UAZ Description of the work scheme of Gora. Description Gur on UAZ. Lubrication of steering connections UAZ wagon layout with gur

The steering UAZ Hunter consists of a steering mechanism with a hydraulic switch, the steering column with the steering and the cardan shaft, the steering wheel and the steering drive that includes two steering thrust connected by ball hinges with turning fists of the front suspension.

The steering wheel is installed on the shlits of the shaft of the steering column and attached to the shaft with a nut. The steering shaft is installed in the steering column pipe on two bearings and transmits torque from the steering wheel to the steering mechanism through the drive shaft consisting of a slotted shaft, a sliding fork and cardan hinges.

The steering mechanism of the type screw is the ball nut - the sector, installed in the rotor space, the steering mechanism is attached to the frame with bolts. Compounds of hoses with a steering mechanism are sealed with copper beds. The steering hydraulic tank tank is installed in the open space on the left mudguard bracket and is connected by a hose with a hydraulic pressure pump and with a leading fluid return.

For cars UAZ-31519 Hunter with the engine UMP-421.

For cars UAZ-315195 Hunter with the engine ZMZ-409.

The steering trapezium consists of a compassion, tights of the steering tower and the tape of a steering trapezing, adjustable along the length, tips of the steering, which have a different direction of the thread, depending on the installation side, the rotting fist lever, swivel fists and ball pusshers.

Steering UAZ Hunter with power steering, work principle.

The screw of the steering mechanism when rotating the steering wheel is screwed or turned out of the piston nut, which, in turn, moves along with a spool. The fluid pressure in one of the cavities of the steering mechanism increases - the nut-piston moves. Having moved, the nut-piston turns the shaft of the steering tower, which, in turn, turns controlled wheels through the tape of the steering trapez. The working fluid, passing through the steering mechanism, arrives back into the tank of the hydraulic plug on the discharge hose.

In the power hydrauloveel, the working fluid pressure is created by a paddle type pump installed on the engine bracket. The pump is driven by a polyclinic strap from the pulley of the crankshaft of the engine. The consumables installed in the pump supports the required pressure of the working fluid in the steering hydraulic system system, depending on the rotation frequency of the crankshaft.

Noise in the power steering system UAZ Hunter.

When turning the front wheels to the right or left until it stops in the power steering system, noise may appear or hum, which occurs due to the output of the hydraulic pressure pump for maximum pressure. Such noise or hum is characteristic sign The operation of the pump and does not affect the operability of the steering in general.

On cars with a steering mechanism 31519-3400011-10, the cardan hinge is attached to the steering shaft bolt, and on the steering mechanism 31519-3400011-20: the wedge with the washer and nut.

Failure of the power steering on UAZ Hunter.

If the power failure is refused, the ability to control the car is preserved, but the effort on the steering wheel increases noticeably. In the absence of oil in the hydraulic power system, due to damage to the pump or the destruction of the hoses, it is necessary to remove the drive belt, otherwise it is possible to join the hydraulic feller pump and the belt break.

When the pump drive belt on the UAZ Hunter with the ZMZ-409 engine, it is necessary to control the coolant temperature, as the engine overheating is quite possible. The long-term operation of the car with a non-working hydraulicer leads to premature wear of the parts of the steering mechanism.

Inspection and inspection of the steering mechanism UAZ HANTER with a power steering power plant.

Service steering mechanism UAZ HANTER with power steering.

It is to check the tension of the hydraulic tape drive belt, checking the tightness of the hoses and their connections, checking the lack of leakage seals and the steering mechanism, check the level and replace the working fluid in the hydraulic tank.

The working fluid in the power steering system must match the Dexron IID specification. In more detail, the process of replacing the working fluid and filter in the tank of the power steering tensioner, as well as the parameters of the tension of the hydraulic steering wheel drive of the power steering pump on UAZ HANTER, is set forth in.

Maintenance of the steering with a power steering wheel on cars UAZ-374195, UAZ-396295, UAZ-396255, UAZ-390995, UAZ-390945, UAZ-220695, UAZ-330395, UAZ-330365 lies in periodic checking of the steering mechanism Following steering, thaw, swivel lever, checking the free power steering, timely lubrication of steering hinges, tall or changing the oil in the oil pot of the steering power system.

Features of the operation of the power steering UAZ wagon layout.

