Machines for grinding meat and meat grinder fish. Meat and Fish Processing Equipment Equipment for Meat and Fish Processing

Refresh

yandex Market data from 02/16/2020 00:00

Description:

The electric meat grinder "Lepsa Gamma-2MC" can easily prepare meat or fish minced mini in a few minutes. The electromazor has one nozzle: for the preparation of meat, fish or vegetable minced (shallow, medium and large cutting). Two-way cutting knife made of high-quality steel. High performance with small power consumption. Patented three-element cutting knot for meat processing. Comfortable and fast replacement of consoles in the electric drive.

Description:

Article No. 322969 The meat grinder is a tool for grinding not only all types of meat, but also fish, vegetables or other products. Electric meat grinder Bosch MFW68680 with a capacity of 2200 W is designed to facilitate the life of housewives, tired of traditional handmade grows. After all, if earlier the amount of minced meal twisted by hand, depended only on how speed you rotate the handle, then Bosch is ready to produce a much more product in one minute without extra effort.

Description:

Electromasor Lepse "Gamma-7-01" Set 4: Meat grinder (preparation of meat, fish and mushroom minced small or large logging); Power supply, in: 220 Frequency, Hz: 50 Maximum power, W: 700 Performance (by meat), kg / h: at least 40 Mode of operation: 30 min - work, 30 min - Break Net weight, kg: 3 Mass gross , kg: 4.3 Dimensions, mm: 300x160x260 Warranty, ME: 12

Description:

Article No. 231975 The meat grinder is a tool for grinding not only all kinds of meat, but also fish, vegetables or other products. Electric meat grinder Unit UGR-460 is designed to ease the life of housewives tired of traditional handmade meat grinders. After all, if earlier the amount of minced meal is twisted manually, depended only on how speed you rotate the handle, then the UGR-460 is ready to produce a much more product in one minute without more effort.

Description:

Application areas: Cooking minced meat, birds and fish. Features: The model is equipped with a quiet engine, adapted to high loads. Replaceable lattices with holes of different diameters allow you to adjust the degree of grinding of raw materials. The housing and all parts are made of stainless steel. Characteristics: Meat grid diameter: 70 mm Diameter of lattice holes 6 and 8 mm Options: 1 Spare grille 1 Spare knife.

Description:

Electromasor Lepse "Gamma-7-01" Kit 2: Meat grinder (preparation of meat, fish and mushroom minced small or large logging); Vegetable cutter (grater, shredding, cutting of vegetables, fruits, chocolate, cheese, nuts); The screw juicer of Lepse "Gamma-SV" (preparation of juice from vegetables and fruits). Power supply, in: 220 Frequency, Hz: 50 Maximum power, W: 700 Performance (by meat), kg / h: at least 40 Mode of operation: 30 min - work, 30 min - Break Net weight, kg: 3 Mass gross , kg: 4.7

Description:

Electric meat grinder M14.01 Designed for making minced meat, fish, mushrooms. Wear-resistant knife made of high-quality chrome steel has saber-shaped cutting edges that provide the smoothness of the meat grinder and increase the quality of product recycling. The special design of the screw chamber with spiral guides and a screw shape provides optimal product supply to create the best cutting conditions even low-grade meat.

Description:

Electric meat grinder M35.02 of high power can easily cope with meat of any quality. Designed for making minced meat, fish, mushrooms; Grinding vegetables, fruits; obtaining puree masses from berries; Test profiling. Manufacturer's warranty 3 years. Reverse function. Durable and sharp knife with a saberoid edge. Convenient storage compartment cord and lattice. Carrying handle. Legs of non-slip elastic material.

Description:

Application areas: Cooking minced meat, birds and fish. Features: Equipped with a standard meat grinding system that crushes meat once for each passage. The powerful engine provides processing to 2.7 kg / min. Reverse function. The meat grinder has a durable aluminum housing. Complete set: 1 knife 3 stainless grilles (hole diameter 3, 4.5, 8 mm) 2 nozzles for sausages boot tray pusher.

Description:

Electric meat grinder M35 high power can easily cope with meat of any quality. Designed for making minced meat, fish, mushrooms; Grinding vegetables, fruits; obtaining puree masses from berries; Test profiling. Manufacturer's warranty 3 years. Reverse function. Durable and sharp knife with a saberoid edge. Convenient storage compartment cord and lattice. Carrying handle. Legs of non-slip elastic material.

Description:

Application areas: Cooking minced meat, birds and fish Features: Material Tray: Stainless steel Material Material: Chrome Metal Package: Boot tray Pusher 2 knife and 2 lattices

Description:

Electric meat grinder M34.03 of high power can easily cope with meat of any quality. Designed for making minced meat, fish, mushrooms; Grinding vegetables, fruits; obtaining puree masses from berries; Test profiling. Three lattices with holes of various sizes included in the package allow you to obtain mince of various consistency. The grille with the holes of the oval shape will help to prepare the cold and cut into small pieces of meat or vegetables.

