Bathhouse in the country (45 photos): design and choice of location. Construction of a bath from timber, bricks or blocks. Do-it-yourself bath in the country: project, materials and guide, how to build a bath Arrangement of a wooden bath inside

The quality of the interior decoration in the bath is not only in the attractive design and pleasant aroma, but also in the practicality of the structure itself. In a Russian bath, the temperature of humid air sometimes reaches +120 degrees, so the correct facing of the steam room can not only protect the walls from the aggressive effects of steam, but also protect a person from burns and allergic reactions.

Peculiarities

Many home craftsmen are sure that all work on finishing the steam room from the inside comes down exclusively to the stylish decoration of the walls, floor and ceiling. This is a common misconception; in practice, the organization of many other processes is required: hydro and vapor barrier, insulation of ceilings, engineering communications, treatment of coatings with antiseptics, fungicides, antiprenes and much more.

The temperature in a traditional Russian bath, as a rule, ranges from +80 to +120 degrees, and the humidity level is over 30%. Such operating conditions are considered extreme for any finishing materials. That is why, in the interior arrangement of such premises, only the strongest and most environmentally friendly materials are used that do not emit toxic substances and do not spread any unpleasant odors.

Only such raw materials are suitable for finishing, which heats up to a maximum of + 50-60 degrees, only ceramics and wood meet this requirement. The place near the firebox, like the stove itself, as well as places that can come into contact with human skin, are lined only with natural materials with a low level of resinousness. Therefore, coniferous varieties of wood are only suitable for finishing auxiliary rooms.... Otherwise, there is a high probability of burns and the development of airway spasm, which leads to a sharp deterioration in well-being.

Wood must be treated with fungicides, as well as solutions that increase its hygroscopicity - this is necessary to protect the coating from the damaging effects of moisture and prevent the appearance of mold and mildew.

Materials (edit)

Many people wonder what material is better to decorate the premises inside the bath. The most widely used lining is small panels used for cladding vertical surfaces. It is made from different types of wood. The main advantages of the lining are as follows:

- prevents the formation of condensation;

- is "breathable" material that does not impede air circulation;

- has an aesthetic decorative appearance;

- easy to install;

- differs in a relatively low price.

For finishing inside the premises of the bathhouse, finishing with an unedged board is allowed.

- African oak (abachi). It differs in lightness, but at the same time strength and increased strength, it is lightweight, does not emit resin and contains practically no knots. Abachi finishing materials do not burn the skin. However, this is a very expensive material, so not everyone can afford such a cladding.

- Cedar... The Ussuri and Altai breeds are most often used in decoration. They are resistant to high temperatures and excessive humidity, and they are also an environment in which fungi and mold do not grow. At the same time, wood has an aesthetic appearance and exudes a pleasant aroma.

Cedar is widely used in medicine, where it is famous for its medicinal properties due to its calming and anti-inflammatory effects on the human body.

African oak

African oak

Cedar

Cedar

- Linden... Baths are often lined with linden croaker. Its advantages include high strength and strength with a relatively light weight. The tree of this variety tolerates temperature fluctuations and frequent exposure to moisture, has an interesting texture and gives off a healing scent that has a healing effect on people suffering from diseases of the respiratory system.

- Alder. This is the optimal material for the interior decoration of the bath, it is pleasant for the skin, and besides, when heated, it changes color a little, and after cooling down, it returns to the original one. This interesting effect creates additional aesthetic pleasure and enhances comfort when taking bath procedures. From a practical point of view, it is worth noting that alder does not emit tar and contains very few knots.

Linden croaker

Linden croaker

Alder

Alder

- Larch... This tree belongs to pine, it is distinguished by its strength and pleasant texture. When heated, it emits a pleasant aroma, as well as phytoncides that are beneficial to health and microclimate. Larch can serve for quite a long time.

- Aspen. This material has a low cost, therefore it belongs to the most budgetary options. The advantages include zero resinousness and ease of processing, however, this coating is prone to a variety of fungal diseases.

- Birch. It has a homogeneous strong structure and an attractive appearance, but it may deform slightly under conditions of high temperatures. In order to prevent this from happening, when buying, you should give preference to carefully dried materials.

- Ash. This is a very beautiful type of wood that can be used to achieve a stylish decorative effect.

Species such as Meranti, Sedrella and Ofram are very good for decorating baths - these are expensive types of wood. Their main difference is that even when exposed to high temperatures, they maintain a temperature equal to that of the human body. Therefore, they are very easy to use. However, their cost is quite high.

Not all wood is good for interior lining of baths. For example, pine and spruce can only be used to decorate the shower room and recreation area. Making them in the steam room is not allowed, since the material at elevated temperatures emits resins, which, in contact with the skin, can burn it.

Not only walls, but also floors are faced with wood. However, ceramic tiles can also be used to decorate the latter, and the place where the firebox is equipped is faced with brick. Perlite is used directly under the floor covering - it is sand with good thermal insulation properties. This material is very light, so it is optimal for use in closed rooms where there is no wind, otherwise it will swell.

The materials that are taken for the cladding of the steam room should not contain any knots, protruding metal parts should not be mounted - all handles and holders are made only of wood. Even the shelves are made without the use of nails, since any metal object under high temperature conditions is very hot and can cause burns. Some consumers finish baths with clay, brickwork, salt tiles, bast and stone.

It is necessary to dwell separately on materials that cannot be used in the decoration of the bath, especially around the stove. Fiberboard and particleboard are flammable products that also absorb moisture well. The only place where their use is permissible is in the dressing room.

Regardless of the material used, do not cover them with varnishes and enamels, as well as stain and other organic compounds. Under the influence of high temperatures, they begin to release harmful substances that can lead to general intoxication of the body.

Step-by-step finishing instructions

The interior decoration of the bath includes several technological processes, each of which helps to protect the building from the aggressive effects of hot steam and forms a favorable microclimate in the sauna. At the same time, absolutely all work can be done by hand without the involvement of specialists.

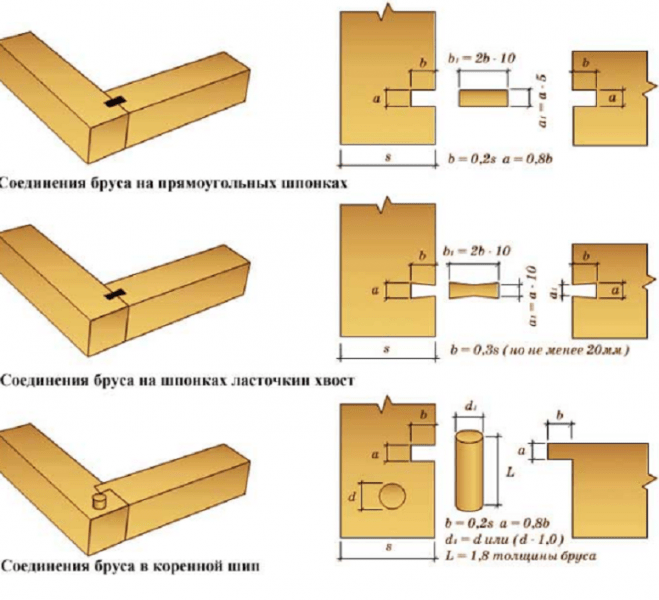

To begin with, the premises must be insulated and a vapor barrier installed in them. For this, basalt wool is widely used, which is distinguished by good thermal insulation, and foil, which prevents the accumulation of condensate. The sequence of actions and work steps are standard.

Ceiling insulation

You can start work with finishing the ceiling. At the first stage of the internal arrangement of the bath, its thermal insulation is carried out. To do this, a foil film is fixed on it with the reflective side down, while the coating is overlapped, and the joints are insulated with aluminum tape. The lathing is mounted from wooden blocks, for which screws are used to fix it. It serves as a frame for the finishing cladding of the steam room.

By the way, do not forget to protect the floors from the attic side. Before filling in a layer of insulation there, you should take care of laying a plastic film that will not let dust and debris inside the bathhouse.

Thermal insulation of walls

The principle of wall insulation in the bath is the same as that of the ceiling. The only difference is that before insulating the walls, it is necessary to carefully cover up all kinds of cracks and joints, only after that you can proceed directly to the installation. The thermal insulation material is mounted from bottom to top, perpendicular to the floor in three layers.

