improve the aerodynamic qualities of the bodies in a stream. Reducing electromagnetic noise is achieved through design changes in electrical machines. For example, in transformers it is necessary to apply a denser compaction of packages, use damping materials.

When standardizing the permissible sound pressure at workplaces, the frequency spectrum of the noise is divided into nine frequency bands.

The normalized parameters of constant noise are:

- sound pressure level L,dB, in octave bands with geometric mean frequencies of 31.5; 63; 125; 250; 500; 1000; 2000; 4000; 8000 Hz;

- sound level bd, dB A.

The normalized parameters of intermittent noise are:

- equivalent (in energy) sound level Ld eq,dB A,

- maximum sound level bd max, dB A.

Exceeding at least one of these indicators is qualified as non-compliance with these sanitary standards.

In accordance with SanPiN 2.2.4 / 2.1.8.10-32-2002, the maximum permissible noise levels are standardized for two categories of noise standards: remote control for noise at workplaces and remote control for noise in residential, public buildings and on the territory of residential buildings.

Sound Remote Control and Equivalent Sound Levelsat workplaces, taking into account the tension and severity of labor activity are presented in table. 8.4.

Table 8.4 Maximum permissible sound levels and equivalent sound levels at workplaces

Remote control for sound pressure in octave frequency bands, sound levels and equivalent sound levels are presented in Appendix. 2 to SanPiN 2.2.4 / 2.1.8.10-32-2002.

211 For tonal and impulse noise, as well as noise generated in rooms by air conditioning, ventilation and air heating installations, the remote control should be taken 5 dB (dBA) less than the values \u200b\u200bindicated in Table. 8.4. of this paragraph and adj. 2 to SanPiN 2.2.4 / 2.1.8.10-32-2002.

The maximum sound level for oscillating and intermittent noise should not exceed 110 dB A. Even short-term exposure to areas with sound levels or sound pressure levels in any octave band above 135 dB A (dB) is prohibited.

Remote control for noise in residential, public buildings and residential areas.Permissible values \u200b\u200bof sound pressure levels in octave frequency bands of equivalent and maximum sound levels of penetrating noise into premises of residential and public buildings and noise on the territory of residential buildings are established in accordance with Appendix. 3 to SanPiN 2.2.4 / 2.1.8.10-32-2002.

Noise protection methods

The fight against noise in production is carried out in a comprehensive manner and includes measures of a technological, sanitary-technical, therapeutic and prophylactic nature.

The classification of means and methods of protection against noise is given in GOST 12.1.029-80 SSBT “Means and methods of protection against noise. Classification ", SNiP II-12-77" Protection against noise ", which provide protection against noise by the following construction-acoustic methods:

a) sound insulation of enclosing structures, sealing when

makers of windows, doors, gates, etc., by the device of soundproofed

bin for staff; by covering noise sources in enclosures;

b) installation in rooms in the path of noise propagation

sound-absorbing structures and screens;

c) the use of mufflers of aerodynamic noise in the engine

internal combustion devices and compressors; sound-absorbing about

face work in the air ducts of ventilation systems;

d) the creation of noise protection zones in various places where

people, using screens and green spaces.

Noise reduction is achieved by using elastic gaskets under the floor without their rigid connection with the supporting structures of buildings, installing equipment on shock absorbers or specially insulated foundations. Sound-absorbing means are widely used - mineral wool, felt boards, perforated cardboard, fiberboards, fiberglass, as well as active and reactive silencers (Fig. 8.3.).

Mufflersaerodynamic noise can be absorption, reactive (reflex) and combined. In absorption

G g g

Figure: 8.3. Silencers:

and- absorption tubular type; b-absorption

cellular type; g-absorption screen type;

d- reactive chamber type; e- resonant;

f- combined type; 1 - perforated tubes;

2 - sound absorbing material; 3 - fiberglass;

4 - expansion chamber; 5 - resonance chamber

in mufflers, noise attenuation occurs in the pores of the sound-absorbing material. The principle of operation of jet mufflers is based on the effect of sound reflection as a result of the formation of a "wave plug" in the muffler elements. Combined silencers both absorb and reflect sound.