When rotating controlled wheels to the right or left until it stops in the hydraulic steering system, noise may appear noise or a hum that occurs as a result of the output of the hydraulic pressure pump for maximum pressure. This noise or hum is a characteristic sign of the pump and does not affect the performance of the steering. In order to avoid the failure of the pump hydraulic power and overheating of the oil, it is not recommended to hold the steering wheel in extreme positions for more than 20 seconds.

When disagreeing the hydraulic agent, as a result of damage to the pump, the destruction of the hose or the drive belt or towing the car due to the engine stop, use the steering mechanism only briefly. In the absence of oil in the hydraulic power system, it is necessary to remove the pump drive belt, otherwise the pump is permanent and the belt break.

With the removal of the hydraulic power pump drive belt, it is necessary to especially carefully control the fluid temperature, as the engine overheating is possible. The long-term operation of the car with a non-working power steering leads to premature wear of the steering mechanism.

Maintenance of the power steering UAZ wagon layout with a hydraulic pole (GUR) of the steering wheel.

When the gaps appear in the conical connections of the levers and the steering torments, it is necessary to wrap the hinge plug stop, and then turn it out on 1/2 turnover and in this position again to bore. The first fastening of the steering mechanism must be made through 500 kilometers of the mileage of the new car, in the future, in accordance with the requirements of the service book.

Checking and eliminating the total backlog control of the Wagon layout with GUR.

On Cars Wagon Layout with a steering power steering, total backlash must be checked when the engine is operation in idling mode. The total backlop backlash is checked when the movement mounted in the right front wheels, shaking the steering wheel from the position of the corresponding start of the rotation of the controlled wheels in one direction, to the position of the steering wheel of the corresponding start of the rotation of the controlled wheels in the opposite direction.

The state of the steering mechanism is considered normal and not requiring adjustment if the total backlash or the free step of the steering wheel does not exceed 20 degrees, which corresponds to 74 mm when measured on the rim of the steering wheel.

For cars UAZ wagon layout with power steering with the free power steering wheel, it is necessary to determine at the expense of which node it turns out an enlarged backlash, for what to check: the reliability of the tightening of the steering crankcase bolts, the state of steering hinges, tightening the wedge of fastening and clearances in hinge and spline connections of the steering column of the steering column, as well as the presence of gaps in the steering mechanism.

When the radial gap is detected in the steering shaft hinge, the axial movement of the crossbars in the bearings, it is necessary to make an additional elimination of bearings in the ears of the forks. Deculsion to produce in such a way as to prevent the bearing cup crumpled. With the presence of gaps in the cutter channels of the steering column, the shaft must be replaced with the shaft. When the gaps are detected in the steering mechanism, it is necessary to adjust it.

Lubrication of steering connections UAZ wagon layout with gur.

The lubricant of the steering hinges is made using a lever-plunger syringe through press oil. Lubrication is fed to its output through the upper sealing washers. Lithol-24 or Lithol-24PK is used as a lubricant. In addition, any other lithium lubricant category NLGJ 3 can be applied.

The steering system of the steering is all confined to the DEXRON IID or DEXRON III transmission oil in the amount of 1.3 liters. Dexron III can be addressed in Dexron IID. When checking the oil level in the oil tank of the power steering, the front wheels of the car must be installed directly. The oil is agreed to the level of the oil tank filter grid. Partial refueling of the steering hydraulic power system is performed in the following order:

1. Disconnect the tower cravings from the bump or post the front wheels, remove the oil tank cover of the hydraulic tank, fill the oil to the filter grid level.

2. Do not start the engine, turn the steering wheel or the input shaft of the mechanism from the stop until it stops until the exit of the air bubbles from the oil in the tank. Follow the oil into the tank.

3. Run the engine at the same time fueling the oil into the tank. Give the engine to work 15-20 seconds and pump the hydraulic power system to remove residual air from the steering mechanism by turning the steering wheel from the stop until it stops, without delaying in extreme positions, three times in each direction.

4. Check the oil level in the tank and bring it to the level of the filter grid. On the heated engine, when the oil is heated in the hydraulic system, it is allowed to lift the oil level in the tank above the grid to 7 mm. Close the cover with a lid and tighten the cover of the cover with an effort. Attach the tsyka cravings, tighten and shrink the ball finger nut.

In case of plentiful foaming of oil in the tank, which indicates air intake in the system, the engine is muffled and allow oil to stand for at least 20 minutes to the exit of bubbles from the oil. Inspect the places of connecting hoses to the units of the hydraulic system and, if necessary, eliminate not tightness. Full oil replacement and filter in the steering hydraulic system system is considered in the material.