The first layer is waterproofing, which is applied to prevent condensation from settling on the walls. The second is the insulation itself, which helps to maintain the required temperature regime. Vapor barrier is needed to effectively protect the thermal insulation material from moisture.

Floor insulation

The most practical and durable is the floor made of concrete. However, this coating is quite cold, which leads to discomfort in the steam room. That is why most consumers prefer wood for finishing the floor in the bath. To begin with, a foundation is being set up, on which beams and logs are laid. The voids formed between them are filled with insulation, as a rule, a layer of sand or expanded clay is applied for this. Some insulate with sawdust, but this material will not last long in conditions of high humidity.

Then the vapor barrier and the "first floor" are traditionally applied, a heater, a layer of waterproofing is laid on top, and only then the base "finishing" floor. The first floor is a coating made of concrete and crushed stone, it is applied in a layer of 10-15 cm. To ensure effective waterproofing, roofing material is used, and mineral wool or expanded clay should be preferred as insulation. The finishing floor is equipped with a lining so that it will serve for a long time, it is treated with special antiseptic solutions.

The guide to finishing the bath has its own nuances. As already mentioned, clapboard is considered the best option for facing steam rooms and washing rooms; it looks stylish and aesthetically pleasing in any interior. You can make it yourself, however, the modern market offers a wide selection of products from any wood, so everyone can choose a ready-made coating to their taste and wallet. The main advantage of the lining is ease of installation. To fix it on the wall, it is enough to use simple nails without heads or clamps.

The floor, ceiling and walls are finished in the same style. If the walls are lined with clapboard, then it is better to mount the ceiling from the same material. Fasten it with a small gap, which avoids deformation in the event of swelling of the coating.

Such a gap protects against the need to rework the entire coverage area. It allows the lining to move if the situation requires it.

As for the floor, it can be made of wood or ceramic tiles. Wood floors can be leaky or leakproof. In the first case, the boards are mounted on logs with a gap, which, as a rule, is 5–20 mm. Boards of non-leakage coating are stacked tightly to each other, therefore, grooved material should be taken for them.

If the choice has settled on clay tiles, then keep in mind that after the steam room it is not very comfortable to step on such a surface. In addition, it can slip easily. That is why experts recommend laying on top of the tiles a wooden flooring made in the form of a narrow lathing or using a cork covering. The tile is laid on a pre-leveled surface on a special glue, and all seams are treated with a sealant or grout of a suitable color.

Separately, I would like to draw attention to the processing of lining and other materials that are used for interior decoration of baths. In order for the cladding to serve for many years, does not lose its aesthetic appearance, does not crack and does not become covered with fungus, it is treated with special antiseptic compounds. The tree has a loose structure in which microbes like to "settle". If we neglect the processing, then rather fungi and mold will simply populate all the wood and destroy it.

Certain requirements are imposed on impregnations: they must protect the raw material, however, they must not interfere with it "breathing". In addition, the material must be made from environmentally friendly components that do not emit toxic substances at elevated temperatures. In addition, the coatings that cover the shelves, benches and table must be able to withstand regular wet cleaning.

The shelves are additionally treated with deep absorption solutions. They are available in the form of gels, solutions and sprays.

Room design options

The design concept of bath interior decoration can embody ideas of a wide variety of styles. The most common is Russian classical. This is ideal for decorating a wood-burning bath. Its main advantage lies in the fact that such a decor does not require large expenses and can be easily equipped with your own hands.

The main components are wooden walls, a plank floor, laconic benches and always a large wooden hospitable table. This interior is complemented by a Russian embroidered tablecloth and all sorts of little things in the Russian folk style (wooden dishes, brooms on the walls and other elements). Such a bathhouse will always be cozy and comfortable.

Country style is very close to Russian design. This is also a model of a "village" bath, but with national motives of other countries. Light wood-burning furniture, usually skillfully aged, dishes depicting rural landscapes and bright textiles are the main features of country-style design that any bath owner can do.

Lovers of the East can be recommended to bring the features of a hamam into their Russian steam room. From the point of view of decor, the main feature of the Turkish bath is considered to be a mosaic, which is used in this country for facing all rooms or a room with a pool, because it is there that such a design will come in handy. In addition, the relaxation room can be converted into a hookah bar, a low table can be placed and pillows in bright colors are scattered around.

The fashionable Scandinavian style has made its way to the baths. This is not surprising, because the main feature of this trend is simplicity and natural chic. Deliberate rudeness is combined with a classic design, and all decor elements are simple and functional. The rest room can be decorated in a Scandinavian style. To do this, the surface is plastered with light shades and a couple of bright accents are created, for example, a lamp of saturated color or unusual paintings on the walls.

Classic elements can be brought into the washroom design. If you build several arches, decorate the ceiling with stucco or install a multi-level floor.

The Art Nouveau style is less common in the interior of bath rooms. It assumes an abundance of curved lines, abstract images and vibrant colors. This is a solution for those who do not like stereotypes and are not afraid to experiment. Most often this design is used in saunas made of foam blocks.

Steam room

The steam room is considered a fundamental element of any bath, so only the highest quality materials should be used for its decoration. At the same time, as a rule, it has small dimensions, so the internal layout must be carefully thought out in such a way that there is enough space for everyone, as well as for all the necessary shelves and sun beds.

We should also focus on lighting. Usually, small lamps are mounted in the ceiling, which will give a dim, subdued light. A good visual effect is achieved by equipping semicircular ceilings and combining them with oval-shaped loungers and benches.

Shower room

The washing room is characterized by high humidity, which makes its own demands on the materials used for cladding. It is good to use softwood. Any kind of synthetic flooring is strictly prohibited for finishing the washing room. This room is constantly cleaned, so it is more practical to use tiles in the design, because it is easy to clean and allows you to depict any ornament on the walls. In addition, the tile looks spectacular with other facing materials.

The steam room in the bath is the main room. It is in it that the stove, sun beds and other interior details are located, which are necessary for the correct organization of the procedure for receiving procedures.

That is why the question of how to equip a bathhouse inside should be considered separately, paying attention to even the smallest details.

Steam room interior decoration

First of all, it should be noted that when arranging all objects, one should focus not on design qualities and beauty, but on functionality and convenience. Fire safety considerations should also be followed to prevent fire.

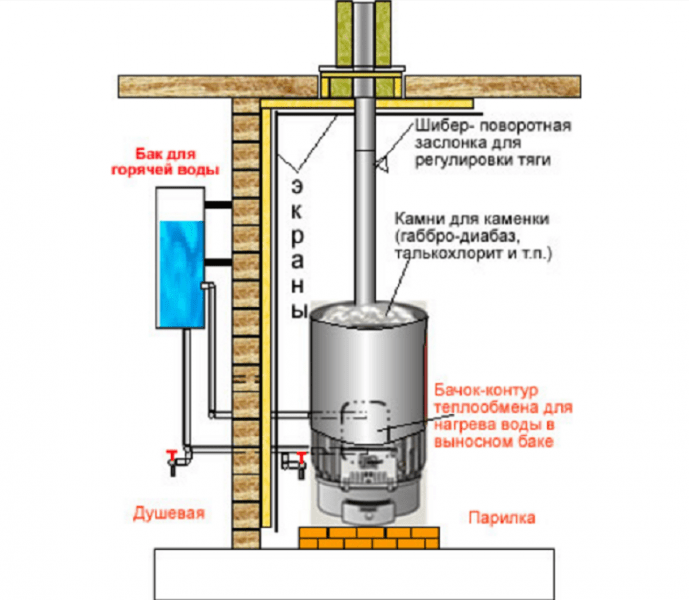

Bake

- This device is the main one in this room. It is it that creates and maintains the required temperature, which means that special attention is paid to its installation.

- First of all, it must be said that the seat for the furnace must be made at the stage of making the foundation. This is due to the fact that the device requires a solid and reliable base.

- The standard arrangement of the steam room of the bath assumes that the stove will be located in the corner farthest from the entrance door. This is necessary in order to reduce heat loss when visiting the room.

- At the same time, professional craftsmen advise to immediately install protective screens. Their function is to protect wooden surfaces from infrared radiation.