Soundproofingis one of the most effective and common methods of reducing industrial noise along its path. With the help of soundproofing devices (Fig. 8.4), it is easy to reduce the noise level by 30 ... 40 dB. Effective sound insulating materials are metals, concrete, wood, dense plastics, etc.

|

| in | AND | |

| AND | B | |

| / r? Я7 ^^ - I / |

Figure: 8.4. Soundproofing device circuits:

and- soundproof partition; b- soundproof casing;

в - soundproofing screen; A - zone of increased noise;

B - protected area; 1 - noise sources;

2 - soundproof partition; 3 - soundproof casing;

4 - soundproof cladding; 5 - acoustic screen

To reduce noise in the room, sound-absorbing materials are applied to the internal surfaces, and piece sound absorbers are also placed in the room.

Sound-absorbing devices are porous, porous-fibrous, with a screen, membrane, layered, resonant and volumetric. The effectiveness of the use of various sound-absorbing devices is determined as a result of an acoustic calculation taking into account the requirements of SNiP II-12-77. To achieve the maximum effect, it is recommended to cover at least 60% of the total area of \u200b\u200bthe enclosing surfaces, and volumetric (piece) sound absorbers should be placed as close as possible to the noise source.

Reduce the adverse effect of noise on workers, possibly by reducing the time they spend in noisy workshops, rationally distributing the time of work and rest, etc. The working hours of adolescents in conditions of noise are regulated: for them it is necessary to arrange obligatory 10 ... 15-minute breaks, during which they must rest in specially designated rooms outside of noise exposure. Such breaks are arranged for adolescents who work the first year, every 50 minutes - 1 hour of work, the second year - after 1.5 hours, the third year - after 2 hours of work.

Areas with sound levels or equivalent sound levels above 80 dB A must be marked with safety signs.

Workers are protected from noise by collective means and methods and by individual means.

The main sources of vibration (mechanical) noise of machines and mechanisms are gears, bearings, colliding metal elements, etc. To reduce the noise of gears, you can improve the accuracy of their processing and assembly, replace the material of the gears, use bevel, helical and chevron gears. It is possible to reduce the noise of machine tools by using high-speed steel for a cutter, cutting fluids, replacing metal parts of machine tools with plastic ones, etc.

To reduce aerodynamic noise, special noise-damping elements with curved channels are used. Aerodynamic noise can be reduced by improving the aerodynamic characteristics of vehicles. Additionally, sound insulation and mufflers are used.

Acoustic treatment is mandatory in noisy machine-building shops, weaving factories, machine rooms of computer stations and computing centers.

A new method of noise reduction is anti-sound method(equal in magnitude and opposite in phase sound). As a result of the interference of the main sound and "anti-sound" in some places

a noisy room, you can create zones of silence. In the place where it is necessary to reduce the noise, a microphone is installed, the signal from which is amplified and emitted by the speakers located in a certain way. A complex of electroacoustic devices for interference noise suppression has already been developed.

Use of personal protective equipment against noiseit is advisable in cases where collective protective equipment and other means do not provide noise reduction to acceptable levels.

PPE can reduce the level of perceived sound by 0 ... 45 dB, and the most significant noise suppression is observed in the high frequencies, which are most dangerous for humans.

Personal protective equipment against noise is subdivided into ear muffs that cover the auricle from the outside; anti-noise earbuds that block the external ear canal or adjacent to it; anti-noise helmets and helmets; anti-noise suits. Anti-noise earbuds are made of hard, elastic and fibrous materials. They are single and reusable. Anti-noise helmets cover the entire head, they are used at very high noise levels in combination with headphones and anti-noise suits.

ULTRASOUNDINFRASON

Ultrasound- elastic vibrations with frequencies above the human hearing range (20 kHz), propagating in the form of a wave in gases, liquids and solids or forming standing waves in limited areas of these media.

Sources of ultrasound- all types of ultrasonic technological equipment, ultrasonic devices and equipment for industrial and medical purposes.

Normalized parameters of contact ultrasoundin accordance with SN 9-87 RB 98 are the sound pressure levels in one-third octave bands with geometric mean frequencies of 12.5; 16.0; 20.0; 25.0; 31.5; 40.0; 50.0; 63.0; 80.0; 100.0 kHz (Table 8.5).

Table 8.5

Maximum permissible levels of sound pressure of air ultrasound at workplaces

Harmful effects of ultrasoundon the human body manifests itself in a functional disorder of the nervous system, a change

215 blood pressure, composition and properties. Workers complain of headaches, rapid fatigue and loss of hearing sensitivity.