With contamination of the consumables and safety valves of the hydrowelder of the steering wheel, they must be rinsed. For this:

1. Unscrew the plug located above the pump outlet. Remove the spring and spool of the expendable valve, and set the plug in the place that it will prevent oil leakage.

2. Unscrew the safety valve seat, remove the ball, the springs and spring guide. Remove the ring and filter from the seat of the safety valve.

3. Rinse the details and blow them with compressed air. Build in reverse order. When assembling, follow purity. When disassembling and assembling, not to disrupt the adjustment of the safety valve, do not change the number of adjustment pads.

Pump Drive Drive Tension Hydrausselleter and Fan Systems on UAZ-374195 cars, UAZ-396295, UAZ-396255, UAZ-390995, UAZ-390945, UAZ-220695, UAZ-330395, UAZ-330365 with ZMZ-4091 and ZMZ- 40911 is performed by moving the pump of the hydroxidant along the mounting bracket to the engine.

To do this, we need to loosen the pump mounting bolts to the bracket, move the pump with a tensioning screw to normal tension of the drive belt and tighten the pump mounting bolts. The belt deflection must be within 5-8 mm when applied to it in 4 kgf. The drive belt is subject to replacement in case of detection of damage on it or with excessive stretching.

The car UAZ patriot in the design of the steering mechanism has a device that the people are called the GUR or hydraulic steering amplifier. The hydraulicel is a device by which human physical work is facilitated. All that is necessary for a person is to keep the steering wheel in the hands, but you can even control it with one finger. In this material, we consider the appointment of GUR, as well as its device and the principle of repair work on the SUV of UAZ Patriot.

The main purpose of the GUR device is to relieve the car. Due to the presence of a power steering at SUV Patriot, turn the ram is much easier and more comfortable. After all, turn the steering wheel without an amplifier on such a 2-ton car is quite difficult, and it can provoke the development of an emergency while driving. In addition, long-term control of the car would lead to the rapid fatigue of the driver. Therefore, such a device was developed, which made it possible to facilitate human labor.

The hydraulicel is complex mechanismwhich includes the following main devices:

- Pump.

- Hydraulic cylinder.

- Distributor.

- Connecting hoses.

- Tank for refueling the working fluid.

Consider the assignment of each of the elements of the GUR.

Pump 1 is used to be able to maintain pressure and ensuring the circulation of the working fluid on the system. The pump is a mechanism that is attached to the car's motor and operates by belt transmission from the crankshaft of an SUV.

The hydraulic cylinder is designed to ensure the rotation of the wheels under the action of fluid pressure. The hydraulic cylinder is built into the steering system 3, whereby this function is ensured. Below is a constructive scheme of the power steering device by car UAZ Patriot.

The distributor 2 is intended to distribute the working fluid flow into the desired cavity of the hydraulic cylinder. The distributor is the device by means of which the direction of a certain amount of fluid into the hydraulic cylinder or the tank is ensured.

The tank 6 is a plastic reservoir for storing and topping the working fluid into the system. In the tank, in addition to the liquid, a special filter is also located and the oil control probe.

Do not do in the design of the GUR steering wheel on the UAZ Patriot SUV without connecting hoses 5. These hoses are designed to work under high pressure, so they must provide high tightness of the system.

The circulation of fluid at the expense of hoses is provided between the hydraulic cylinder and the distributor. Low pressure hoses ensure the flow of liquid from the tank into the pump and from the distributor to the tank.

Principle of operation of the device

The functioning of the GUR on the UAZ SUV patriot is based on the movement of the spool when the steering wheel is rotated in different directions. During the rotation of the wheel, when making a maneuver, the spool is moving, whereby the discovery of drain highways is carried out. During the opening of a specific highway, the oil movement under pressure in the necessary areas of the device. The fluid is pressureing on the piston, and in the end drives the rotation of the wheels. When the driver ceases to rotate the steering wheel, the spool stops and the neutral position of the distributor housing is stopped.

There is a flow of fluid from the injection line into the drain, whereby the pump carries out the oil pumping through the system. In case of failure of the hydraulic pump, the loss of controlling the car is not at all, which is another advantage of this mechanism.

Repair grounds

Each mechanism tends to break and gur on SUV UAZ Patriot is no exception. The grounds for carrying out the following features:

- The appearance of the extraneous noise of the device.

- The appearance of leaks of oil on the elements of the mechanism.