- Such a screen is made of brick or natural stone. However, professional bath attendants advise using factory-made products with a reflective surface that will redirect radiation to the center of the room, increasing the heating level.

- If the design of the stove for the bath assumes the presence of a water tank, then it should be installed in such a way that the container is easily accessible.

- Considering all these features, the internal arrangement of the steam room begins with the oven.

Advice!

Quite often, factory products are sold along with protective screens and detailed instructions for a quality installation.

These instructions must be followed carefully as they were designed specifically for these models.

Warming

- This type of work can also be attributed to the arrangement. This is due to the fact that it is thanks to him that you can reduce energy consumption for heating and increase the thermal capacity of the room.

- To decorate the walls and ceiling of the bathhouse, wooden materials are used, which are usually fixed on the crate. This makes it possible to install almost any insulation.

- In order for the room to retain heat well, the installation instructions recommend using a material that has a layer with a reflective surface. Thanks to it, infrared radiation is redirected into the room, which makes it possible to increase the heating level.

- It is worth noting that special adhesive tape with the same reflective surface should be used to organize the joints. As a result, the insulation must create a complete seal.

Interior items

- When creating a steam room with your own hands, you need to correctly think over the location of all interior items. This is especially important if the room is small.

- Considering that the stove is installed at a certain distance from the bath door, a lounger with multi-level shelves should be placed on the opposite wall.

- Some craftsmen prefer to make two or three levels of shelves in the steam room. This will save space and at the same time make it possible to get a complete and functional interior.

- When creating sun loungers and shelves, it is necessary to focus on the personal preferences of users and their dimensions. However, it is worth remembering that there are standard solutions that have proven their effectiveness in a year of use and they can always be adapted to specific technical conditions.

- Many bath attendants strongly advise installing a special thermometer in the room. Its price is not very high, but it is thanks to it that you can control the heating level.

- This device should be mounted next to the front door. This place can be considered the coldest and all indications should be taken with this feature in mind.

Conclusion

In the video presented in this article, you will find additional information on this topic. Also, based on the test, which is set out above, it can be understood that the arrangement of a steam room in a bath requires strict adherence to all instructions in order to get an interior with maximum functionality, which is very important for this room.

The article will be useful to those who plan to independently carry out the interior decoration of the bath rooms. Detailed step-by-step instructions with a photo will help to produce cladding and cladding with high quality and in compliance with construction technologies.

Features of finishing bath rooms

In a classic Russian bath, there must be such rooms as:

- steam room;

- washing;

- vestibule (changing room).

If the area allows, modern buildings will equip a separate recreation room, billiard room, pool, veranda, barbecue area and even a full kitchen.

Despite the fashion trends, the basic requirements for the bath remain unchanged:

- in the steam room, persistent hot steam is needed,

- in the washing room - non-slip floors and the possibility of convenient bathing procedures,

- in general, the premises have a comfortable microclimate and aesthetically pleasing environment.

The functionality of the bathrooms depends a lot on the correct finishing. Even if your structure is built of rounded logs, and the walls look beautiful and aesthetically pleasing from the inside, it is recommended to make the interior decoration of the bath, as this will significantly extend its service life.

Each room has a number of features that must be taken into account when choosing materials and cladding methods.

Steam room

When decorating the steam room, the following nuances must be taken into account:

- sharp temperature drops, the upper limit of which can reach 120˚С;

- the presence of hot steam emitted by a powerful and concentrated stream;

- high humidity.

A universal cladding option for a steam room is a cladding board, which should have the following properties:

- do not absorb moisture;

- have a low heat capacity, therefore, do not heat up from high temperatures and contribute to the rapid heating of the steam room;

- have a pleasant color and smell, while not emitting resin when heated;

- protect walls from rot and mold, help purify the air.

Of all the variety of lining, panels made of linden, aspen, cedar or African abasha wood are suitable for use in a steam room. When choosing a cladding material, pay attention to the quality of the wood - well dried and hewn, without knots and notches on the surface, it will reliably serve for many years.

The lining in the steam room is not treated with varnish, paint or antiseptic. These substances are toxic and, when heated, can negate all the benefits of bath procedures.

Before sheathing, the walls and ceiling are insulated. The cheapest material for these purposes is mineral wool, it is it that is most often used in decoration. Often, such insulation is used as basalt wool. It is more durable, as it is not subject to deterioration from the influence of high temperatures. However, cork agglomerate is considered the best insulation for baths. It is anti-allergenic, not subject to rotting, burning and the appearance of fungus.

The floor in the steam room is made warm, not slippery and pleasant to walk with bare feet.

Video - Interior of the steam room

Washing room

In the washing department, they usually not only rinse the body, but here you can relax after a hot steam room, have a relaxing massage, apply products for face, body or hair care. The convenience of the premises for carrying out various procedures must be taken care of already at the stage of construction and subsequent finishing.

The lining of the sink is done either with ceramic tiles or wood. Moreover, if deciduous varieties of lining were used in the steam room, then in the washing room preference is given to conifers - larch, spruce or pine. The resin they contain is moisture-repellent and protects materials from decay.

Particular attention is paid to the floor, it should not be slippery or cold. It is preferable to fill the base in the washing room with concrete, on which the tiles are laid out. Although a wooden floor is also possible.

To prevent slipping on a wet surface, it is recommended to make a flooring on the tiles in the form of removable wooden logs. They should be dried after completing the bath procedures.

Tambour, changing room, recreation room

Along with the washing room and the steam room, the rest of the bath rooms retains high air humidity. Here you can use both hardwood and softwood for decoration. The following materials are also used:

A combination of various types of finishes is common in such rooms, for example, wooden lining, tiles and natural stone.

Video - Relaxation room in the bath

Ceiling decoration in the bath

During operation, the ceiling is exposed to aggressive effects of hot steam and high humidity. It is important to protect the ceilings with steam and heat insulation to prevent damage to materials. For these purposes, aluminum foil or a building membrane is often used. They are equally effective at ensuring their tightness.

For vapor barrier, do not use foil with glued cotton wool. It is much thinner and less convenient for cladding work. Also, do not use foil with glued polypropylene foam. It is toxic when heated and therefore unacceptable for use in bathrooms.

It is important to carefully glue all joints with aluminum tape. If in the process of attaching the material you accidentally damaged it, immediately glue this place, then you can forget to do this and the vapor barrier will be broken.

In the steam room, you need to lay out a hole for the pipe. It is equipped with a box made of thin stainless steel sheet, which is filled with expanded clay.

The ceiling above the stove is additionally insulated with a steel sheet that protects the wood from excessive heat.

Step-by-step instructions for installing lining on the ceiling

Step 1. Slats with a cross section of 2 * 4 cm are sewn onto the ceiling with a lathing pitch of 40-45 cm. At the points of attachment of the frame, it is necessary to provide for ventilation gaps of at least 10 mm.

Step 2... The slats are placed horizontally on the walls, the direction is perpendicular to the lining.

Step 3. From one of the walls, wood panels begin to be fastened. The groove of the first plank is directed outward and the spike of the next is hammered into it. It is possible, and vice versa, there is no fundamental difference.

On a note! When installing, use pads and a mallet, this will avoid damage to the material.

Step 4. The strips can be fixed with special clamps, they are attached to the rail with nails or screws. But the easiest and most convenient way is to use a construction stapler. It reliably fixes the lining and significantly reduces the installation time.

Step 5. On the sides, gaps are left from the walls in the amount of 2-2.5 cm. This provides additional ventilation and prevents deformation of the finishing material. The gaps are subsequently hidden by the skirting board.

The first and final panels are nailed with small studs. They are driven in at an angle, the head is completely driven into the wood with a doboiner.

It is important to monitor the verticality of the planks, which is checked after installing each panel using a level. A simple building meter can be used instead. In this case, you measure the distance from the wall to the edge of the installed panels on one side and the other.

If there is a discrepancy in measurements, the lining is neatly knocked out to the desired level. For this, a small piece of the same panel is used, which is inserted into the groove and a mallet (or a hammer).

The panels are trimmed in the following way: they fix a wooden plate, under which a sharpened chip is carefully hammered.

The walls in the steam room are trimmed with wood. In the rest of the rooms, you can use tiles or stone.

Wall decoration with clapboard

The basic technique for installing wood panels on walls is no different from fixing them to the ceiling.