Description:

Full description: Meat grinder Rotor Extra-R EMSH 35 / 250-4 Electric meat grinder Rotor Extra-p EMSH 35 / 250-4, the maximum power of which is 1500 W, and the nominal - 250 W will be able to become an indispensable assistant in your kitchen. The performance of the presented model makes it possible to handle at least 0.58 kilograms of products per minute. The meat grinder is designed to prepare meat and fish minced meat, and can also be used as a vegetable cutter (a special nozzle is included in the package

Description:

Full Description: Meat grinder Rotor Alpha-R EMSH 35 / 250-4 Electric meat grinder Rotor Alpha-P EMSH 35 / 250-4, the maximum power of which is 1500 W, and the nominal - 250 W can become an indispensable assistant in your kitchen. The performance of the presented model makes it possible to handle at least 0.58 kilograms of products per minute. The meat grinder is designed to prepare meat and fish minced meat, and can also be used as a vegetable cutter (a special nozzle is included in the package - Small

Description:

Article No. 231971 The meat grinder is a tool for grinding not only all types of meat, but also fish, vegetables or other products. The Unit UGR-457 electric meat grinder is designed to ease the life of housewives, tired of traditional handmade grows. After all, if earlier the amount of minced meer is twisted by hand, depended only on how speed you rotate the handle, then UGR-457 is ready to produce a much larger product in one minute without more effort.

Description:

Full description: Meat grinder Rotor Alpha EMSH 35 / 250-2 Electric meat grinder Rotor Alpha EMSH 35 / 250-2, the maximum power of which is 1500 W, and the nominal - 250 W can become an indispensable assistant in your kitchen. The performance of the presented model makes it possible to handle at least 0.58 kilograms of products per minute. The meat grinder is designed to prepare meat and fish minced meat, and can also be used as a juicer for berries, soft vegetables and fruits (in the package

Description:

Electric meat grinder M34.04 increased power can easily cope with meat of any quality. Designed for making minced meat, fish, mushrooms; Grinding vegetables, fruits; obtaining puree masses from berries; Test profiling. Three lattices with holes of various sizes included in the package allow you to obtain mince of various consistency.

Description:

Full Description: Meat grinder Rotor Alpha EMSH 35 / 250-4 Electric meat grinder Rotor Alpha EMSH 35 / 250-4, the maximum power of which is 1500 W, and the nominal - 250 W, can become an indispensable assistant in your kitchen. The performance of the presented model makes it possible to handle at least 0.58 kilograms of products per minute. The meat grinder is designed to prepare meat and fish minced meat, and can also be used as a vegetable cutter (a special nozzle is included in the package - Small

Description:

Full description: Meat grinder Rotor Maxi Emsh 35/300-1 Electric meat grinder Rotor Maxi EMSH 35 / 300-1, the maximum power of which is 1500 W, and the nominal - 300 W will be able to become an indispensable assistant in your kitchen. The performance of the presented model makes it possible to handle at least 0.58 kilograms of products per minute. The meat grinder is designed to prepare meat and fish minced.

Description:

Full Description: Meat grinder Rotor Extra-R EMSH 35 / 250-1 Electric meat grinder Rotor Extra-p EMSH 35 / 250-1, the maximum power of which is 1500 W, and the nominal - 250 W will be able to become an indispensable assistant in your kitchen. The performance of the presented model makes it possible to handle at least 0.58 kilograms of products per minute. The meat grinder is designed to prepare meat and fish minced.

Frash dishes have always been popular in catering establishments. And in fact, none of the canteen menu costs without a boiler, zrazov, bugs, dasses! And to prepare them in the desired quantity, a lot of minced is required. And here the electric center comes to the rescue - an indispensable kitchen equipment.

It is already difficult to imagine a cook, who enthusiastically turns the handle of the mechanical meat grinder in the kitchen of the restaurant, where the minced meat is used not only in the usual cutlets, but also in the dishes of kitchens of many nations of the world.

Electric meat grinder in the cooking kitchen

Industrial meat grinders in catering kitchens appeared in the 50s of the last century. This is one of the types of meat processing equipment. Possessing a powerful engine, such meat grinders are treated to 100 kg of meat per hour.

The details of this professional equipment are made of or steel, because of this they weigh a lot, and in professional kitchens they are installed stationary in one place. The cast iron is not wearing, and therefore the device has a long life. In addition, such details enable the machine to work for a long time without a break.

These meat grinders have several knives that serve for the production of stuffing of different levels of grinding. The devices have non-removable fuses, they exclude injury to the operator.

Meat grids have additional features:

- sifting flour;

- loose flour and dough;

- grinding and cutting of vegetables;

- nozzles for squeezing juice;

- nozzles for the manufacture of baths;

- nozzle Reverse for a very fine grinding, designed for sausages and sausages;

- nozzle for the manufacture of pasta paste;

- slicer;

Main species

Standard meat grinder Designed for processing raw meat, fish in different degree of grinding. This is their only basic function. Such a meat grinder join nozzles  for a variety of additional features.

for a variety of additional features.

The meat grinder is capable of processing frozen meat into mince, during such a processing, the products remain fresh, protein compounds are not deformed, meat fibers are not disturbed.

The principle of operation of this equipment is sufficiently simple: meat is placed in the loading device, which passes through knives, where its primary grinding occurs, then the mass takes place through a venee through a special matrix, and acquires the necessary consistency. In such a tip of auger, there may be several, which speeds up the processing process. Wipes differ from conventional meat grinders and externally. They have a fully closed case having a rectangle shape.

By the method of placement of the meat grinder there are two types:

- the first are installed on the floor, have special legs that are included; These are heavy devices, have a powerful engine, recycle a large amount of raw meat;

- the seconds have lower power, and therefore, smaller weight are installed on tables or stands.