The main documents regulating safety when working with ultrasound are GOST 12.1.001-89 SSBT “Ultrasound. General safety requirements "and GOST 12.2.051-80 SSBT" Ultrasonic technological equipment. Safety requirements ", as well as SN 9-87 RB 98 "Ultrasound transmitted by air. Maximum permissible levels at workplaces ", SN 9-88 RB 98" Ultrasound transmitted by contact. Maximum Allowable Levels at Workplaces ”.

Direct contact of a person with the working surface of the ultrasound source and with the contact medium during the excitation of ultrasound in it is prohibited. Remote control is recommended; interlocks providing automatic shutdown in case of opening of soundproofing devices.

To protect hands from the adverse effects of contact ultrasound in solid and liquid media, as well as from contact lubricants, it is necessary to use sleeves, mittens or gloves (outer rubber and inner cotton). Anti-noise is used as PPE (GOST 12.4.051-87 SSBT "Personal protective equipment for hearing organs. General technical requirements and test methods").

Persons who are at least 18 years of age, have the appropriate qualifications, have been trained and instructed in safety precautions are allowed to work with ultrasound sources.

For the localization of ultrasound, the use of sound-insulating casings, half-housings, screens is mandatory. If these measures do not give a positive effect, then ultrasonic installations should be placed in separate rooms and cabins lined with sound-absorbing materials.

Organizational and preventive measures consist in instructing workers and establishing rational regimes of work and rest.

Infrasound- the area of \u200b\u200bacoustic vibrations in the frequency range below 20 Hz. In production conditions, infrasound, as a rule, is combined with low-frequency noise, in some cases - with low-frequency vibration. Infrasound is little absorbed in air and therefore is capable of propagating over long distances.

Many natural phenomena (earthquakes, volcanic eruptions, sea storms) are accompanied by the emission of infrasonic oscillations.

In industrial conditions, infrasound is formed mainly during the operation of low-speed large-sized machines and mechanisms (compressors, diesel engines, electric locomotives, fans,

turbines, jet engines, etc.), performing rotary or reciprocating motion with a repetition of the cycle less than 20 times per second (infrasound of mechanical origin).

Infrasound of aerodynamic origin arises during turbulent processes in flows of gases or liquids.

In accordance with SanPiN 2.2.4 / 2.1.8.10-35-2002 normalized parameters of constant infrasoundare the sound pressure levels in octave frequency bands with geometric mean frequencies of 2, 4, 8.16 Hz.

General sound pressure level - a value measured when the frequency response is “linear” (from 2 Hz) on the sound level meter or calculated by energy summation of sound pressure levels in octave frequency bands without corrections; measured in dB (decibels) and denoted by dB Lin.

Infrasound remote control at workplaces,differentiated for different types works, as well as permissible levels of infrasound in residential and public buildings and on the territory of residential buildings are established in accordance with Appendix. 1 to SanPiN 2.2.4 / 2.1.8.10-35-2002.

Infrasound has an adverse effect on the entire human body, including the hearing organ, lowering auditory sensitivity at all frequencies.

Prolonged exposure to infrasonic vibrations on the human body is perceived as physical activity and leads to fatigue, headache, vestibular disorders, sleep disorders, mental disorders, dysfunction of the central nervous system, etc.

Low-frequency vibrations with an infrasound pressure level of more than 150 dB are absolutely not tolerated by humans.

Measures to limit the adverse effects of infrasound on workers(SanPiN 11-12-94) include: attenuation of infrasound at its source, elimination of the causes of exposure; isolation of infrasound; absorption of infrasound, installation of mufflers; personal protective equipment; medical prevention.

The fight against the adverse effects of infrasound should be carried out in the same directions as the fight against noise. It is most expedient to reduce the intensity of infrasonic vibrations at the design stage of machines or units. Methods that reduce its occurrence and attenuation in the source are of paramount importance in the fight against infrasound, since methods using sound insulation and sound absorption are ineffective.

Infrasound is measured using noise meters (ShVK-1) and filters (FE-2).

PRODUCTION VIBRATIONS

Vibration- a complex oscillatory process that occurs when the center of gravity of a body is periodically displaced from the equilibrium position, as well as when the shape of the body is periodically changed, which it had in a static state.