Step 1. We fill a thick bar horizontally along the entire perimeter - every 80-100 cm.

Step 2. We install mineral wool insulation. We cut the insulation to the required size with a sharp knife. We put it between the bars without tamping.

Step 3. We lay a vapor barrier, carefully glue all joints with aluminum tape.

Note! Carefully monitor the quality insulation in the corners.

Step 4. To provide a ventilation gap, we fill in the distance rail. The cladding is always performed at an angle of 90 degrees to the lining strips. Thus, if you plan to arrange the panels vertically, the lathing is nailed horizontally.

First, frame vertical slats are installed at the corners of the wall, the accuracy of their fastening is controlled by a plumb line. For an even placement of the horizontal slats, you can pull the cords at the top and bottom of the frame slats, that is, at the floor and above the ceiling.

The next rail is packed after 40-50 cm, and further along the perimeter, with the same pitch, the rest of the bars are attached. Always check the levelness of the installation with a level or plumb line.

Step 5. Doors and windows are enclosed in separate bars.

Step 6... We proceed to fastening the panels.

When cladding walls in bath rooms, it is recommended to fasten the lining vertically, starting from one of the corners. This will ensure a quick drainage of moisture to the floor, without retaining it in the grooves of the panels.

If you decide to do a horizontal finish, then lay the boards with the spike upwards so that moisture does not accumulate in the grooves. With this option, the boards are fastened from the ceiling, and not from the floor. The lathing is nailed vertically.

Wooden panels are fastened with clamps, ordinary nails, or a construction stapler. When using nails or self-tapping screws, they should be inserted at an angle of 45 degrees, the cap is completely sunk into the wood.

Be sure to leave 2-3 cm gaps when attaching the lining from the ceiling and floor for ventilation.

Often the lining has to be cut. For these purposes, use a saw with fine teeth or an electric jigsaw.

Before attaching the last rail, it is trimmed to the desired size and attached to the crate. On the first panel of the next wall, a ridge is cut off and installed end-to-end against the last rail of the first wall. Corner trimming requires special precision. The main thing here is to determine the required angle and draw a cut line before sawing. Adjacent corners of the panels must adjoin joint to joint, without gaps.

Video - Decorating the bath with clapboard

Insulating the oven from the wall

Special attention should be paid to the insulation of the stove from the wall. For these purposes, you can use one of the following options:

- stainless steel - attached directly to the wall behind the oven;

- minerite - heat-resistant plates made in Finland, consisting of cement, mineral fillers and reinforcing fibers. Mounted on 2 sheets if the oven is located in the immediate vicinity of the wall. When the stove is more than 40 cm away, one sheet of minerite is sufficient .;

- heat-resistant tiles made of kaolin clay, for example, from the Russian company Terracott;

- profile iron - the most budgetary option for insulation;

- red solid brick - laid out between the wall and the stove to the base of the pipe. If desired, you can isolate the entire space to the ceiling.

Wall cladding with tiles

Quite often the walls in the washing department or in the rest rooms are finished with moisture-resistant ceramic tiles. It is made from environmentally friendly, non-toxic materials that are safe for health when heated, do not absorb moisture and give a beautiful and modern look to the room.

Step-by-step instructions for laying tiles on the walls in a bath include a preparatory stage and cladding.

1) Preparation

If the walls are brick or cinder block, then they are cleaned of dirt and dust, coarse plaster is performed, and irregularities are leveled with a solution.

Wooden walls are covered with waterproofing material - roofing felt or tar paper. It is nailed down with a construction stapler, and a fine mesh-netting is sewn on top. Finish the preparatory work by applying a cement mortar that completely covers the metal mesh.

A perfectly flat wooden beam is nailed at the floor level, from which the finishing will begin. You can use a metal UD profile, which is fixed along the level along the wall.

To control vertical rows, a conventional plumb line or laser level is used.

2) Laying tiles

To fix the tiles, you can use both a self-prepared solution of cement and sand (in a ratio of 1/5), and ready-made glue. It is more convenient to use industrial glue intended for baths; it withstands large temperature drops and high humidity well.

Before starting work, the tile is immersed in a container with water and left until all the air is released from it. This will provide better adhesion to the mortar.

The cladding is started from the bottom, from the attached level.

It is important to lay out the first row ideally evenly, since the quality of all subsequent cladding will depend on it.

Using a notched trowel, the adhesive is applied to the back of the tile or directly to the wall. The tile is pressed against the wall, while the glue should slightly protrude beyond its edges. To get the square perfectly straight, adjust it with a rubber mallet.

Pay attention to the gap between the rows of tiles, it should be the same along the entire length and height. To do this, when adjacent rows are laid out, plastic crosses are installed in the corners of the tile in the gap.

After 2 days, the glue is completely dry and the level can be removed.

The gaps between the rows are filled with grout, which matches the color of the cladding. It dries for 11-12 hours.

The final step is to clean the walls from the remnants of grout and other contaminants. The tiles are thoroughly washed and wiped dry.

Tiles create a lot of room for creative expression. It can be laid out in even rows, offset or diagonally. For beginners, the easiest and fastest option is recommended, when the squares are located exactly one above the other.

The runaway pattern looks like this.

Stacking tiles

Diagonal cladding.

To create complex combinations of tiles of different colors, it is recommended that you first lay out the drawing on the floor, then outline the diagram on the wall, and only then proceed with the decoration.

Video - The principle of laying tiles

Wall cladding with terracotta flagstone

Heat-resistant terracotta tiles are a popular solution in bath rooms. It is moisture resistant and durable, withstands high temperatures and allows you to create an original and beautiful wall design.

The technology of its laying is somewhat different from cladding with ordinary thin ceramic tiles. Terracotta is a heavier material and requires special glue or mastic.

Below are step-by-step instructions for cladding with terracotta flagstone.

- Apply mastic to the flagstone in a thick thick layer. More glue is required than with lighter tiles.

- Press it against the wall and align.

- We install the rest of the plates.

- For even joints, we lay pieces of drywall between the plates.

- When laying parallel rows, do not forget to check the horizon with a level.

- Grouting can be done after 10 hours. For this we use a special wide-joint heat-resistant grout. We dilute it with water and beat it with a construction mixer until a homogeneous consistency. A properly prepared mass resembles thick sour cream.

- We release the structure from plasterboard squares.

- We fill the construction gun with grout. Cut off the nozzle of the gun at an angle of 60 degrees, the hole should be 8-10 mm.

- Fill the gaps between the plates with grout. The squeezed out mass should not go beyond the level of the cladding, and also fall on the front side of the slabs.

Be careful when handling the gun. If the mastic does get on the decorative surface, do not try to wipe it off right away. Wait 2 hours, then scrape off the dried composition without rubbing it.

- The grout is distributed along the joint in any direction convenient for you. You can first walk along the horizontal joints, then along the vertical ones, or vice versa.

- After 2 hours, we proceed to decorative jointing. This will give a finished, finished look to the cladding.

- For jointing, you can use a simple screwdriver with a working surface width of 7-8 mm or a rigid wire ring.

- Finally, put on clean gloves and run your index finger along all the seams.

Video - Terracotta tiles in the bath

Bath floor decoration

If the floor is made of wood, then it does not require any additional finishing.

Begin cladding from the corner. Unlike wall decoration, a perfect horizon is not created on the floor, i.e. the tile is located at a slight slope towards the drain hole.

Before applying the mortar, mark the location of the squares on the floor using a level.

It takes a lot of time and effort to independently finish a bath. It is required to solve a number of important problems - what material to choose, how to attach it correctly, how to ensure safety during operation and create a cozy and harmonious atmosphere in the premises. The recommendations and step-by-step instructions given in the article will help you cope with the task at hand and, after completing all the work, enjoy a good and complete rest during bath procedures.

Video - How to put tiles on a wooden floor in a bath

Bath design inside

Cozy and high-quality finishing of the bath inside is the dream of almost any Russian person who knows a lot about this business. And for such a pleasure, one does not spare either the means or the time. In order for the interior decoration of the bath to be done with high quality, before starting work, it is important to know the basic rules of decoration, because the bath is being built not for beauty, but primarily for health, in order to fully feel the effect of a hot broom on the body person.