Meat grinders are classified and by type of knives installed in them:

- enterprises - a traditional knife set: grille, auger and one-sided knife, the same as in a home grinder; Meat grinders with such a set acquire for small cafes and canteens;

- semi-gunger - in this version, except the augers and lattices, there is a double-sided knife and cutting knife; Such meat grinders are in restaurants or other major catering establishments;

- unger - there are two lattices, two bilateral knives, two cutting, usually having a shape of a tribal; This device is bought for specialized institutions, which are preparing constantly mince for bathamas, sausages and sausages.

How to choose the right industrial meat grinder

When buying such equipment it is necessary to take into account several conditions:

- all items that come into contact with the products must be made of food steel;

- such details should be easily removed;

- a good meat grinder must have a function "Reverse", which will prevent winding at the auger of the veins;

- the diameter of the lattice: the quality of the final product depends on it and its taste;

- the number of knives is important - than them are more, the higher the rate of meat processing and better quality;

- there must be a device that protects the motor from overheating;

- it is worth considering the necessary complete set;

- it should be taken into account that companies, indicating performance, overestimate it almost twice;

- if you need a silent meat grinder, then you should pay attention to the gearbox with an oil bath.

Overview of popular models

Specifications:

- material: Food Steel;

- reverse: yes;

- power: 1.9 kW;

- voltage: 400 V;

- grate diameter: 82 mm;

- productivity: 300 kg / h;

- the diameter of the loading neck: 40 mm;

- dimensions: 690x420x450 mm;

- weight: 51.5 kg.

Price: 46 000 rubles.

Feedback: Ivan Sergeevich, Owner of the roadside cafe "Route", Krasnodar Territory:

- In our cafe dishes from minced meat - the main one. Drivers need to eat satisfying and inexpensive. Therefore, we prepare the cutlets and bokings, now added the dumplings in the menu, and for all this it is necessary to nour stuffing. Already the year helps the electric center, the MEP-300 brand, when I bought, did not think about performance or additional options. But bought and not disappointed.

The company "Chuvashtorgtekhnika" Russia.

Specifications:

- material: stainless steel;

- voltage: 380 V;

- power: 1 400 W;

- execution: Outdoor;

- regulating legs;

- full Unger;

- dimensions: 410x560x690 mm;

- weight: 47 kg;

- productivity: 150 kg / h.

Price: 42 800 rubles.

Feedback: Alena (Nick Kucharenka):

- "Prepare - for me a vocation. Kitchen ─ This is my element, so I am glad that the owner caught the sane, from the first left, because I did not understand that for such a work it is necessary for the fantasy of a strict technological, and this understands and therefore almost does not interfere, the main thing is that everything is in order. Last year I put a condition: we buy an industrial electromagnet. Prior to that he used the usual household meat grinder and a kitchen machine. And here the production has increased, and looked at the classmates - industrial gives mince better quality. The Meep-150 meat grinder was ordered in the online store. I am all evening on all the internet shops of Lazala. But I like the car. The main thing is not more difficult than the household. I do not really understand the technique, so it is important for me that the machine was without frills. "

Meat grinder jr-120

Harbin Commercial Machine-Building Company "Golden Happiness", China.

Specifications:

- processes frozen to -7 degrees meat;

- power: 11 kW;

- voltage: 380 V;

- productivity: 2 t / h;

- the diameter of the matrix: 120 mm;

- shneck rotation: 190 rpm;

- weight: 300 kg;

- dimensions: 1050x750x1300 mm.

Price: 369 000 rubles.

Feedback: Ivanov Sergey, Owner of the sausage shop:

- "In such a production, the top is needed first. I have a JR-120, Chinese in my workshop. I'm not going to change yet. With large volumes copes. "

Industrial meat grinders are produced today by many companies specializing in the production of electromechanical equipment for catering. The meat grinders are distinguished by the shape and number of knives, power, performance, additional equipment, design, placement conditions. The owner remains only to make the right choice: to choose a meat grinder that is the most appropriate in the parameters of its public catering.

Chapter 4.

Meat and Fish Processing Equipment

Classification of equipment for processing meat and fish

At catering facilities for meat and fish processing, the following equipment is used: meat grinders, minced meat, meat makers, fishers, boiler-forming machines and universal drives for meat shops with a set of replaceable actuators to them.

Currently, meat grinders are widely used: with manual drive - MIM-60, with an individual electric motor - MIM-82 and MIM-105; Replaceable meat grinders to universal drives PU-0.6 and PG-0.6 - MSG-150 and SMG-70 (150 and 70 - the performance of meat grinders, kg / h).

All meat grinders are denoted by letters of Mime, which means "Machine grinding machine", and numbers corresponding to the diameter of the knife grid (mm).

Main sackers are designed for stirring the minced meat and its components in a homogeneous mass and enriching it with oxygen by air, which ensures the formation of minced meal and the cutlet mass of high quality. At catering facilities use individual-actuators, as well as MC8-150 stainless steel as a shift mechanism to a universal drive.

Machines for loosening meat are used to cut the surface of the portion pieces of meat to destroy the fibers of the connective tissue. Such pieces of meat during heat treatment are less deformed, fasterly plot and are obtained more juicy and soft. In catering enterprises, MRM-15 meat rippers are used with individual drive, as well as MS-19 as a shift mechanism to a universal actuator PU-0.6.

Currently, the MFC-2240 brand machine is used for molding, which is not only cutlets, but also produces breading on one side.