Vibration occurs under the action of internal or external dynamic forces caused by poor balancing of rotating and moving parts of machines, inaccurate interaction of individual parts of units, shock processes of a technological nature, uneven workload of machines, movement of equipment on uneven roads, etc. Vibrations from the source are transmitted to other units and assemblies of machines and to objects of protection, i.e. on seats, work platforms, controls, and near stationary equipment - and on the floor (base). When in contact with vibrating objects, vibrations are transmitted to the human body.

In accordance with GOST 12.1.012-90 SSBT “Vibration safety. General requirements "and SanPiN 2.2.4 / 2.1.8.10-33-2002" Industrial vibration, vibration in residential and public buildings "vibration is divided into general, local and background.

General vibrationtransmitted through support surfaces to the body of a standing or sitting person. General vibration by source of occurrence is classified into categories.

Category 1- transport vibrations affecting humans at workplaces vehicle (tractors, agricultural machines, cars, including tractors, scrapers, graders, rollers, snow plows, self-propelled vehicles).

Category 2- transport and technological vibrations affecting a person at the workplaces of machines with limited mobility, which move only on specially prepared surfaces of industrial premises, sites. The sources of transport and technological vibration include: excavators, cranes, loading machines, concrete pavers, floor-standing industrial vehicles, workplaces of drivers of cars, buses, etc.

Category 3- technological vibrations affecting a person at workplaces of stationary machines or transmitted to workplaces that do not have sources of vibration. Sources of technological vibrations include: metal and woodworking machines, forging and pressing equipment, electric machines, fans, drilling rigs, agricultural machinery, etc.

Local vibrationtransmitted through the hands of a person or other parts of his body in contact with vibrating surfaces.

Vibration hazardous equipment includes jackhammers, concrete

crowbars, rammers, wrenches, grinders, drills, etc.

Background vibration- vibration recorded at the point of measurement and not associated with the investigated source.

Maximum permissible vibration level- the level of the vibration parameter, at which daily (except weekends) work, but not more than 40 hours per week during the entire working experience, should not cause diseases or deviations in the state of health detected modern methods research, in the process of work or in the remote periods of life of the present and subsequent generations. Compliance with the remote control for vibration does not exclude health problems in hypersensitive persons.

Vibration is characterized by the following parameters:

- vibration frequency f,Hz is the number of oscillation cycles per unit of time;

- displacement amplitude A, g- the greatest deviation of the oscillating point from the equilibrium position;

- vibration velocity v,m / s - the maximum value of the velocity of the oscillating point;

- vibration acceleration a,m / s 2 - the maximum of the values \u200b\u200bof the oscillating point acceleration.

Vibration velocity and vibration acceleration are determined by the formulas v \u003d 2rfA, a \u003d (2nf) 2.

According to sanitary standards, it is recommended to make a hygienic assessment of vibration affecting a person in a production environment frequency(spectral) analysis, integral assessmentby the frequency of the normalized parameter and dose of vibration.

The main normative documents in the field of vibration are GOST 12.1.012-90 SSBT “Vibration safety. General requirements ", as well as SanPiN 2.2.4 / 2.1.8.10-33-2002.

The main method characterizing vibration impact on a person is frequency analysis.

localvibration is set in the form of octave bands with geometric mean frequencies of 8; 16; 31.5; 63; 125; 250; 500 and 1000 Hz.

Normalized frequency range for generalvibration, depending on the category, is set in the form of octave or one-third bands with geometric mean frequencies of 0.8; 1.0; 1.25; 1.6; 2.0; 2.5; 3.15; four; five; 6.3; 8; ten; 12.5; 16, 20; 25; 31.5; 40; 50, 63, 80 Hz.

The normalized parameters of constant vibration are:

RMS values \u200b\u200bof vibration acceleration and vibration

speeds measured in octave (one-third octave) frequency bands,

or their logarithmic levels;

Frequency-corrected values \u200b\u200bof vibration acceleration and vibration velocity or their logarithmic levels.

The normalized parameters of unstable vibration are equivalent (in terms of energy), frequency corrected values \u200b\u200bof vibration acceleration and vibration velocity, or their logarithmic levels.

Maximum permissible valuesnormalized parameters generaland localindustrial vibration with a vibration exposure duration of 480 minutes (8 hours) are given in table. SanPiN 2.2.4 / 2.1.8.10-33-2002.

When frequency (spectral) analysisthe normalized parameters are the mean square values \u200b\u200bof the vibration velocity (and their logarithmic levels) or vibration acceleration for local vibration in octave frequency bands, and for general vibration in octave or 1/3-octave frequency bands.