If we are talking about a Russian bath, then the material from which the structure itself is built does not matter - the steam room must be made exclusively of wood. This is required by traditions, covenants, and so to speak - "Russian spirit". It is possible to substantiate the given by the following scientific facts:

Wood is one of the most environmentally friendly materials; it is the most pleasant and useful for humans;

Wood has low thermal conductivity, as a result of which the probability of getting burned is extremely small;

However, the tree is characterized by the ability to evenly distribute heat over its full volume, which affects the heating rate of the steam room;

If the wood, for interior decoration, was processed correctly, there is a continuous air exchange - and then the bath does not require additional ventilation, if it is, of course, built entirely from a dever;

The tree, when the temperature rises, releases substances that affect the health and relaxation of a person;

And in general, the very texture of the tree is already an ornament, and no additional coloring is required.

Bath interior inside photo:

The choice of materials for the interior decoration of the bath.

One of the main stages of internal work can rightfully be considered the choice of finishing material. Its quality must meet the following criteria:

Be resistant to hot air, water ingress and increased air humidity.

Be hygienic.

Completely free from toxins that could be released during heat.

Must not cause allergies or burns by contact with human skin!

Be strong and durable.

Be decorative and pleasing to the eye with your flowers.

It is believed that both to build a Russian bathhouse and to decorate it entirely from wood: the smell of fresh wood, together with the scent of birch brooms, merge and give an atmosphere of comfort and bliss.

Important: special attention should be paid when finishing the sink.

Since coniferous materials are absolutely not suitable for decorating a steam room (besides, as you know, pine trees get very hot, and it may not be very pleasant to touch it during procedures), they are completely suitable for a rest room and a dressing room. The temperature in them is not so high that the needles would begin to release resin, but its aroma will not only delight your soul, but also bring a healing effect to the body. In principle, a variety of materials can be used in the washing room: drywall, river pebbles, PVC, moisture resistant fiberboard. But, of course, it will be more expedient to use tiles. Considering the fact that the tile becomes very slippery when water gets on it, it is recommended to cover the floor with a wooden grill, which could be dried at any time after taking water procedures.

Steam room decoration

If we are talking about a real Russian steam bath, with its heat and steam, then by tradition, its interior decoration is made only of hardwood (birch, aspen, poplar, linden, etc.).

Attention: Ash has a very beautiful decorative effect - a beautiful core. Bath attendants love this material for its beauty, strength, durability and durability. Also, one can note an exotic but very expensive material such as African abashi oak. Many connoisseurs of paired traditions, in order to maintain their reputation, are willing to pay even less money.

The original breed to which we are accustomed is linden. Its honey scent adds even more coziness to the steam room. Nevertheless, aspen is resistant to high humidity and therefore does not rot.

Deciduous trees have the main feature - they are weakly prone to splitting and rotting, they do not heat up to a state in which they can be burned. The use of pine, despite the cheapness of this material, is excluded, due to its property of releasing resin at high temperatures. Also, do not consider oak - when heated, it becomes very slippery, which can lead to unwanted injuries, and we came for pleasure. If in the dressing room, for finishing work, it is allowed to work with unnatural materials, then the steam room must be made only of wood, as well as handles and doors.

The floor of the steam bath is made both with the use of sanded boards and covered with tiles. The finishing of the place where the stove will be installed must be made of non-combustible materials - brick, tile.

Important: in order to keep the hot air well inside, the floor in the steam room should be about 10 - 20 cm. above the pre-bath floor. Laying the boards on the logs, I do it as tightly as possible to each other, and are fastened with self-tapping screws on wood. In the steam room, for finishing the floor, it is still recommended to use tiles. Because whatever one may say, and over time, moisture spoils the boards. In the same way as in the washing room, a wooden grate or shield should be placed on the floor in the steam room to prevent injuries on the wet floor.

Shelves and benches

An obligatory advantage of a good steam room is its comfortable, well-reinforced, non-creaky and non-wobbly shelves and sun loungers. The shelves can be mounted in two, ato and three tiers.

Important: for a comfortable seating, the location of the upper shelf under the ceiling should not be less than one meter.

Shelves are required to be made in different sizes:

Lower - up to about 30cm;

Average - 60cm;

The upper one is in the area of 1m.

Important: An important part of finishing bathroom furniture is the impregnation of the sanded wood with special agents protecting against decay. These impregnations are carried out exclusively on the basis of organic components. Such means include wax or oil, as well as aqualak, which has recently become more and more popular. It was created with a specific task - impregnation of wood for finishing work in saunas, baths and similar premises. Penetrating deep into the material, these impregnations provide protection against moisture, high temperatures, all kinds of microorganisms and all that stuff. Naturally, the use of protection of such a plan, for its advantages, such as increasing the durability of the bath interior and furniture, steadily pulls and the disadvantages - a drop in the useful effect of wood. Be that as it may, benches (shelves) in any case need to be treated with such means to ensure maximum comfort when exposed parts of the body come into contact with a tree. Well, ceilings and walls do not need to be impregnated.

In addition, the edges of the benches should be rounded and the screws and nails deeply embedded in the wood. Also, an effective moment for ventilation and a long service life of the shelves is the way they are made in a lattice form.

We decorate the dressing room

Pine panels are the recommended material for finishing work in the dressing room. They heat up weakly, and do not emit any harmful resins. Under the influence of low temperatures on the panels, in the dressing room, there will be a pleasant, slightly perceptible coniferous smell. Before performing installation work with plates, the wall must be insulated. For this, it is recommended to use foam or mineral wool (as you know, these materials retain heat very well). The ceiling of the dressing room can also be finished with pine slabs, and the floor - well-fixed on the logs with polished boards.

Restroom

But the decoration of the bath inside does not end there. After all, we still need somewhere to rest, after such significant, albeit pleasant, stress on the body. During the planning of the bath, we certainly did not forget about the relaxation room. In principle, it can be finished with any desired materials, but it looks more aesthetically pleasing when its decoration is maintained in the general style of the entire interior of the bath.

Decorating a wooden bath inside

There are a number of rules to ensure the right microclimate and durability of your wooden bath:

The inside cladding should be done using vertical arrangement of boards, being very close to each other;

No need to paint them to exclude the release of harmful substances;

To avoid floor rotting soon, no need to insulate the floor, since moisture will constantly affect it;

Another secret of effective heat preservation is use of small windows in the bath;

To create a state of relaxation, in the bath they use dull lighting;

Russian bath, like interior of the Russian bath inside- this is not a simple bathhouse with a steam room, it is a folk tradition, its flavor, so to speak, in the decoration and interior decoration with wood.

We make saunas at home: we re-equip the room into a steam room ourselves

In the west, within the city limits, a bathhouse in the basement of a house has already become quite normal, because the land there is expensive, and it is enough only for the construction of a small house and a small plot of land.

According to statistics, in Finland, half of the residential buildings have a sauna. And if it is not in the apartment, then there must be a shared sauna in the basement of the house.

For the same reason, in order to save space, projects of such houses are being made in Russia. In this article, we will tell you the advantages and disadvantages of this option, and the technology for its construction.

Pros and cons of a home bath

Bath in the house for and against:

- The bath can be done in the house or separately as an extension. It is much more convenient and economical. You will save money on foundation, roof, walls, and communications. Do not take up extra space and effectively use the basement or basement room.

- Possibility to connect the underfloor heating circuit to the washing room from a common boiler.

- It is more difficult to drain water in the basement. To do this, you will need to make a depression in the floor (container) to collect water and pump it out from there with a drainage pump with a float into the general sewer.

- With a poor ventilation system in the bath, moisture will accumulate, mold and mildew will form.

- High humidity and fire hazard is created. Therefore, it will be necessary to install a forced ventilation system, air dryers in front of it and a fire system.

- If you build separate bath houses, you can use the second floor at the same time as the steam room, making it a guest house.

- Basically, the sauna inside the house is done with an electric stove, so wood-burning creates an increased fire hazard. Therefore, fans of the classic steam room may not like the option with dry steam from an electric oven. If you want to get a traditional Russian steam room, then it is better to build it separately together with a brick stove or think over a good hood.

Arrangement of a bath in the house

In this example, it will be described how a bathhouse was made in the basement of a private house, which causes additional difficulties with ventilation and water drainage.