- The emergence of microcracks on low and high pressure.

- Increasing the efforts to be applied to the steering wheel.

- Reducing the level of fluid in the tank.

Repair of GUR SUV UAZ Patriot can be carried out with their own hands, but it all depends on the type of malfunction, so it is necessary to find out the reason for the beginning. Available the following reasonsWhile repairing the device:

- If an uncharacteristic noise of its functioning occurs in the device mechanism, it indicates the wear of the bearing elements. It should be replaced. But, besides this, the outsiders can be caused by a third-party fall into the liquid or when refilling the system of unsuitable liquid.

- If the leakage of the working fluid is detected, then the place of such actions should be found. At the same time, it is important to examine all the places of connection of the hoses, where the working fluid is most often occurring.

- If the oil level is reduced in the GUR tank, this indicates the need to replace the tank or connecting hoses soon.

- The presence of microcracks on high pressure hoses is a key feature that soon the device may fail during operation. Therefore, during the prevention when the cracks on the hoses are detected, the latter must be replaced. High pressure hoses repair is not accomplished and after their wear, they are recycled.

- With an increase in the load on the steering wheel, the hose breaks, which requires immediate replacement.

If you resort to verification measures of the device integrity, it is important to perform a number of the following actions:

- check the fluid level in the tank;

- check the service of the tank;

- check the integrity of the hoses for the presence of microcracks and oil flows;

- to check the integrity of the pump;

- check the condition of the liquid in the tank.

Repair of GUR on the UAZ Patriot SUV, usually includes, seals, bearings and hoses, and can be implemented independently.

More complex repairs with the failure of the pump, the distributor or the hydraulic cylinder is better to entrust professionals. At this stage, you can sum up and note that the GUR on UAZ patriot is a key element between steering and driver, so the serviceability of this device is displayed mainly on the safety of passengers and the driver.

You can check your KBM, and if you need to reduce it!

Recently, almost every manufacturer equips its cars amplifier, it can be both hydraulically and electric. The last type is actively used on the domestic "farewell" of the first and second generations. On cars of the Ulyanovsk Automobile Plant, namely, "Patriot", use a classic hydraulic amplifier. But many wonder: why not install the GUR on the UAZ of other models? Indeed, there are many cars that are still not equipped with such an option. This is "loaf" and the 469th UAZ, the people referred to as "goat". In today's article, we will look at how to do it with your own hands.

Characteristic

At the moment, almost all budget cars are equipped with such an amplifier. However, the owners of old cars have a desire to retrieve the car with Gurom. This is a very useful option. Even with a large diameter of the steering wheel, the efforts attached to the control of the machine will be several times less. This is especially noticeable when parking in densely populated cities. Gur itself is a part of the car and works on which pump shakes. Also here enters and the steering column. The usual factory is not suitable here. There are many advantages of this system.

The first is the comfort of control, because no longer need to twist the "Barank" as before. Second - reliability. The hydraulic amplifier practically does not fail. The third advantage is the simplicity of service. When operating such a car you will not have difficulties. Even if the amplifier breaks, it can be fixed with your own hands. And you take such a breakdown to the garage completely. The only thing that will be - the ease of control will deteriorate. The steering wheel will become "heavy." By the way, for the first time such an amplifier was installed on the Gorky "Seagull". GAZ-13 was the first car with gur.

Cons of refinement

Among the shortcomings of the installation of GUR on the UAZ-469, it is necessary to note the bad informativeness of the steering wheel at speeds of more than 60 kilometers per hour. If without an amplifier, he becomes tougher, then with GUR, it is also easily spinning, as at 10 km / h.

On the other hand, UAZ - the machine is not for racing. Therefore, if the budget allows, such a refinement is quite acceptable. By installing the GUR on the UAZ-469 from a foreign car, you will reduce the load on your hands three times, crossing off road or parked in a close courtyard.

What do we need to buy?

To do this, we need to purchase a steering column under the amplifier, as well as the pump. The latter will create and maintain the necessary pressure in the control system. The operation of the element is carried out by a drive belt. We will also need a tank for storing liquid and connecting hoses. The latter are divided into two types - low and high pressure. The first will drive a "reverse" in the tank, and the second serves to circulate the fluid in the system itself. As for the amount of fluid, which is activated in the system, it is not too much. For UAZ, there is a 1.2 liter of special oil. It differs from motor-viscosity and consistency.

How to install?