Vibration affecting a person is normalized separately for each established direction, taking into account, in addition, for general vibration its category, and for local vibration - the time of actual exposure.

The effect of vibrations on the human body.Local vibration of low intensity can have a beneficial effect on the human body: restore trophic changes, improve the functional state of the central nervous system, accelerate wound healing, etc.

An increase in the intensity of fluctuations and the duration of their impact cause changes in the worker's body. These changes (disorders of the central nervous and cardiovascular systems, the appearance of headaches, increased excitability, decreased performance, disorder of the vestibular apparatus) can lead to the development occupational disease - vibration disease.

The most dangerous are vibrations with frequencies of 2 ... 30 Hz, since they cause resonant vibrations of many organs of the body, which have natural frequencies in this range.

Vibration protection measuressubdivided into technical, organizational and treatment-and-prophylactic.

To technical eventsinclude the elimination of vibrations in the source and on the path of their propagation. To reduce vibration in the source at the design and manufacturing stage of machines, favorable vibration working conditions are provided. Replacement of shock processes with non-shock ones, the use of plastic parts, belt drives instead of chain drives, the choice of optimal operating modes, balancing, improving the accuracy and quality of processing lead to a decrease in vibration.

During the operation of the technique, vibration reduction can be achieved by timely tightening of fasteners, elimination of backlash, gaps, high-quality lubrication of rubbing surfaces and adjustment of working bodies.

To reduce vibrations along the propagation path, vibration damping, vibration damping, and vibration isolation are used.

Vibration damping- reducing the amplitude of vibrations of machine parts (casings, seats, platforms for feet) due to the application of a layer of viscoelastic materials (rubber, plastics, etc.) on them. The thickness of the damping layer is usually 2 ... Zraza exceeds the thickness of the structural element on which it is applied. Vibration damping can be carried out using two-layer materials: steel! - aluminum, steel-copper, etc.

Vibration dampingis achieved by increasing the mass of the vibrating unit by installing it on rigid massive foundations or slabs (Fig. 8.5), as well as by increasing the rigidity of the structure by introducing additional stiffeners into it.

One of the ways to suppress vibrations is the installation of dynamic vibration dampers that are mounted on a vibrating unit, therefore, vibrations that are in antiphase with the vibrations of the unit are excited in it at every moment of time (Fig. 8.6).

Figure: 8.5. Installation of units on vibration damping Fig. 8.6. Scheme

basis: and- on the foundation and ground; dynamic

b- on the vibration damper cover

The disadvantage of a dynamic vibration damper is its ability to suppress vibrations of only a certain frequency (corresponding to its own).

Vibration isolationweakens the transmission of vibrations from the source to the base, floor, work platform, seat, handles of a mechanized hand tool by eliminating rigid connections between them and installing elastic elements - vibration isolators. Steel springs or springs, rubber gaskets, felt, as well as rubber-metal, spring-type springs are used as vibration isolators.

To prevent workers from contacting vibrating surfaces, fences, warning signs, and alarms are installed outside the working area. Organizational measures to combat vibration include the rational alternation of work and rest regimes. It is advisable to work with vibrating equipment in warm rooms with an air temperature of at least 16 ° C, since cold increases the effect of vibration.

Persons under the age of 18 and pregnant women are not allowed to work with vibrating equipment. Overtime work with vibrating equipment or tools is prohibited.

Therapeutic and prophylactic measures include industrial gymnastics, ultraviolet irradiation, air heating, massage, warm baths for hands and feet, taking vitamin preparations (C, B), etc.

From PPE, mittens, gloves, safety shoes with vibration-protective elastic-damping elements, etc. are used.

WORKPLACE LIGHTING

CHAPTER 11 PRODUCTION NOISE

CHAPTER 11 PRODUCTION NOISE

Noiserefers to any unwanted sound or combination of such sounds. Sound is a wave-like oscillatory process propagating in an elastic medium in the form of alternating waves of condensation and rarefaction of particles of this medium - sound waves.

Any oscillating body can be the source of sound. When this body comes into contact with the environment, sound waves are generated. Concentration waves cause an increase in pressure in an elastic medium, and rarefaction waves - a decrease. Hence the concept sound pressureis the alternating pressure that occurs when sound waves pass in addition to atmospheric pressure.