To remove scales from fish in catering enterprises, the PO-1 felt is used with an individual drive of IC-17-40 as a replaceable mechanism to a universal PM-1.1 drive.

For the preparation of meat and fish meat boiler in meat shops, universal special-purpose drives with a set of replaceable mechanisms of the first and second performances are used.

Meat grinders

Meat grinders are designed to grind meat and fish. In catering enterprises, the MIM-82 and MIM-105 meat grinders received widespread use.

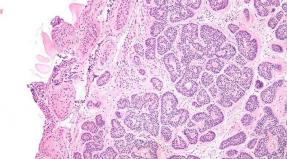

MM-82 meat grinder (Fig. 4.1) is a desktop machine with an individual fastening. It consists of a housing, processing chambers, a boot device, auger 9, working agencies, as well as the drive mechanism and the mechanism of the machine.

The pig-iron housing of the meat grinder is lined with steel stainless steel sheets, in which the openings for cooling the electric motor are located.

The working chamber of the machine on the inner surface has screw cuts that improve the flow of meat and exclude the rotation of it with the screw. On the top of the case there is a boot device, which is installed on the safety ring 10, eliminating the possibility of hand to get into the working bodies of the machine during operation. The meat grinder is equipped with three lattices with holes with a diameter of 3, 5 and 9 mm, cutting grille 8 (25) and two double-sided knives 22 and 24.

Knives and grilles are put on the auger in the sequence specified in Fig. 4.1, b, and in the assembled form tightly pressed to each other with a clamping nut 6.

Inside the working chamber is auger 9, which is a one-anterest worm with a variable step of turns and serves to capture meat and feed it to knives and lattices. A screw on one side has a shank with a spike, through which he gets rotating from the drive, on the other hand he has a finger with two chamfer, which is installed knives and grids. The lattices in the working chamber are fixed, and the knives rotate together with the screw.

Fig. 4.1. MM-82 meat grinder:

a - scheme; B - Workers Instruments: 1 - Base; 2 - electric motor; 3, 7, 21, 23 - knife grilles; 4, 20 - Stubborn Ring; 5, 22, 24 - double-sided knives; 6 - clamp nut; 8, 25 - cutting grille; 9, 26 - auger; 70 - Safety ring; 11- pusher; 12 - bootable bowl; 13, 18 - gear wheels; 14 - shaft; 15 - ball bearing; 16 - cuff; 7 7, 7 9 - gears

First, the cutting grille is installed, which has three knives with cutting edges outward, then double-sided knife with cutting edges counterclockwise and a large lattice by any side. Next set the second double-sided knife, a fine grid, a stubborn ring and a clamping nut. The meat grinder drive consists of an electric motor 2 and a two-stage cylindrical cylindrical gearbox. On the side facing of the meat grinder there is a push-button panel with two control buttons: "Start" and "Stop".

Rules of operation of MM-82 meat grinder. Before turning on the machine, it is necessary to make sure that the housing of the meat grinder is securely fixed, and the clamp nut is not tightened. After checking the reassembly (ground) and turn on the electric motor, you should wrap the nut before the advent of the noise increases. Meat or fish, pre-chopped by pieces weighing 50 ... 200 g and freed from bones, tendons and films, pushed with a wooden pusher into the loading neck. At the same time, it is forbidden to strongly press the product to a screw, as it can cause an overload and output of the electric motor. The flow of meat should be uniform, without much effort. With long-term operation, the meat grinder must be stop periodically, and clean the knives and grilles from the tendons.

It is forbidden to use a meat grinder without loading, as it accelerates wear and knives, and lattices. It is not recommended to grind in the meat grinder of crackers, sugar or salt, because these products lead to rapid wear and blurring of working bodies.

It is impossible to work with a meat grinder without a safety ring and leave it while working unattended.

After completing the work, the machine is turned off and disassembled. To extract a screw, knives and grids from the working chamber of the meat grinder use a special hook. All parts are purified from minced residues, washed with hot water and dried.

After drying the auger, knives, lattices and the working chamber are lubricated by unsalted food.

When assembling, special attention is paid to the proper installation of working bodies, knives and gratings, since in the case of incorrect assembly, the output of the machine fails.

It should be remembered that if the clamping nut is tightened, the knives are too much pressed against the lattice and during operation as a result of the friction of the metal heated and fail.

Fig. 4.2. Meat grinder MIM-105:

1 - electric motor; 2 - working chamber; 3 - fixed nut; 4 - Stubborn Ring; 5 - clamp nut; In - auger; 7 - boot device; 8 - thrust ball bearing; 9 - Val sleeve, 10 - shaft; 11 - ball bearing; 12 ~ housing; 13 - Clinorem Transfer

Weakly screw the clamping nut is also undesirable, since in this case there is a gap between the knife and the grille and the cutting of meat occurs poorly; The quality and performance of the meat grinder are sharply reduced. One of the main conditions for the good work of the meat grinder is correctly sharpened and installed knives and grilles in the working chamber of the machine. Therefore, knives and lattices should be delayed or replaced by new ones.

The MIM-82M meat grinder on the device and operation is similar to the MM-82 meat grinder, but has a removable bootable bowl and a sleeve, which is convenient for quick disassembly and sanitary processing of the machine. Fixation of knives and grilles is carried out by a lever.