To do this, you need to remove the steering wheel. Here you will need not just a set of keys, and the puller. Just not to dismantle the steering wheel. It looks like this puller so:

It will be impossible to dismantle the wheel with bare hands - you only damage the steering column. After disassembling the steering wheel, the column is also needed to remove. The nut, fastening the tower steering thrust is extracted. Next, the three nuts of the steering element are unscrewed. After that, a new tower kit is installed on the column column with gur. The latter must be combined with a steering wheel and fix with hopnesses. When installing a new column "Under GUR", we will interfere with the old mount. It is cut with a grinder. Further install plastic protective casing on the column. Screws for fasteners are suitable old. Next, a rubber ring is put on the casing, a crown nut and washer. The penultimate fasten with the help of a stepladder.

A small drive shaft is installed between the steering and column, which will connect both items and securely transmit the force. Wedge is scored in a wide hole (with a hammer, light blows). Two washers are mounted on the wedge - spring and ordinary. As a result, the length before the hinge should be 300 millimeters. Next twist the crown nut and mount the steering wheel. The steering column Gur (UAZ-469 - Tuning object) is successfully installed. But that's not all. We need to fix the remaining details of the mechanism.

Installing the pump and tank

Any hydraulic amplifier is activated by fluid pressure. To create it, there is a pump. But it works through the belt transmission - from the pulley of the crankshaft. It is worth noting that there are different belts - under the GUR on the UAZ and for cars without it. We will need a longer element - under the hydraulic power steering. So, remove the drive belt, the impeller of the fan and the crankshaft pulley.

Next, we unscrew the water pump. Fresh the impeller of the radiator on the wheel hub. We will also need the elongated bolts "under the GUR" on the UAZ and spacer (usually comes in the kit). The new strap is installed. The fuel filter bracket is also removed. There will be a pump. The bracket, which comes in a set of gur, is mounted on the place of the pump piping. Next on the brackets pin the pump. The bar and bracket are fixed on the lock nut. When the belt is installed, it is necessary to set the correct tension. The gur adjustment (UAZ "SIBIR" can also be upgraded) is performed by tensioning a special roller. How to determine the normal stretch? The belt should not hang on the pulleys. If you press it with your finger, it will be bombed by 10-15 millimeters, while rotating at a right angle relative to the plot plane. After we installed on the UAZ, install the fuel filter back. It is attached to a square hole. Next, we take into the hands of a drill and drill in the place of the left mudguard of the motor several holes.

They are needed for fastening a tank with liquid. Here we will need bolts, nuts and clashes. This element is connected to the pump with a polymer hose. Works system on conventional transmission oil. Once again, check the correctness of the installation of parts and bring the car.

Check

On the heated engine, a steering wheel from side to side. In the first seconds, excess air should go out of the tank. If he started foaming, it means that the system is notching and need to look for a breakdown. After thorough sealing of all hoses, we start the motor and check the work of the amplifier again. GUR, on the UAZ "Buanka" from a foreign car established, should act smoothly and silently. The belt does not whistle, there are no leaks of the working fluid.

You will immediately feel the work of this amplifier. The steering wheel is spinning much easier than before. When operating, regularly monitor the residue of the liquid in the plastic tank. It must be addressed if necessary. The operation of the hydraulic amplifier with an insufficient fluid level threatens the pump breakdown. The steering wheel will be much harder.

Problems of operation

Often, car owners acquire ready-made kits of amplifiers from the Ulyanovsk plant. Their cost is relatively small, and they are not problematic in the installation. Ready kits can be purchased at a price of 20 to 37 thousand rubles. But with frequent operation, especially without a proper level of oil, the amplifier begins to buzz. This means that the pump or drive belt was damaged. It is less likely to break down (it can flow in places of seal). It is not recommended to ride with such a breakdown.

GUR from "BMW"

Often the question is raised to establish GUR (UAZ) from foreign cars, namely the BMW seventh series. It would seem that these are two completely different cars. But the German GUR is quite adequately working at the Ulyanovsky "Koz". To do this, you will need a pump at 130 and more bar and flat pulley.

The latter can be chopped at Tokart under the order. It is necessary for the coaxiality of the crankshaft and pump. Some set a two-bit element from the 24th Volga. Tank hoses are suitable without alter. The rest of the installation is no different.

Conclusion

So, we found out how to put a hydraulic amplifier on the UAZ. After such a refinement, the car control will become more comfortable, and the driver's fatigue will decrease at times. This is a very useful tuning for such an SUV. And if you consider that large wheels are installed on the car, the GUR becomes simply necessary.