Room insulation

As you already understood, remodeling a house will require special attention to heat and waterproofing issues, as well as arranging a good hood, especially if a wood stove is your choice.

- First of all, a frame is made of wood for cladding the walls and ceiling of the bath. The volume of the steam room itself must be made as small as possible in order to buy a stove of lower power. Therefore, they try to make the ceiling 190-210 cm high, and the dimensions of the steam room are convenient for the location of the recumbent shelf.

Note!

At the place where the shelves and the oven are attached, the frame must be reinforced with mortgages in advance.

- Walls and floors are insulated with 10 cm thick mineral wool, and on the ceiling a minimum thickness of 20 cm must be used. Two layers of insulation on the ceiling are laid in a perpendicular direction. The use of thermal insulation will allow the oven to be used with a much lower power, and the heat will not go outside.

- You can also use mineral wool with built-in waterproofing, for example ISOTEC KIM-AL or Isover KT 40-AL.

Note!

It is forbidden to use polystyrene and other combustible heaters for thermal insulation of the bath.

- After that, you need to carefully and tightly secure the vapor barrier made of thick polyethylene. It is attached to the frame with a stapler, the joints are coated with a special paste and glued with tape. If desired, polyethylene can be replaced with another vapor barrier, aluminum foil or heat-reflective insulation.

Steam room decoration

- Tiles are laid on the floor of the steam room, and the seams are rubbed. To make it easier to clean the floor, you can make a slatted floor with your own hands from polished blocks.

- Before fixing the sheathing over the film, slats are stuffed onto the walls and ceiling to create a ventilation gap.

- Then the lining of the bath is nailed from the lining of 10-12 mm. It is attached to pins every 25-30 cm, the hat is hidden by the next bar. Before installation, do not forget to keep the lining for at least a day in the same room so that it adapts to constant humidity.

- The photo shows a bathhouse in a brick house measuring 1.5 * 1.9 * 2.1 m with red cedar cladding. All joints must be covered with decorative molding.

- We mount the top and bottom shelves. For easy access to the space below, the bottom shelf can be made removable or sliding.

- For the installation of shelves, self-tapping screws with a special coating are used, which protects them from rust. To avoid accidentally hitting their hot hats, you need to drown them about half the board. For this, a drill with a milling cutter was used.

- Then we install a wooden or glass door and platbands, it should open outward. For beauty, we sheathe the wooden door inside with the same material as the walls. It should not have locks, and the handles should be made of wood.

Note!

The wiring is done before installing the cladding.

You can only use special wires that can withstand temperatures over 170 degrees.

- We install a waterproof and heat-resistant 12/24 V luminaire through a transformer and close it on top with a wooden grate.

Ventilation device

Ventilation can be done forcedly or naturally. To do this, you need to provide an air inlet under the oven or above it (see photo).

The hood is usually mounted as low as possible in relation to the oven so that it does not draw hot steam from above. Most often it is placed under the shelves.

An optional drying hole is installed above the door on the ceiling, which closes during heating and taking a sauna. It can also be dried by simply opening the door after use.

If it is not possible to put the hood in the steam room itself, a gap of 10-15 cm is left under the door, or an adjustable window is made at the bottom, and the hood takes place through ventilation in an adjacent room. A bath in the basement of a house is usually done with forced ventilation.

Furnace installation

All that remains is to install the stove and the sauna house will be ready for use.

- In this example, a 6 kW electric heater was used. The price for an electric heater of similar power starts from 7 thousand rubles.

- When installing, you must follow all the manufacturer's recommendations for indents from combustible materials, if necessary, make a thermal shield on the walls behind the oven. The oven must be connected to ground.

- The stove is mounted through the casing to the frame posts and to the floor using special fasteners from the kit.

- It is better to make a wooden fence around the stove so as not to accidentally fall and touch the hot walls.

- Electric heating elements are completely covered with stones. They should be large in size, and not very tightly packed, without effort.,

Chimney installation

If a home bath is made with a wood-burning stove, its pipe can go out both through the ceilings and the roof, and go straight up from the outside.

The main thing is to comply with all fire safety rules.

- For the chimney, sandwich pipes are used or ordinary stainless steel pipes are insulated.

- Insulation must be done indoors to increase traction and protect against fire. For insulation, 5 cm mineral wool with waterproofing is suitable.

- An open pipe should run 30 cm away from combustible materials, or 15 cm if it is thermally insulated.

- A condensate drain must be provided at the bottom of the chimney. The top of the pipe must be covered by a deflector to protect against backdraft and ignition from sparks.

- The place where the pipe passes through the wall / ceiling is closed with a metal nozzle of at least 30 * 30, and the voids are filled with non-combustible material, for example expanded clay.

Conclusion

Of course, it is best to plan the presence of a bath even at the stage of building a house, and think in advance about the optimal position of all communications. A good alternative to re-equipping the premises is to buy a ready-made booth, but such options will cost more than 100 thousand rubles.

Finally, you can watch the video in this article, which shows instructions on how to make a bath at home.

Having set out to build a bathhouse with your own hands, you should study in detail each stage of construction. A qualified approach when choosing a site, a competent project and adherence to recommendations at all stages of arranging a bath will ensure a worthy result of the work invested.

Rules for determining a place for construction

A skilfully selected construction site guarantees convenient operating conditions in the future. Experts recommend taking into account the following recommendations:

- Despite the benefits in terms of the consumption of building materials, the addition of a bath to the main dwelling creates an increased threat of fire.

- Avoid the close location of the reservoir - this can provoke flooding of the building.

- The back of the courtyard is the optimal place for the sauna.

- The construction of a bath is necessarily accompanied by the arrangement of communications, including a drainage system, and effective ventilation.

- Avoid areas near roads.

- To ensure maximum heating of the bath by the sun's rays, its construction on the southern side of the site will help. Protection against gusts of wind is an additional bonus of a winning solution when setting up.

- Building away from the contact line of the plots will help to eliminate disagreements with neighbors.

- In order not to provoke pollution of drinking water sources, a site for the construction of a bath is selected at a distance of about 20 m from a well or a well.

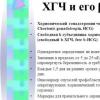

Any construction activity is not complete without preliminary planning. The bath drawings below will help you choose a suitable project.

The minimum dimensions of the building are determined based on the projected number of guests at the same time in the pair establishment. The acceptable area for one visitor is 5m 2 of the total bath space, a company of four will need 20 m 2. A standard bath includes the construction of a steam room, a dressing room and a washing room. If desired, the arrangement of other premises is also carried out. In order for the bathhouse to bring only positive emotions with your own hands, consider the following nuances when designing and building:

- The rational height of the rooms is from 2.0 to 2.2 m. Lower ceilings will create inconvenience for vacationers, a high room will require additional costs of heat carriers and increase the warm-up time.

- Arrangement of the exit of window openings to the west contributes to the extension of natural light. They usually take a steam bath at the end of the day, watching the sunset in between visits to the steam room is the best way to relax.

- It is better to plan doors on the south side, this will reduce the worries of clearing the entrance from snow.

Advice! The window and door openings of the baths are made small. The optimal dimensions of the doors are 70x180 cm, subject to the arrangement of a high threshold. Some of the inconveniences at entry are offset by the significant reduction in heat loss.

- The criteria for choosing materials for construction are their light weight along with their high energy-saving ability.

- The purchase of high-quality equipment and well-executed installation of communications contributes to the safe operating conditions of the bath.

- Avoid using resinous woods for decorating the interior of the bath.

After determining the optimal dimensions and other nuances of construction, proceed to the preparation of the following drawings:

- general bath project;

- plan of each room;

- option for arranging the foundation;

- roof erection scheme;

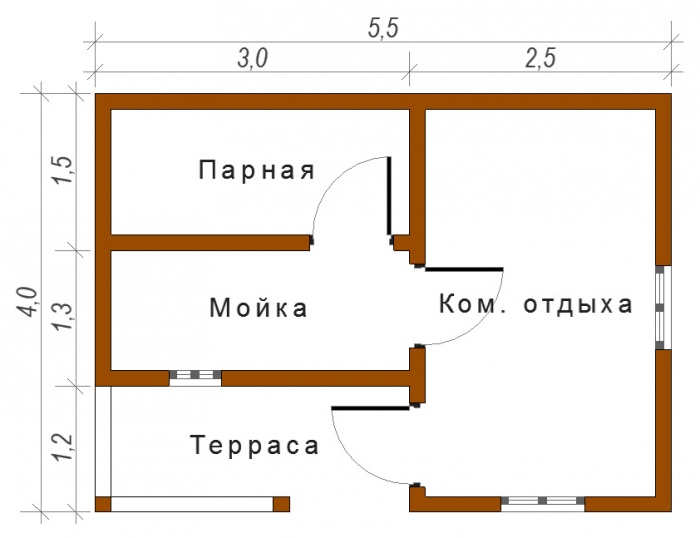

- way of fixing the timber;

- floor and ceiling mounting option;

- the design of the stove for the bath and the features of its installation.