Sound pressure is measured in Pascals (1 Pa \u003d 1 N / m 2). The ear of a person senses a sound pressure from 2-10 -5 to 2-10 2 N / m 2.

Sound waves are energy carriers. Sound energy per square meter of surface area perpendicular to the propagating sound waves, called the power of soundand is expressed in W / m 2. Since a sound wave is an oscillatory process, it is characterized by concepts such as oscillation period(T) is the time during which one complete oscillation occurs, and vibration frequency(Hz) - the number of complete oscillations in 1 s. The set of frequencies gives noise spectrum.

Noises contain sounds of different frequencies and differ from each other in the distribution of levels for individual frequencies and the nature of the change general level in time. For a hygienic assessment of noise, the sound frequency range from 45 to 11,000 Hz is used, including 9 octave bands with geometric mean frequencies of 31.5; 63; 125; 250; 500; 1000; 2000; 4000 and 8000 Hz.

The organ of hearing distinguishes not the difference, but the frequency of changes in sound pressure, therefore, the intensity of sound is usually evaluated not by the absolute value of sound pressure, but by its level,those. the ratio of the generated pressure to the pressure taken as a unit

comparisons. In the range from the hearing threshold to the pain threshold, the sound pressure ratio changes by a factor of a million, therefore, to reduce the measurement scale, the sound pressure is expressed through its level in logarithmic units - decibels (dB).

Zero decibels corresponds to a sound pressure of 2-10 -5 Pa, which approximately corresponds to the threshold of audibility of a tone with a frequency of 1000 Hz.

Noise is classified according to the following criteria:

Depending on the the nature of the spectrumemit the following noises:

broadband,with a continuous spectrum more than one octave wide;

tonal,in the spectrum of which there are pronounced tones. The tonal nature of the noise is established by measuring in one-third octave frequency bands by the excess of the level in one band in comparison with the neighboring ones by at least 10 dB.

By timing characteristicsdistinguish between noises:

permanent,the sound level of which over an 8-hour working day changes in time by no more than 5 dBA;

fickle,the noise level of which for an 8-hour working day changes in time by at least 5 dBA. Intermittent noises can be classified into the following types:

- hesitantin time, the sound level of which is continuously changing over time;

- intermittent,the sound level of which changes stepwise (by 5 dB-A or more), and the duration of the intervals during which the level remains constant is 1 s or more;

- pulse,consisting of one or more sound signals, each of which has a duration of less than 1 s; in this case, the sound levels measured, respectively, on the “impulse” and “slow” time characteristics of the sound level meter differ by at least 7 dB.

11.1. sources of NOISE

Noise is one of the most common adverse factors in the working environment, the impact of which on workers is accompanied by the development of premature fatigue, a decrease in labor productivity, an increase in general and occupational morbidity, as well as injuries.

At present, it is difficult to name a production that does not have elevated levels of noise in the workplace. The most noisy are the mining and coal, machine-building, metallurgical, petrochemical, timber and pulp and paper, radio engineering, light and food, meat and dairy industries, etc.

So, in cold heading shops the noise reaches 101-105 dBA, in nail shops - 104-110 dBA, in braiding shops - 97-100 dBA, in the polishing departments - 115-117 dBA. At the workplaces of turners, milling cutters, mechanics, blacksmiths-stampers, the noise level ranges from 80 to 115 dBA.

At factories of reinforced concrete structures, the noise reaches 105-120 dBA. Noise is one of the leading occupational hazards in the woodworking and logging industries. So, at the workplace of the frame cutter and the cutter, the noise level ranges from 93 to 100 dBA with a maximum of sound energy in the medium and high frequencies. The noise in the carpentry shops fluctuates within the same limits, and logging operations (felling, skidding of timber) are accompanied by a noise level of 85 to 108 dBA due to the operation of skidding winches, tractors and other mechanisms.

The overwhelming majority of production processes in spinning and weaving mills are also accompanied by the formation of noise, the source of which is the striker mechanism of the weaving machine, blows of the shuttle drive. The highest noise level is observed in weaving shops - 94-110 dBA.

The study of working conditions in modern garment factories showed that the noise level at the workplaces of sewing machine operators is 90-95 dBA with a maximum of sound energy at high frequencies.

The most noisy operations in mechanical engineering, including aircraft construction, automobile construction, car building, etc., should be considered cutting and riveting work using pneumatic tools, performance tests of engines and their units of various systems, bench tests for vibration strength of products, drum cooking, grinding and polishing parts, stamping blank.