MM-105 meat grinder (Fig. 4.2) according to the design similar to the MM-82 meat grinder, but has some differences. It is installed on the floor and has significantly greater performance. The gearbox is connected to the electric motor of the clinorem transmission. The working bodies (knives and grilles) of MM-105 meat grinders are similar to the working bodies of the MM-82 meat grinder, only the diameter of its working chamber is 23 mm more, and the auger, knives and lattice are pushed out of the housing for a fork driven by a handle.

The rules of operation of MIM meat grinders, MIM-82M and MIM-105 are identical.

The MC2-70 meat grinder is given in the working state by universal GH-0,6 actors and PU-0,6, and the MC2-150 meat grinder is a universal PM-1.1 drive. According to the design, device and their operation, these meat grinders are similar to the MIM-82 meat grinder.

Possible malfunctions of meat grinders and their elimination methods are shown in Table. 4.1.

Recently remembered one funny case. Everything happened in a neighboring village, and told his dusty comrade of my mother-in-law, so this truly truthful story. And not Bayan - guaranteed!

Quarrel with inspector

The majority of fishermen today catch fish exclusively for your own pleasure, letting them down mostly in the reservoir. A small part of the fishermen is fishing with the aim of feeding (basic weight). But occasionally come across such gaps - the poachers, who for the forwards of 10 kilos, are ready to destroy the ton fish that they are not needed (it does not have great value) and they throw it in a nearby forest. Where the fish rotes.

Naturally, the fish inspector, as far as possible, try to fight such poachers and often, the innocent people fall under the damn - simple fishermen.

So, in the village there was one peasant-fisherman who fishes mostly for himself, but sometimes he slowed down a catch - the pension is not so good. Ichork Solil, also for myself and for a little for sale. Somehow it is necessary to survive. Completely without fanaticism. No damage to the water resources of Russia did not make a peasant, besides alone - it is simply unrealistic.

But one day, the demon was a man's tap: he climbed with one fish inspector for some reason and told him that he (inspector) Loch and he would never be able to catch him "on the hot."

And this law comes into force only when on the banks of the river Powan a fisherman with fish guns. Well, the inspector in support of colleagues also went to the principle - and at any convenient case, they check the man on the subject of the catch.

Cooked fisherman!

And now, somehow, they stop it along the road from the reservoir, and behind the peasons of the man's ships, liters for 35 - 40. We were delighted - they say, this time it was precisely caught!

Come on, open! And they themselves are standing! Well, the peasant opens, and inside the mince! The most common fish minced meat. Box, full minced fish! In the inspectors, the eyes on the forehead were climbing. In the legislation about the minced meal, the word is not said, because The penalty should be accrued by the number of tails. In addition, for the female one amount of the fine, for the porridge is completely different. There is nothing to present a fishing. I had to let go of the resourceful fisherman.

For fish minced inspector can not be presented!

A peasant is, when I realized that I got excited with my statement and I realized that he would not give the fishnadzor to him, and it was necessary to feed the family. Well, I came up with a meat grinder on the fishery. At the place of fishing built the table and twisted the caught fish right here in the mince. Boiler cooks! The story of a decent monologue - Michal Mikhalych Zadornov.

The technological process of cooking a large range of products from meat and fish is carried out on a variety of machines and mechanisms.

The beginning of production is primary processing of raw materials on washing and cleaning machines, as well as cutting frozen blocks and finished semi-finished products.

One of the main technological operations of processing meat and fish raw materials in food production is its grinding. Depending on the type of finished product, the grinding can be divided into large, medium and thin.

For large grinding produced cutting machines.

The average grinding is carried out with the help of -olchets, meat grids and courtters.

Colloid mills, emulsitators, disintegrators and homogenizers are designed to obtain minced fine grinding.

Measing machines and spares have various design solutions, but the fundamental device of the cutting assembly in all types of machines is equally (Fig.).

Fig. Schematic diagram of the cutting knot of meat and foaming machine: 1 - drive shaft; 2 - Sick-shaped knife; 3 - eccentric; 4 - plug; 5 - knife frames; 6 - lamellar knives; 7 - axis; 8 - angular lever; 9 - pusher; 10 - Fatherland

The cutting mechanism consists of flat knives fixed in the knife frame, and a planetary (sickle) knife. The planetary knife is fastened with a slotted compound on the main shaft of the machine and serves for transverse cutting of raw materials, pre-cut in the longitudinal direction of flat knives.

The block of flat knives is made in the form of a housing and two perpendicular frames with a set of knives. Thanks to the eccentric knives, the knives make reciprocating movement and cut the meat towards its feed.

The grinding of frozen meat blocks is carried out on various blocking machines of domestic and foreign production, the principle of action of which is mainly different only by the power effects of the working bodies on the product of guillotine, rotational, milling or combined mechanisms.

The guillotine mechanism consists of a fixed knife, rigidly fixed on the bed, and a movable knife installed in a rigid frame that makes a reciprocating movement. The guillotine mechanism cuts the frozen block on the layers with a thickness of 25 ... 55 mm.

Rotary mechanism is a rotating drum, on the outer surface of which flat knives are installed. Knives are cut off the block of meat pieces in the form of chips that enter the trolley located under the drum.

The grinding milling mechanism is two rotating towards each other shaft with a set of flat cutters. The meat block under the action of its own mass enters the zone of rotating cutters, where it is captured by milling and crushed.

Combined mechanisms intended for bilateral grinding of frozen blocks are a layout of blocking machines and wolfges.

Wipes are an extensive group of machines for medium grinding of meat raw materials. With the help of these machines, the primary grinding of the product is usually carried out before its further production.