Information is given for "Borisovsky" Gora for the Volga!

When three months ago I had to put a short belt and turn off the GUR, I even experienced some positive emotions. The Sip of this "whispered helper" was disappeared, and when moving, such a forgotten reactive force on the steering wheel appeared. The car began to feel. Dragged only the need to sweat and park in several races. Soon I, by the way, is at all accustomed, and the role of the amplifier began to perform my muscles. But choose the moment when Gur has earned again, I'm not able to. It was shock! The car was simply transformed.

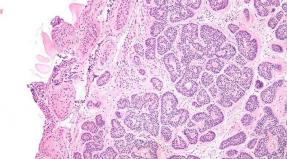

My GUR SDOH after 30 tons km. He stopped helping left. An autopsy showed that he could not act in a different way. The upper oil seal was destroyed, its edge cut off. In addition, it is not at all clear what designers were calculated, making such a design. Below is a schematic representation of the gur. Do not consider this scheme strictly. It depicts two shafts. Vertical shaft - close to us - shaft of the bump. It has a toothed sector entering the teeth on the piston. The sector is not visible, he is directed from us.

Both shafts from both ends are arranged cavities connected to the drain. For example, at the end of the shaft of the ball nut (where the steering column's cardan) is needed so as not to transmit all pump pressure on the gland. Three more areas are shown in the figure. The cavity 1 is between the two seals of the shaft shaft - connects through the channel in the shaft with the cavity 2 - under the top cover of the shaft shaft (where the adjusting bolt) is connected. Next, by passing two technological holes (they are drilled in the crankcase and shut up with small balls - the tradition of the Belarusians to stack the balls with the balls, so that they then fall out :-)) the cavity 2 goes into the cavity of the 3 - the bottom bearing of the ball nut. And further, having passed through the channel in the center of the shaft of the ball nut, we fall into the cavity 4 - under the top cover of the shaft of the ball nut. It is connected to the drain highway.

Once at the ends of the shafts there are cavities of the drain, that is, and rings that prevent oil to merge there. The cavity 4 is C1. It is withstanding all pump pressure when we turn left. To do this, under its edge, a stamped supporting holder is placed (in the image of brown). If this holder is not, the gland will turn out. And if it is, the edge of the gland will soon be cut into its sharp edge. When exhausting the gland, the holder will deteriorate. In a small repair kit it is not. Instead of rubber gland, it was more appropriate to put the same ring as in other places.

Further, K1 and K2 rings are made cryingly illiterately (I apologize to the developers), this is also a sore place. All rings in Gure work on the principle of cuff in brake cylinders. The main role is played by a rubber ring, which is fond of oil and under the action of its pressure "plugs" the slot between the ring and the wall of the groove, automatically pressing the ring to the shaft (or to the cylinder). The fluoroplastic ring for this should be cut (like all other rings). But these two rings are whole from a rigid collest. They are not amenable to the action of a rubber ring and practically do not work as it should. In addition, these rubber rings are put on with tension, fall on the bottom and do not participate in the process at all. Both of these rings are the "left" working cavity (i.e. the cavity on one side of the piston, which is filled under pressure when turning to the left). Cushkin's gland also isolates the "left" working cavity. When leaks through rings become big, GUR stops helping to the left. The "right" working cavity is devoid of such leaks at all.

Going on. And who thought it was and for what reason, to put both radial bearing only on one side of the Tshaka shaft?! Bearing shortage? The sump in the place of the aforementioned rings rubs the metal for metal under the heavy load. The hole splits, it becomes oval and the normal work of the rings can not go. The most interesting thing is that nothing bothers to eliminate the above leaks at all. Why put rings if you have a deaf cover enough to withstand all the pressure? At least a couple of drain areas (2 and 3) can be reduced. To do this, shut down the channels inside both shafts, cut the thread and screw the technological channels (instead of balls), and on the adjusting bolt to screw the deaf nut so that the threads do not fry. The cavity 1 will have to connect to the plum to another. Practice shows that the glands do not guarantee complete tightness under the operating pressure.

Using your events, I manage to increase the resource of the gur of three - four times.

P. S. To compensate for leaks, designers configured the flow valve for increased consumption. If you reduce leakage and reduce pump consumption, you can reduce the pending. To completely get rid of the sieps, it is impossible to change the design of the spool.