Comment! When choosing ready-made construction projects, take into account the type of soil and climatic conditions of the region in which the construction of the bath is planned.

With design skills, you can draw up your own bath plan. Ordering drawings from a specialized company is another option for preparing for future construction.

Indicative list of materials

The construction of a bath will require the availability of materials, the volume of which depends on the chosen project. Here is an indicative list required for arranging a bath:

- Beam with a section of 15/15 cm.

- Floor mounting board. Optimally for these purposes, an edged board with a length of 4 m and dimensions of 15/5 cm is suitable.

- The ceiling surface is sheathed with clapboard 2 cm thick, the width of which is 10 cm.

- Arrangement of decorative finishes inside the bath is recommended to be carried out with a similar material.

- Competent construction provides for the formation of steam, hydro and thermal insulation. For these purposes, a vapor barrier film, penofol or plastic film is purchased as waterproofing; mineral wool is perfect for insulating the ceiling surface.

- The surface of the bath will be protected from high temperatures by sheet asbestos. Installation is carried out on the walls and ceiling near the stove, as well as in the chimney area.

- Depending on the chosen method of building the foundation, you will need components for concrete mortar and materials to form a columnar structure.

- The finishing coating of the bathhouse roof is often focused on finishing the main building or related buildings in order to create the overall harmony of the site.

- Insulation for mezhventsovy seams. When building a bath, jute, tow, moss or flax felt are suitable for these purposes.

Advice! It is better to start building a bath in spring, this will allow the wood to settle in the next six months break. The purchase of cement is carried out immediately before the start of the construction process so that it does not lose its qualities.

The main stages of arrangement

The laborious construction process is unlikely to be complete without the involvement of diverse specialists. Work begins with the arrangement of the selected site for a bath, freeing the soil from debris, roots and other elements that impede construction.

Laying the foundation

There are three main options for building a foundation for a bath:

- Columnar. The most popular option when building a bath from a bar. Let's dwell on the rules of its arrangement in more detail.

- Pile-screw. Refers to a type of columnar foundation. The characteristic features of its construction are the speed of the process and insignificant material costs.

- Tape. It is used for the construction of a bath in rare cases due to its high cost and labor intensity. The significant weight of the building or problem soil are the main reasons for choosing a strip foundation.

If we are building a bathhouse on swampy soil, it will save the structure from premature destruction, but be prepared for serious expenditures of funds and efforts.

The process of building a columnar base support for a bath includes the following steps:

- Recesses for the supports are prepared. The spacing between the posts is determined based on the total load on the columnar structure, taking into account the characteristics of the soil. The corners of the bath and the intersections of the walls are the obligatory points for installing the pillars.

- The approximate depth of the holes is 1.0-1.5 m. The value varies based on the level of soil freezing.

- At the bottom of each recess, a cushion of sand and crushed stone is being arranged with a layer of 10-15 cm.

- The next stage in the construction of the foundation for the bath is the installation of asbestos pipes with strict adherence to the vertical level.

- Inside the supports, for the purpose of reinforcement, metal rods are placed, which are poured with a concrete mixture in three stages.

- The space around the pipes is also filled with concrete mortar.

- After several days, construction continues with the formation of a half-brick wall between the supports of the bath.

Erection of walls and roofs

After arranging waterproofing on the foundation in the form of 2-3 layers of roofing material, they proceed to the construction of the walls of the bath. For construction, a beam with a section of 15/15 cm is traditionally chosen. The first crown made must be checked for all parameters.

Advice! It is optimal when the first crown is at least 30 cm from the ground.

Arrangement of walls is most often carried out by the "in the paw" method. If the quality of the timber is in doubt, the rows of the walls of the bath are connected with dowels. This construction method will prevent displacement and twisting of the wood material. The installation of wedges is carried out according to the brickwork method: piercing through 2-3 rows, skipping one. It is optimal when the gap between adjacent pins does not exceed half a meter. The arrangement of the walls of the bath is accompanied by the laying of insulation between the beams. During construction, do not forget to leave window and door openings.

After the completion of the arrangement of the walls of the bath, the rafters are fixed taking into account the features of the selected roof configuration:

- The construction of a pitched roof involves fixing the rafters with two external supports. The second option of arrangement is to fix the roof of the bath with external and internal support.

- When installing a gable roof system, the lower edges of the rafters firmly rest on the walls of the bath, the upper edges of the elements form a roof ridge.

Installation of rafters to the last crown of the bath walls is carried out with staples. After arranging the rafters, they proceed to fixing the lathing. The construction of a bath with your own hands at all stages is accompanied by the laying of insulating layers that prevent heat loss, steam and moisture penetration, which provokes premature deterioration of the base material. This rule also applies to the arrangement of the roof. After fixing the insulation, steam and waterproofing, proceed to the installation of the decorative roof covering.

At the next stage of construction, they are engaged in the installation of window frames and doors.

Installation of communications

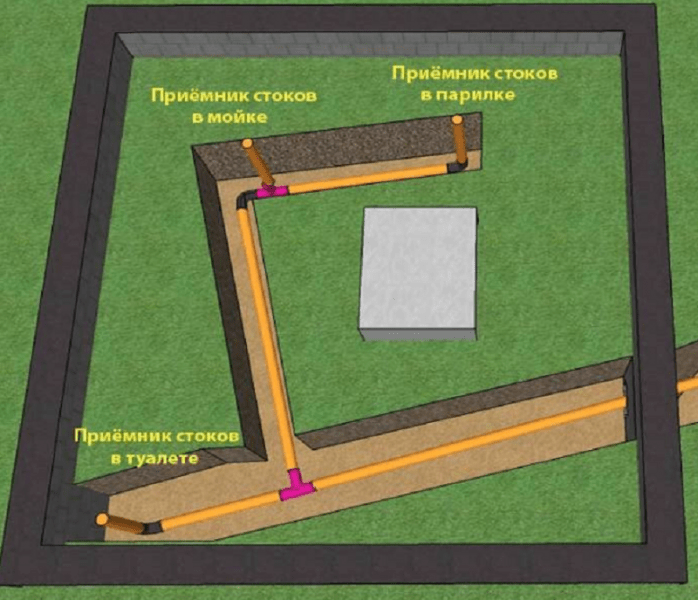

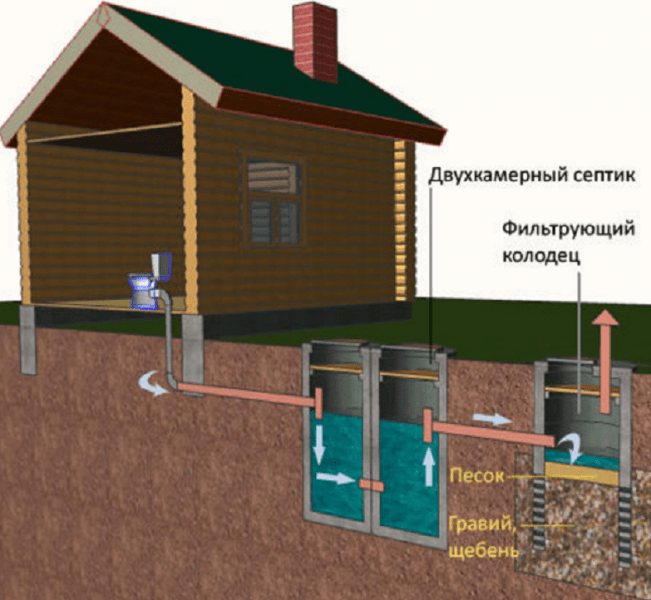

Then they move on to the arrangement of communications. The formation of the wastewater system begins at the stage of foundation construction. For this purpose, outside the building, a drainage well or a pit is being arranged, which are connected to the bath with a pipe. Remember to provide a slope in the drain system to prevent stagnation of sewage waste. How to make a competent drainage system is shown in the following diagram:

After the formation of the sewage system, they proceed to the arrangement of the floor. During the construction of a bath, two options for installing the floor surface are common: using concrete or wood. The first option is more durable, but labor and material costs for construction increase significantly. In addition, the arrangement of a concrete floor in the bath significantly increases the weight of the entire structure. Surface cladding in this case is carried out with tiles.