To move the meat in the working chamber, feeding it to knives and pushing through knife grilles is a rotating auger with a pitch of turns, decreasing in the direction of the product unloading.

The cutting mechanism of the wolf consists of a fixed sub-cutting lattice, rotating cruciform knives, fixed knife grilles with holes of different diameters and clamping nut. The main technological parameter of the wolf is the size (diameter) of its lattice. Different machine brands are of size from 82 to 200 mm, which is included in the labeling of the last two digits (K7-FVP-82; K6-FP-120).

The degree of grinding meat on the wolf and its performance depend on the magnitude of the holes of the output grille and the number of cutting pairs (the grille - knife). With a minor degree of grinding (16 ... 25 mm), a single pair is sufficient - the top is collected with one knife and one grille; With a more subtle grinding (2 ... 3 mm), the number of cutting steam increases.

For cutting frozen meat and fishing, the MPZP machine is used (Fig.).

Fig. Machine for cutting frozen products MPZP: A - general view; b - kinematic scheme; 1 - supports; 2 - body; 3 - slave of the demummouft; 4 - the host of the half; 5 - knife; 6 - traverse; 7 - rod; 8 - guide strips; 9 - cast-iron column; 10 - crank shaft; And - lever; 12 - the inclusion mechanism; 13 - sliding swing; 14-ignition; 15 - product; 16 - Marzan; 17-table; 18 worm reducer; 19 - belt transmission; 20 - engine; 21 - Krivoship

The working bodies of the machine are the crank-connecting mechanism, a slide with a knife, a control panel.

When the machine is in a non-working position, the presenter and the slave coupling are open under the influence of an electromagnet on the spring mechanism. When the machine is turned on, the sliding key of the spring mechanism connects both half-guns and movement from the drive through the crank-connecting mechanism is transmitted to the slider, which along the guides, along with the knife, lowers down and cuts the product. In this case, the knife rests on Marzan (lining under the blade), inserted into the groove of the case, and then occupies the starting position.

The limit dimensions of the cut product of 180x380 mm. In order to avoid injury, the activation of the machine is carried out by simultaneously pressing two buttons.

To cut the meat semi-finished products of type AZA, a walk, kebabs, and the spicity use the M6-FRD machine. The machine consists of a welded bed, to which assembly elements and parts are fixed: planetary knife; block of flat knives; bunker; chief shaft; Right and left eccentric shafts; mechanical blocking; The neck and electrical equipment.

Meat in the cutting zone is supplied and subressive with a hydraulic cylinder, the operation of which is synchronized with the operation of the sickle disk knife. The length of the cut pieces is regulated by a special device, the magnitude of pieces is associated with the size of the knife frame. The machine includes the framework of the following sizes: 6x6; 12x12; 16 x 16; 24x24 mm.

To cut small-fiber meat and fish semi-finished products, use a type A-FL / 2 machine (Fig.).

Fig. Machine for cutting meat semi-finished products: 1 - feeding conveyor; 2 - tensioning device; 3 - casing; 4 is a chain transmission of the supply conveyor drive; 5 - feed conveyor drive; 6 - drive mechanisms of the longitudinal and transverse cutting of the product; 7 - the mechanism of transverse cutting of the product; 8 - product removal conveyor; 9 is the transverse cutting mechanism sensor; 10 - casing; 11 - mechanism of longitudinal product cutting

The machine consists of a feed conveyor, a mechanism for cutting meat and fish raw materials, a conveyor for the removal of the product, the beds.

The feed conveyor has a chain plate design with vertical stops, between which raw materials are laid.

The mechanism of cutting raw materials consists of plate and disk knives. Plate knives are fixed in two knife frames that make reciprocating movement in mutually perpendicular planes. The disk knife makes a complex movement in the plane perpendicular to the supply of raw materials into the plate knives. A command on cutting with a disk knife product is supplied by a special transverse cutting sensor.

The raw materials are loaded into the feeding conveyor, which serves it to knives. Plate knives cut the product on a bar. The dimensions of the cross section of the strokes are determined by the distance between the knives within.

When exiting the cutting zone of the plate knives, the product affects the sensor comprising a transverse cutting mechanism. Length of brooms is installed using sensors. The chopped raw material enters the discretionary conveyor, and the sensor occupies the original position. In the future, the cycle is repeated.

Machine performance 250 kg / h; The speed of the supply of 0.02 ... 0.03 m / s; Disclosure 0.09 ... 0.13 m / s; The frequency of rotation of the disk knife is 230 min -1; Rated power of an electric motor 2.8 kW.

In catering establishments for medium grinding of meat and fish raw materials, meat grinders of various types are used, the digital marking of which indicates the diameter of the knife grid in mm.

In fig. The structural scheme of the MIM-500 meat grinder is given.

Fig. Constructive scheme of MM-500 meat grinder: a - general view; 1 - base; 2 - drive shaft of the gearbox; 3 - body of the working chamber; 4 - sleeves; 5 - a set of cutting tools; 6 - pillage auger; 7 - Nut Caid; 8 - auger; 9 - fence; 10 - Tolkach; 11 - loading bowl; 12 - gearbox; 13 - cladding; 14 - clinorem transfer; 15 - electric motor; 16 - ejector; 17 - handle; b - kinematic scheme; 1 - clinorem; 2 - toothed cylindrical gearbox; 3 - auger; in - cutting tools

The main working body of the machine is a cutting mechanism consisting of four-colored knives, fixed sub-cut and knife grilles. Four-blade knives have cutting planes forming eight blades. Replaceable knife grid has three holes with diameters of 3.5 and 9.0 mm.