The petrochemical industry is characterized by high-frequency noises of various levels due to the discharge of compressed air from a closed technological cycle of chemical production or

from compressed air equipment such as assembly machines and vulcanizing lines in tire factories.

At the same time, in mechanical engineering, as in no other industry, the largest volume of work falls on machine tool metalworking, which employs about 50% of all workers in the industry.

The metallurgical industry as a whole can be classified as an industry with a pronounced noise factor. Thus, intense noise is typical for smelting, rolling and pipe rolling industries. Of the industries related to this industry, noisy conditions are characteristic of hardware factories equipped with cold heading machines.

The most noisy processes include noise from an open air jet (blowing) escaping from small diameter holes, noise from gas burners and noise generated when metals are sprayed onto various surfaces. The spectra from all these sources are very similar, typically high-frequency, without a noticeable drop in energy up to 8-10 kHz.

In the forestry and pulp and paper industries, woodworking workshops are the most noisy.

The building materials industry includes a number of noisy industries: machines and mechanisms for crushing and grinding raw materials and the production of precast concrete.

In the mining and coal industries, the most noisy operations are mechanized mining operations both with the use of hand-held machines (pneumatic perforators, jackhammers) and with the help of modern stationary and self-propelled machines (combines, drilling rigs, etc.).

The radio engineering industry is generally comparatively less noisy. Only its preparatory and procurement shops have equipment typical for the machine-building industry, but in much smaller quantities.

In light industry, both in terms of noise and the number of employed workers, spinning and weaving industries are the most unfavorable.

The food industry is the least noisy of all. Its characteristic noises are generated by flow units of confectionery and tobacco factories. However, some machines of these industries generate significant noise, for example, cocoa mills, some sorting machines.

Each branch of industry has workshops or separate compressor stations that supply the production with compressed air or pumping liquids or gaseous products. The latter are widely used in the gas industry as large independent farms. Compressor units generate intense noise.

Examples of noises typical for various industries, in the absolute majority of cases, have a common spectral shape: they are all broadband, with a slight drop in sound energy in the low (up to 250 Hz) and high (above 4000 Hz) frequencies with levels of 85-120 dBA. Exceptions are aerodynamic noises, where sound pressure levels rise from low to high frequencies, as well as low frequency noises, which are significantly less in industry than those described above.

All the described noises characterize the most noisy industries and areas where physical labor predominates. At the same time, less intense noises are also widespread (60-80 dBA), which, however, are hygienically significant during work associated with nervous stress, for example, at control panels, during computer processing of information and other works that are becoming increasingly common.

Noise is also the most common adverse factor in the working environment in the workplace of passenger, transport aircraft and helicopters; rolling stock of railway transport; sea, river, fishing and other vessels; buses, trucks, cars and special vehicles; agricultural machinery and equipment; road construction, land reclamation and other machines.

The noise levels in the cockpits of modern aircraft fluctuate in a wide range - 69-85 dBA (long-haul aircraft for medium and long-range airlines). In the cabs of medium-duty vehicles under various modes and operating conditions, sound levels are 80-102 dBA, in the cabs of heavy vehicles - up to 101 dBA, in cars - 75-85 dBA.

Thus, for the hygienic assessment of noise, it is important to know not only its physical parameters, but also the nature of the work activity of the human operator, and, first of all, the degree of his physical or nervous load.

11.2. biological effect of noise

Professor E.Ts. Andreeva-Galanina. She showed that noise is a general biological irritant and affects not only the auditory analyzer, but, first of all, affects the structures of the brain, causing shifts in various systems of the body. Manifestations of noise impact on the human body can be conditionally subdivided into specificchanges occurring in the organ of hearing, and non-specificarising in other organs and systems.

Aural effects. Changes in the sound analyzer under the influence of noise constitute a specific reaction of the body to acoustic exposure.

It is generally accepted that the leading sign of the adverse effect of noise on the human body is a slowly progressive hearing loss of the type of cochlear neuritis (and, as a rule, both ears are affected equally).

Occupational hearing loss refers to sensorineural (perceptual) hearing loss. This term refers to hearing impairment.

Hearing loss under the influence of sufficiently intense and long-acting noises is associated with degenerative changes both in the hair cells of the organ of Corti and in the first neuron of the auditory tract - the spiral ganglion, as well as in the fibers of the cochlear nerve. However, there is no consensus on the pathogenesis of persistent and irreversible changes in the receptor region of the analyzer.