When arranging a wooden floor, it is made leaking. Construction technology is as follows:

- The lag is being installed.

- Boards are fixed on the logs with a small gap.

- For drainage, you can make a compact hatch, which is closed with a grill.

- The flooring is designed with a slope, allowing moisture to accumulate in the hatch.

The construction of a wooden floor in the bath is shown below in the photo:

Comment! Extending the life of wooden floors will allow thorough ventilation of the room after each visit.

The next steps in arranging a bath

- installation of insulating materials on the surface of the walls;

- construction of a water supply system;

- electricity supply.

Steam room equipment

One of the most important stages of construction is equipping the steam room with a stove. The place of its installation is planned in advance. The light construction of a timber bath is unlikely to withstand a heavy brick stove with a massive chimney. In this case, an additional foundation is required. Usually they resort to the option of mounting a metal model. Protection of adjacent surfaces with screens reflecting radiation of high temperatures is a prerequisite for construction. An approximate scheme for arranging a stove in a steam room is presented below:

The construction of comfortable shelves does not present any particular difficulties: initially, the support frame is being installed, then boards are nailed to the installed support. Fastener caps are carefully recessed in depth to avoid burns.

Conclusion

The final touch of the arrangement is filling the bath with all kinds of accessories. Brooms, tubs, buckets, grates - all the wooden surroundings contribute to the formation of the traditional atmosphere of the Russian steam room.

Despite the laborious construction process, the result will be the pride of the owner and the delight of all invited visitors.

The most serious should be taken to the issue of interior decoration of the bath. While the room may look quite unremarkable, there are several important aspects to be aware of when it comes to finishing.

Of course, such a room must easily withstand high temperatures. In the bath, the air temperature can reach 120 degrees Celsius. Thus, you need to responsibly carry out all construction work, as well as choose materials that are suitable in terms of quality and scope of use.

At the same time, the finishing materials must "breathe", otherwise moisture will accumulate in the bath, which also negatively affects the state of the entire room. On sale you can find many interesting options for finishing materials that can be freely used during the construction of a bath.

In this article, we will dwell in detail on each issue related to the decoration of bath rooms. Moreover, we will carefully analyze all the materials that are used in this process.

Materials for interior decoration of the bath

Many experts in the construction industry have recognized that the best finishing material available in stores today is clapboard (or sheathing panels). Despite the general simplicity of the material, it is really capable of "breathing", but at the same time the lining perfectly maintains the optimal temperature inside the room. The lining shows itself especially effectively together with heat-insulating materials.

Another positive side of the classic lining is the ease of installation. Accordingly, for these works it is not necessary to involve specialists who usually ask for a lot of money. A beginner will also cope with all the tasks, but first it is worthwhile to study in detail all the subtleties of the process.

Clapboard can be used to decorate all walls and ceilings without any problems. As a result, we get an excellent sauna room suitable for a park. In this case, the material will not lose its initial properties. However, it is still necessary to carry out periodic maintenance of the wood, otherwise you may encounter numerous problems (cracking, deterioration of thermal insulation).

It is important to know that varnishes and stains cannot be used as protective coatings for cladding panels. Practice shows that these materials have a detrimental effect on human health. We are talking about those cases when the finishing material is exposed to high temperatures.

The choice of wood for finishing the bath

First of all, you need to know that the quality of the finish directly depends on the quality of the wood. When buying a lining, you need to pay attention to the condition of the material. If there are any notches, scratches or other damage, it is better not to even look in the direction of such cladding panels. Gradually, they will deteriorate and eventually the lining will have to be replaced.

In addition, the surface of the lining should not be wet. This suggests that the technology for the production of this material has been violated. If the lining still has a little moisture, you should dry the wood.

In such construction work, deciduous lining is often used. As a result, we will have a high-quality finish that will not heat up along with the entire room, but at the same time the wood will retain heat in the bath when necessary. In this case, you still have to monitor the condition of the material so that it does not become unusable for various reasons.

Often, linden panels are chosen as finishing. This is an excellent wood, but gradually the surface of such panels begins to darken. After some time, the appearance of the material will create a not very pleasant atmosphere. To avoid this characteristic change in wood, the surface should be treated with special coatings. They are often sold in hardware stores. In this situation, the linden material will always have the same attractive shade. Linden is also good because it heats up very slowly, and for a bath this is a very important aspect.

Birch is rarely used as a finishing material. The point is that birch often dries out strongly, so after a while it loses its initial appearance. You cannot do without protective coatings here.

Sometimes builders call aspen the best finishing wood. It is most optimal to use aspen lining as a finishing material for the ceiling. With the right approach, this type of wood becomes incredibly strong and durable. Of course, similar results are achieved by pre-treatment as well as proper drying. Done correctly, aspen can be freely used as a ceiling covering. Many builders claim that often aspen is so strong wood that it is almost impossible to hammer a nail into it. Accordingly, it will not work to damage the tree either.

Wall arrangement process

Let's dwell on the finishing of the floor and walls of the bath in more detail. As we have already said, in the overwhelming majority of cases, lining is used as a finishing material. Accordingly, the finishing process consists of several stages, which are given below.

- At the very beginning, a full-fledged project is drawn up. If all is well, then in the end we will be able to roughly estimate the required volumes of finishing material. To do this, you need to measure the dimensions of all the necessary surfaces and make elementary calculations.

- Next, the lining is selected. It should be borne in mind that there are many options for this material on sale, so the dimensions of the panels should be taken into account even during the calculations of the project. In this case, the dimensions of the lining should be well combined with the dimensions of the bath room.

- Now on the surface where the lining will be located, the vapor barrier is attached. This is necessary in order to retain steam and prevent it from entering the already equipped thermal insulation. The vapor barrier is attached to surfaces with construction tape. No damage to the material, as well as gaps between the insulation strips, must be allowed.

- Next, the crate is equipped, on the basis of which the lining will be fastened. Accordingly, wooden blocks that can withstand the weight of the finish are attached along the entire perimeter. Cleamers are used directly for fixing the lining. They will make it possible not only to quickly install the finishing material, but also to quickly dismantle it, if there is such a need in the future.

- Well, at the very end, the final processing of the wood finish takes place. The essence of this stage of work is that you can often find untreated wood on sale. In order to obtain the highest quality result, the final processing takes place after the installation of the lining, since the wood can be damaged during fastening. Already after the lining is located on the walls, you can easily apply all the necessary protective layers. This is not only convenient, but also as efficient as possible: each panel is visible, and the light source will allow you to view the entire surface with high quality.

There are tons of finishes on the internet that can be used in a variety of spaces. This gives a certain freedom of choice, allowing you to create your own original bath. Of course, when choosing options, one should proceed from the fact that the bath room has a number of features that should be considered when choosing a tree species, as well as building resources.

At the same time, based on the selected wood, you can create some other objects inside the bath. For example, it can be shelves, tables or chairs. Accordingly, in such conditions, we can create a single style of the room, from which everyone will definitely be delighted. It is also worth understanding that you cannot save on the bath. This is the room that should be distinguished by a warm atmosphere and coziness, despite the fact that they only come to the bathhouse to take a steam bath.

Features of floor finishing

Floor finishing is an equally important aspect that should be paid special attention to. The point is that a high-quality surface should provide an even more comfortable atmosphere that will emphasize the quality and durability of the entire bath room.

However, the process of finishing the floor itself can be quite simple. Considering the fact that we have a relatively low temperature at the floor level, here you can use wood, tiles, and many other materials. Of course, it is advisable to make sure that all the components of the room are well combined, because the bathhouse is a special space.