The operating chamber on the inner surface to prevent the product is preventing the profound screw channels. Promotion of raw materials in the mechanism is carried out by a screw with a decreasing step. In the machine case, a drive consisting of a 2.2 kW engine, belt transmission engine and a single-stage gearbox is enclosed. The capacity of the machine 500 kg / h, the speed of rotation of the screw 200 rpm.

MIM-105M meat grinder according to its constructive execution and the principle of action is similar to MIM-500, but has less productivity.

The catering meat grinders of the MIM-82M, MM-250, MM-82, M2 (764) type are widespread on catering enterprises. The fundamental difference is in constructive performance and individual specifications.

The MM-82 meat grinder consists of a working chamber and drive. The loading bowl has a pusher fuse. The drive consists of an electric motor and a two-stage cylindrical gearbox.

In the production of food, meat grinders of the MS2-150, MS2-70, MMP-H-1, UMM-2, which are replaceable actuating mechanisms of universal kitchen machines PM-1,1; PU-06; Pn; UMM-PV; PUVR-04.

In fig. Some types of meat grinders of universal kitchen machines are shown.

Fig. Meat grinders of universal kitchen machines: A - MC2-70 meat grinder; B - MMP-N-1 meat grinder; B - Meat grinder Umm-2

The quality of grinding and the performance of meat grinders depend on the state of the cutting tool. Its recovery is carried out by wipe. The side of the knife blade is sharpening on a sharpening machine.

In recent years, the domestic industry has established the release of high-quality M8M meat grinders, 8mm, M6M, 6mm, M4M, 4mm for shops, cafes, restaurants, canteens. The technical characteristics of this equipment are given in Table.

| Specifications | M8M | 8mm. | M6M | 6mm | M4M | 4mm. |

| Performance, kg / h | 250... | 300... | 250... | 300... | 250... | 300... |

| 300 | 350 | 300 | 350 | 300 | 350 | |

| Lattice diameter, mm | 70 | 82 | 70 | 82 | 70 | 82 |

| Installed power, kW | 1,1 | 1,1 | 0,75 | 0,75 | 1,1 | 1,1 |

| Capacity of the boot hopper, l | 6 | 6 | 6 | 6 | 10 | 10 |

| Supply voltage, in | 380 | 380 | 380 | 380 | 380 | 380 |

| Overall dimensions, mm: | ||||||

| length | 550 | 550 | 660 | 660 | 700 | 700 |

| width | 300 | 300 | 440 | 440 | 500 | 500 |

| height | 600 | 600 | 450 | 450 | 450 | 450 |

| Mass, kg, no more | 70 | 70 | 46 | 46 | 68 | 68 |

Special design and material of knives, as well as lattices provide continuous multiple operation of meat grinders without tool releasing. The lattice set allows you to vary the degree of grinding meat.

The use of a screw of the optimal form obtained as a result of computer simulation, in combination with other strictly calculated structural indicators, provides the most reliable and productive work with minor energy consumption.

Along with domestic equipment at catering establishments, meat grinders of imported manufacturing firms Fama - Italy, MKN - Poland, MTR - United Kingdom and others. Their compact execution is combined with great performance and ease of operation. As a rule, they are equipped with self-folding knives, and boot funnel complies with international safety standards.

Fig. Mechanism for cutting meat on Beefstoganov MBP-11-1:

a - general view; 1 - body; 2 - knife shaft; 3 - damper; 4 - comb; 5 - pusher;

b - disk mill

Replaceable executive mechanisms of universal drives Pn, Pu-06 are mechanisms for cutting meat on Beefstoganov MBP-11-1 (Fig.), MC19-1400 and MRP-P-1 meal.

Fig. Mechanism for cutting meat on Beefstoganov MBP-11-1: A - general view; 1 - body; 2 - knife shaft; 3 - damper; 4 - comb; 5 - pusher; b - disk mill

The working body of the IBE-11-1 mechanism is a packet of knife disks. The meat supplied by the pusher is cut into the slices and falls into the substituted container. The rotational speed of the shaft with knife mills 80 rpm, the mechanism runs from the phase voltage of 220 V.

The device and principle of operation of MC19-1400 and MRP-11-1 mechanisms are similar to the stationary meal MRM-15 (Fig.).

Fig. MRM-15 meal terminator: a - general view; 1 - machine hull; 2 - cover; 3 - carriage; 4 - gearbox; 5 - clinorem transmission; b - the gearbox housing; 7 - electric motor; 8 - microswitch; 9 - socket; 10-fork; 11 - capacitors; 12 - cord; 13 - Stanina; b - kinematic scheme; 1 - belt transmission; 2 - worm steam; 3 - cylindrical steam; 4 - Packages cutters

The meal consists of a hull, drive and a working body. The drive includes an electric motor with a clinorem transmission and a worm gearbox. Movement with disk gear knives is transmitted through a gear cylindrical pair. Packages of knives rotate in opposite sides. Breaking pieces of meat entering through the boot device are trimmed (frozen) on both sides.

Machine performance 1800 pcs / h; the frequency of rotation of the working shaft 90 min -1; power of electric motor 0.27 kW; Voltage phase 220 V; Overall dimensions 500x260x390 mm.