Occupational hearing loss usually develops after a more or less long period of work in noise. The timing of its occurrence depends on the intensity and frequency-time parameters of the noise, the duration of its exposure and the individual sensitivity of the hearing organ to noise.

Complaints about headache, increased fatigue, tinnitus, which can occur in the first years of work in a noise environment, are not specific to the lesion of the auditory analyzer, but rather characterize the reaction of the central nervous system to the effect of a noise factor. The sensation of hearing loss usually occurs much later than the appearance of the first audiological signs of damage to the auditory analyzer.

In order to detect the earliest signs of the effect of noise on the body and, in particular, on the sound analyzer, the most widely used method is to determine the temporal displacement of hearing thresholds (TSP) at different exposure times and the nature of the noise.

In addition, this indicator is used to predict hearing loss based on the relationship between constant shifts in the thresholds (losses) of hearing (HRL) from noise, acting during the entire time of work in noise, and temporary shifts in the thresholds (HRT) during daytime exposure. the same noise, measured two minutes after exposure to noise. For example, in weavers, the temporary displacements of the hearing thresholds at a frequency of 4000 Hz for a daytime exposure to noise are numerically equal to constant hearing losses at this frequency for 10 years of work in the same noise. On this basis, it is possible to predict the resulting hearing loss by determining only the shift in the threshold for the daytime exposure to noise.

Noise accompanied by vibration is more harmful to the organ of hearing than isolated.

Extra-aural effects of noise. The concept of noise sickness developed in the 1960s and 1970s. on the basis of works on the effect of noise on the cardiovascular, nervous and other systems. At present, it has been replaced by the concept of extra-aural effects as non-specific manifestations of noise.

Workers exposed to noise complain of headaches of varying intensity, often with localization in the forehead (more often they occur at the end of work and after it), dizziness associated with a change in body position, depending on the effect of noise on the vestibular apparatus, memory loss , drowsiness, increased fatigue, emotional instability, sleep disturbance (intermittent sleep, insomnia, less often drowsiness), pain in the heart, decreased appetite, increased sweating, etc. The frequency of complaints and their severity depend on the length of service, the intensity of noise and its nature ...

Noise can interfere with the function of the cardiovascular system. Changes in the electrocardiogram were noted in the form of a shortening of the Q-T interval, lengthening of the P-Q interval, an increase in the duration and deformation of the P and S waves, a shift in the T-S interval, a change in the voltage of the T wave.

The most unfavorable from the point of view of the development of hypertensive conditions is broadband noise with a predominance of high-frequency components and a level above 90 dBA, especially impulse noise. Broadband noise causes maximum shifts in the peripheral circulation. It should be borne in mind that if there is addiction (adaptation) to the subjective perception of noise, then in relation to the developing vegetative reactions, adaptation is not observed.

According to an epidemiological study of the prevalence of major cardiovascular diseases and some risk factors (overweight, burdened anamnesis, etc.) in women working under conditions of constant occupational noise in the range from 90 to 110 dBA, it was shown that noise, as a separate factor (excluding general risk factors), may increase the frequency arterial hypertension (AH) in women under the age of 39 (with less than 19 years of experience) by only 1.1%, and in women over 40 - by 1.9%. However, when noise is combined with at least one of the "common" risk factors, one can expect an increase in hypertension by 15%.

When exposed to intense noise of 95 dBA and above, there may be a violation of vitamin, carbohydrate, protein, cholesterol and water-salt metabolism.

Despite the fact that noise affects the body as a whole, the main changes are noted on the part of the hearing organ, the central nervous and cardiovascular systems, and changes in the nervous system may precede disorders in the hearing organ.

Noise is one of the most powerful stressors in the workplace. As a result of exposure to high-intensity noise, changes occur simultaneously in both the neuroendocrine and immune systems. This stimulates the anterior lobe of the pituitary gland and increases the secretion of steroid hormones by the adrenal glands, and as a consequence, the development of acquired (secondary) immunodeficiency with involution of lymphoid organs and significant changes in the content and functional state of T- and B-lymphocytes in the blood and bone marrow. Arising defects immune system relate mainly to three main biological effects:

Decreased anti-infectious immunity;

Creation of favorable conditions for the development of autoimmune and allergic processes;

Decreased antitumor immunity.