Developed and implemented for centralized production of culinary products Complex machines for portion pieces of MRPP-2000 meat.

For grinding, mixing, cutting, kneading, emulsation and vacuuming, minced meat is used by K-45 KB, VK-125.

The cutters are used for the final grinding of the previously spent processing on the wolfges of meat to produce fine-crushed meat raw materials, cutlet minced meat, patestone and other similar products.

The fine grinding of meat on the cutter is achieved by its cutting of the rapidly rotating cinema knives in the bowl rotating around the vertical axis. A bowl can be open or sealed. In the last version, the operation is called "Cutting under vacuum".

In fig. The kinematic scheme of the cutter is shown, characterizing the principle of operation of the machine.

Fig. Kitter kinematic scheme: 1 - electric motors; 2 - clinorem; 3 - gearboxes; 4 - bowl; 5 - discharge plate; 6 - knife head; 7 - knife tree

The receiving bowl is driven to rotation from the electric motor through the clinorem transmission and the worm gearbox. The knife head, console-mounted on a knife shaft mounted in rolling bearings, rotates from the electric motor through a clinorem transmission.

The finished product is discharged using a device that is a plate attached to the shaft, which rotates from the electric motor through the gearbox.

For mixing meat and fish minced meat with all the components provided by the recipe, are used aside.

The domestic industry produces a number of mixers of various performance, characterized by a constructive solution of individual nodes, but working according to one principle. The main working body of the machines are one or two rotating shafts with blades, which evenly mix the mince, saturating it with air. The mixing process, as a rule, does not exceed 60 s.

For catering enterprises, the most acceptable in terms of performance and consumption of electricity are FM-150, L5-FM2-U-35, LPK-1000F420.

The most simple device and reliability of work characteristic of this group of technological equipment has a pampering of L5-FM2-U-335.

The open-ended stainlessness consists of a bed, a messenger tank, where two auger, auger drive and the loading mechanism rotate towards each other. The rotation of the screws is carried out from the electric motor through the worm gear.

The loading mechanism consists of a trolley intended for transporting raw materials to the stash, and devices for its overturning, mounted in the bed.

The tipping device is a system of levers moving with a worm gearbox, with a separate electric motor.

The finished product is discharged through the hatches located at the bottom of the tank and manually open by the rotation of the flywheel clockwise.

To accelerate the stirring process, the machine design of the machine is provided by reversing the rotation of the screws, which is carried out by two buttons on the control panel.

For the production of dumplings, dumplings of the domestic production of NPA and NPA-1M are used.

The machines are continuous machines, in which, with manual loading of products, the bins takes automatic and waste-free sampling of the semi-finished product. They consist of a test bunker, filler bunker (for minced meat), quick-change molding nozzles molding drums and flourishing or lubricating devices.

The technical characteristics of dumplings are shown in Table.

More powerful in terms of performance (240 ... 1200 kg / h) are sub-2m, sub-zm and sub-6, intended for dosing and molding by dumplings.

Their structures differ among themselves only by the number of stamping drums. The main structural elements of the automata are: a ribbon conveyor; The loading hopper with a screw discharge of the test; The loading hopper with a paddle stirrer and an eccentric stuffing fastener; Painting and test collectors with molding device; Stamping drums with a lifting device; Bunker for flour with a tedder; Drive and Stanna.

The dough and mince from the bunker are injected into the appropriate collectors, and from them - into a forming device having two holes: outer - for dough and internal - for minced meat. From the molding device, a solid stream in the form of a filled tube exits the dough with minced meat and comes on trays or a ribbon from the corrosion-resistant steel and sprinkled with flour. Next, the tube arrives under the stamping discs. When moving the tubes on the conveyor, stamping drums are rolled along them, placing minced stuffing and dough on cells with simultaneous molding and bonding dumplings.

For purification fish Use MC17-40 and RO-1M1 mechanisms. The principle of their action is the same. The difference lies in the fact that the device MS 17-40 is a replaceable actuator mechanism of the universal PM-11 drive, and the RO-1M1 mechanism is produced with an individual drive, which is attached to the production table with clamp. Their performance is respectively 40 and 60 kg / h.

Flawlessness Doubleded PR-2M is designed to remove the dorsal, anal and tail fins among fish of different types and sizes.

The flavoring cutter consists of two heads mounted on the plate, and the electric motor for rotating disk saws. The saws are fenced with special shields having oval recesses and guide slots for the replenishment of fins under the saw. In the car there are two tray for removing the cut fins and the water is supplied for washing disk saws and trays.

The glowing machine is designed to remove the heads of the particle breeds of fish of different sizes. The working bodies of the machine are replaceable knives and three matrices for styling fish.

Knives are made in the form of a thin-walled cylinder with the end cutting edge. They are attached to the vertical shaft. The shaft from the drive mechanism performs the rotational and progressive movement down with the subsequent return and short-term stop at the initial position to replace the fish.

Conveyor Fishman Code KR-1 Designed for acceptance and cutting frostbed fish. It consists of a drive and stretch sections, a flux-cutting section and an inclined scraper conveyor.

The drive section includes the base, drive, cutting tables of fish, six jobs, waste disposal trays.

Bulcker is fixed on the basis of the stretch section. The bunker has three equalizers, two of which are still, and the third is adjustable in height and serves as a schiber. At every workplace there is a board for cutting fish and the water is connected. The capacity of the conveyor is 240 kg / h.